Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tinner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tinner so you can tailor your answers to impress potential employers.

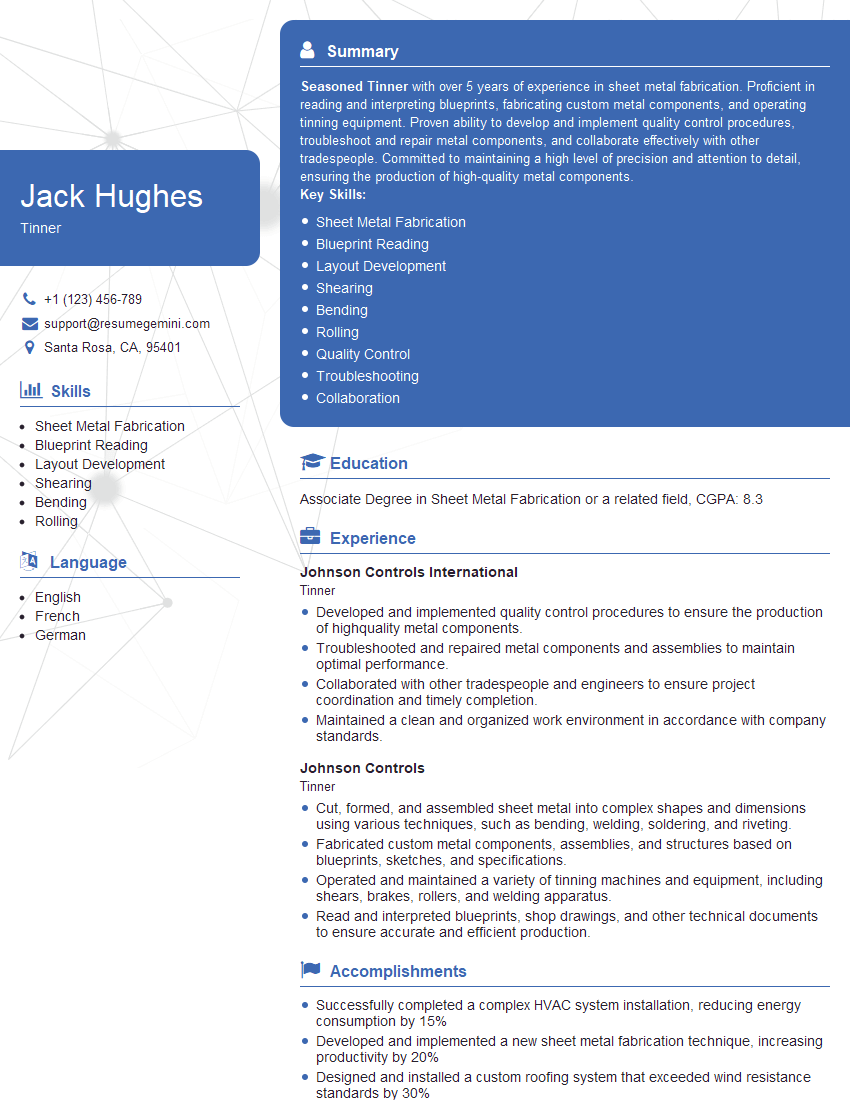

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tinner

1. Explain the process of applying a clear finish to a wood surface.

- Prepare the wood surface by sanding it smooth and removing any dust or debris.

- Apply a thin coat of clear finish to the wood surface using a brush, roller, or spray gun.

- Allow the first coat of finish to dry completely before applying a second coat.

- Sand the second coat of finish lightly with fine-grit sandpaper to remove any imperfections.

- Apply a third coat of finish to the wood surface and allow it to dry completely.

- Buff the finished surface with a soft cloth to remove any excess finish and bring out the shine.

2. What are the different types of tinning compounds available, and how do they differ in their properties and applications?

Fluxes

- Rosin: A natural resin that is commonly used for soldering copper and copper alloys.

- Acid: A corrosive flux that is used for soldering metals that are difficult to solder, such as aluminum and stainless steel.

- Water-soluble: A flux that is easy to clean up and is used for soldering electronic components.

Solders

- Lead-based: A traditional solder that is strong and easy to use, but it is also toxic.

- Lead-free: A solder that is safer to use than lead-based solder, but it is not as strong.

- Silver-bearing: A solder that is used for soldering high-temperature applications.

3. Describe the safety precautions that should be taken when working with tinning compounds.

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a respirator.

