Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tinsmith Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

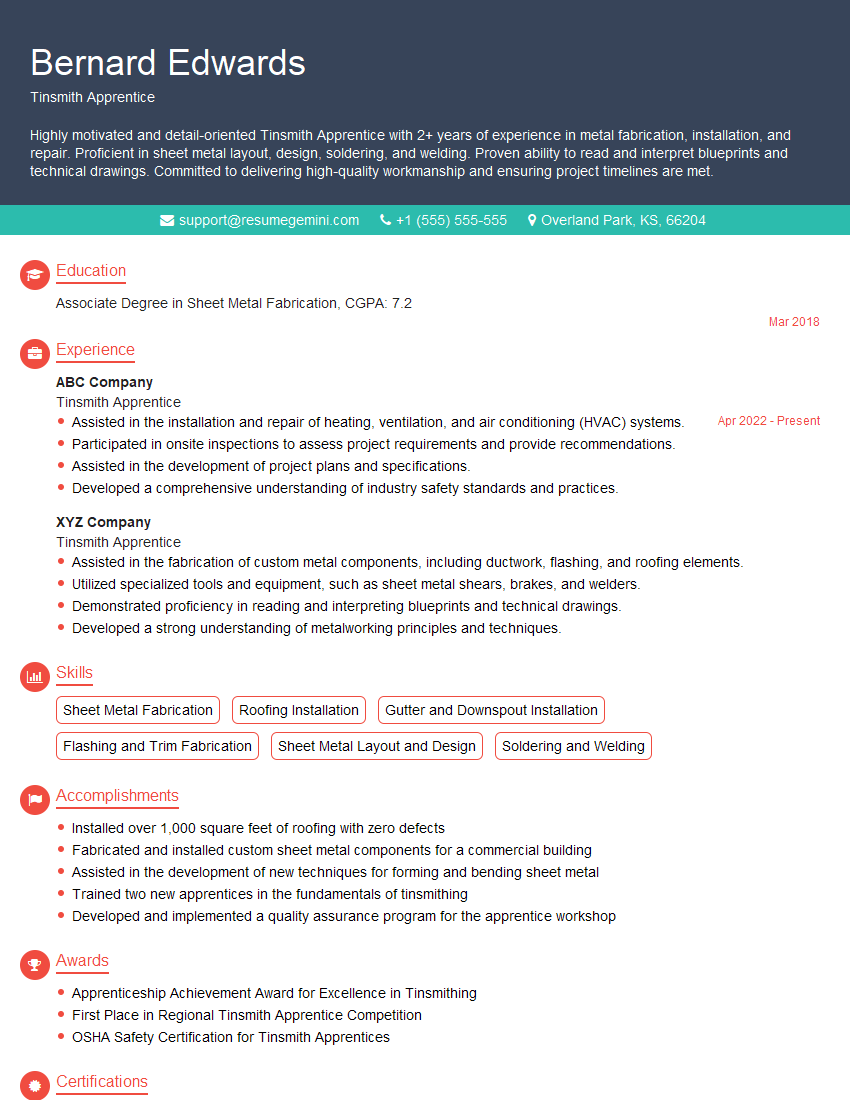

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tinsmith Apprentice

1. Describe the process of creating a simple ductwork system.

The process of creating a simple ductwork system involves several steps:

- Design and layout: Determine the size, shape, and layout of the ducts to meet the airflow requirements of the space.

- Material selection: Choose the appropriate duct material, such as galvanized steel, aluminum, or fiberglass, based on the application and environmental conditions.

- Fabrication: Cut and shape the duct parts using specialized tools and machines.

- Assembly: Join the duct sections together using rivets, screws, or adhesive.

- Installation: Mount the ductwork in the designated location, ensuring proper support and alignment.

- Sealing and testing: Seal the joints and test the system for leaks to ensure airtightness.

2. Explain the different types of soldering techniques used in tinsmithing.

Soft soldering:

- Used for joining low-melting-point metals like tin, lead, and zinc.

- Involves using a flux to clean and prepare the metal surfaces before soldering.

- Produces a relatively weak but malleable joint.

Hard soldering:

- Used for joining high-melting-point metals like copper, brass, and bronze.