- Work in a well-ventilated area.

- Do not smoke or eat while working with tinning compounds.

- Keep tinning compounds away from children and pets.

- Dispose of tinning compounds properly according to local regulations.

4. What are the common problems that can occur when applying a clear finish to a wood surface, and how can they be prevented?

- Runs and sags: Caused by applying too much finish or applying it too quickly. Can be prevented by applying thin, even coats and allowing each coat to dry completely before applying the next.

- Brush marks: Caused by using a brush that is too stiff or by applying the finish too quickly. Can be prevented by using a soft brush and applying the finish slowly and evenly.

- Bubbles: Caused by trapped air in the finish. Can be prevented by stirring the finish thoroughly before applying it and by avoiding applying it in thick coats.

- Fisheyes: Caused by contamination of the finish with dirt or oil. Can be prevented by cleaning the wood surface thoroughly before applying the finish and by using clean brushes and rollers.

5. How do you determine the proper consistency of a tinning compound?

- For fluxes: The flux should be thin enough to flow easily, but not so thin that it runs off the metal surface.

- For solders: The solder should be solid at room temperature, but it should melt easily when heated.

6. What are the different methods of applying tinning compounds?

- Brush: A brush is used to apply tinning compounds to small areas or to touch up areas that have been missed.

- Roller: A roller is used to apply tinning compounds to large areas.

- Spray gun: A spray gun is used to apply tinning compounds to large areas or to areas that are difficult to reach with a brush or roller.

7. How do you test the quality of a tinned surface?

- Visual inspection: The tinned surface should be smooth and shiny, with no visible defects.

- Solderability test: A solderability test is used to determine how well the tinned surface can be soldered.

8. What are the different types of tinning equipment available?

- Soldering irons: Soldering irons are used to melt solder and apply it to metal surfaces.

- Soldering guns: Soldering guns are used to melt solder and apply it to metal surfaces. They are more powerful than soldering irons and can be used to solder larger areas.

- Tinning baths: Tinning baths are used to tin large metal surfaces. The metal is dipped into the bath and the solder melts and adheres to the metal surface.

9. How do you maintain tinning equipment?

- Soldering irons: The tip of the soldering iron should be kept clean and free of oxidation. The iron should be stored in a cool, dry place.

- Soldering guns: The soldering gun should be cleaned regularly according to the manufacturer’s instructions. The gun should be stored in a cool, dry place.

- Tinning baths: The tinning bath should be kept clean and free of contamination. The bath should be stored in a cool, dry place.

10. What are the different applications of tinning?

- Soldering: Tinning is used to prepare metal surfaces for soldering. The tinned surface provides a good surface for the solder to adhere to.

- Corrosion protection: Tinning can be used to protect metal surfaces from corrosion. The tinned surface acts as a barrier between the metal and the corrosive environment.

- Electrical conductivity: Tinning can be used to improve the electrical conductivity of metal surfaces. The tinned surface provides a low-resistance path for electrical current to flow.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tinner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tinner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tinner is responsible for working with thin metal sheets, cutting them to specifications, and forming them into various shapes. They must have excellent attention to detail and be able to follow instructions precisely. Some of the key job responsibilities of a Tinner include:

1. Cutting and Shaping Metal Sheets

Tinners use a variety of tools to cut and shape metal sheets, including shears, punches, and dies. They must be able to accurately measure and mark the metal, and then use the appropriate tools to cut and shape it to the desired specifications.

2. Assembling and Installing Tin Products

Tinners also assemble and install tin products, such as ductwork, gutters, and roofing. They must be able to read blueprints and follow instructions, and they must have the skills to safely and securely install the products.

3. Maintaining and Repairing Tin Products

Tinners also maintain and repair tin products. They must be able to identify and fix leaks, cracks, and other damage. They must also be able to clean and repaint tin products to keep them looking their best.

4. Working with Other Tradespeople

Tinners often work with other tradespeople, such as carpenters, plumbers, and electricians. They must be able to communicate effectively with these other tradespeople and work together to complete projects on time and within budget.

Interview Tips

There are a few key things you can do to prepare for a job interview and increase your chances of getting the job.

1. Research the Company and the Position

Before you go on an interview, it’s important to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you answer questions about your qualifications and experience.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” It’s a good idea to practice answering these questions in advance so that you can deliver your answers with confidence.

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

4. Arrive on Time

Punctuality is important, so make sure you arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the job.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tinner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.