- Requires a higher temperature and a more specialized flux.

- Produces a stronger and more durable joint.

3. How do you determine the correct size of ductwork for a specific application?

To determine the correct size of ductwork, it is necessary to consider several factors:

- Airflow requirements: Calculate the volume of air that needs to be moved through the system.

- Friction loss: Account for the resistance to airflow caused by the duct walls and fittings.

- Velocity: Ensure that the air velocity is within acceptable limits to prevent noise and energy loss.

- Pressure drop: Calculate the pressure drop through the ductwork to ensure sufficient airflow.

- Duct material and shape: Consider the properties and dimensions of the duct material used.

4. Describe the safety precautions that must be taken when working with sheet metal.

When working with sheet metal, it is crucial to follow safety precautions to prevent injuries:

- Wear protective gear: Use gloves, safety glasses, and appropriate clothing to protect against sharp edges and flying debris.

- Use sharp tools: Maintain sharp tools to minimize force and prevent slipping.

- Secure workpieces: Clamp or hold sheet metal securely before cutting or shaping to prevent accidents.

- Avoid pinch points: Be aware of potential pinch points between the sheet metal and tools or machinery.

- Handle heavy loads carefully: Use proper lifting techniques and seek assistance for heavy materials.

5. Explain the importance of proper ventilation in ductwork systems.

Proper ventilation in ductwork systems is essential for several reasons:

- Air quality: Ventilation provides fresh air and removes contaminants, ensuring healthy indoor air quality.

- Moisture control: Ventilation helps control moisture levels, preventing condensation and mold growth within the ductwork.

- Energy efficiency: Proper ventilation reduces the load on HVAC systems, improving energy efficiency.

- Safety: Ventilation removes harmful gases, such as carbon monoxide, which can accumulate in ductwork.

6. How do you troubleshoot and repair a leaky duct?

To troubleshoot and repair a leaky duct:

- Locate the leak: Use a smoke pencil or soapy water to identify the source of the leak.

- Assess the damage: Determine the extent of the leak and whether it requires patching or replacement.

- Prepare the area: Clean the area around the leak and remove any obstacles.

- Patch or replace the duct: If the leak is small, apply a patch using duct tape or sealant. For larger leaks, the damaged section may need to be replaced.

- Seal the joints: Ensure all joints and connections are properly sealed to prevent future leaks.

7. Describe the different types of sheet metal forming techniques.

Sheet metal forming involves various techniques to shape and manipulate metal sheets:

- Bending: Using a brake or press to create angles and curves in the sheet metal.

- Rolling: Passing the sheet metal through rollers to create cylindrical or conical shapes.

- Flanging: Creating a raised edge or lip around the perimeter of the sheet metal.

- Stretching: Expanding the sheet metal to create a larger surface area.

- Spinning: Using a lathe to rotate the sheet metal while applying force to create complex shapes.

8. Explain the process of fabricating a custom sheet metal part.

To fabricate a custom sheet metal part:

- Design and layout: Create a design and layout for the part using CAD software or manual drafting.

- Material selection: Choose the appropriate sheet metal material based on the part’s requirements.

- Cutting: Use shears, laser cutters, or water jets to cut the sheet metal to the desired shape.

- Bending and forming: Utilize bending brakes, rollers, or other forming tools to shape the part according to the design.

- Assembly: Join the individual parts together using rivets, screws, or welding.

- Finishing: Perform any necessary finishing operations, such as painting or powder coating.

9. Describe the different types of sheet metal finishes and their applications.

Sheet metal finishes provide protection and enhance the appearance of the material:

- Galvanized: Zinc coating for corrosion resistance, commonly used in roofing and outdoor applications.

- Painted: Applied coatings for color, protection, and aesthetics, often used in interior and architectural applications.

- Powder coated: Electrostatically applied powder that provides a durable and resistant finish, commonly used in industrial and automotive applications.

- Anodized: Electrolytic process that creates a protective and decorative oxide layer on aluminum, used in architectural and electronic applications.

- Electroplated: Deposition of a metal coating for corrosion resistance and improved appearance, often used in plumbing and automotive parts.

10. Explain the importance of quality control in sheet metal fabrication.

Quality control is crucial in sheet metal fabrication to ensure:

- Dimensional accuracy: Verifying that the fabricated parts meet the specified dimensions.

- Material quality: Inspecting the sheet metal material for defects and ensuring it meets the project requirements.

- Structural integrity: Testing the fabricated parts to ensure they can withstand the intended loads and stresses.

- Surface finish: Checking that the finished products meet the specified aesthetic and functional requirements.

- Compliance with standards: Adhering to industry standards and regulations to ensure product safety and reliability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tinsmith Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tinsmith Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tinsmith Apprentice assists skilled tinsmiths in the fabrication and installation of a wide range of metal products, primarily made from sheet metal. Their duties encompass a variety of tasks that contribute to the successful completion of projects within the construction, manufacturing, or automotive industries.

1. Assisting in Sheet Metal Fabrication

Apprentices play a crucial role in supporting the fabrication of sheet metal components. They assist with cutting, shaping, and assembling metal sheets using specialized tools and equipment. They may also engage in welding, soldering, or riveting to join metal pieces together.

- Cutting metal sheets to precise dimensions using shears, nibblers, or plasma cutters

- Bending and forming metal sheets into desired shapes using brake presses, rollers, or hand tools

- Assembling metal components using adhesives, screws, bolts, or rivets

2. Assisting in Installation

Apprentices assist in the installation of fabricated metal products. They may work on rooftops, in buildings, or on vehicles. They help position and secure metal components, ensuring proper alignment and functionality.

- Installing metal roofing, siding, or gutters

- Fitting and connecting metal ducts, pipes, or enclosures

- Attaching metal trim, flashing, or accessories

3. Material Handling and Inventory Management

Apprentices assist with material handling and inventory management. They may be responsible for unloading and storing metal sheets, tools, and other materials. They may also assist in organizing and maintaining an inventory of available materials.

- Unloading and storing metal sheets, tools, and materials

- Organizing and maintaining an inventory of materials

- Retrieving materials for fabrication and installation

4. General Maintenance and Cleanup

Apprentices are expected to assist with general maintenance and cleanup of the work area. They may clean tools and equipment, sweep up debris, and dispose of waste materials.

- Cleaning tools and equipment

- Sweeping up debris and waste materials

- Maintaining a clean and organized work environment

Interview Tips

Preparing for an interview can significantly boost your chances of making a positive impression on the hiring manager. Here are some tips to help you ace your interview for a Tinsmith Apprentice position:

1. Research the Company and the Position

Before the interview, take the time to thoroughly research the company and the specific position you are applying for. Visit the company website, read industry news articles, and check out their social media pages. This will give you a good understanding of their culture, values, and the nature of the work they do. Knowing about the company and the position will allow you to tailor your answers to their needs and show that you are genuinely interested in the opportunity.

- Visit the company website and read about their history, mission, and products/services

- Read industry news articles to stay up-to-date on the latest trends and developments

- Check out the company’s social media pages to get a sense of their culture and values

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked in Tinsmith Apprentice interviews. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely. Some common interview questions for Tinsmith Apprentices include:

- Tell me about your experience working with sheet metal

- Describe a time when you had to overcome a challenge on a project

- Why are you interested in working as a Tinsmith Apprentice?

3. Be Prepared to Show Your Portfolio

If you have any relevant experience or skills, such as working with sheet metal, welding, or soldering, be sure to bring a portfolio to the interview. This will give the hiring manager a chance to see your work and assess your abilities firsthand.

- Bring a portfolio of your work, such as photos or sketches of projects you have completed

- Include examples of your welding, soldering, or other relevant skills

- Be prepared to discuss your portfolio and explain the techniques you used

4. Dress Professionally and Arrive on Time

First impressions matter, so be sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace. Also, arrive on time for your interview. Punctuality shows that you are respectful of the hiring manager’s time and that you are serious about the opportunity.

- Wear clean, pressed clothes that are appropriate for the workplace

- Arrive on time for your interview

- Be polite and respectful to everyone you meet

Next Step:

Now that you’re armed with the knowledge of Tinsmith Apprentice interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tinsmith Apprentice positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini