Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Atomic Process Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

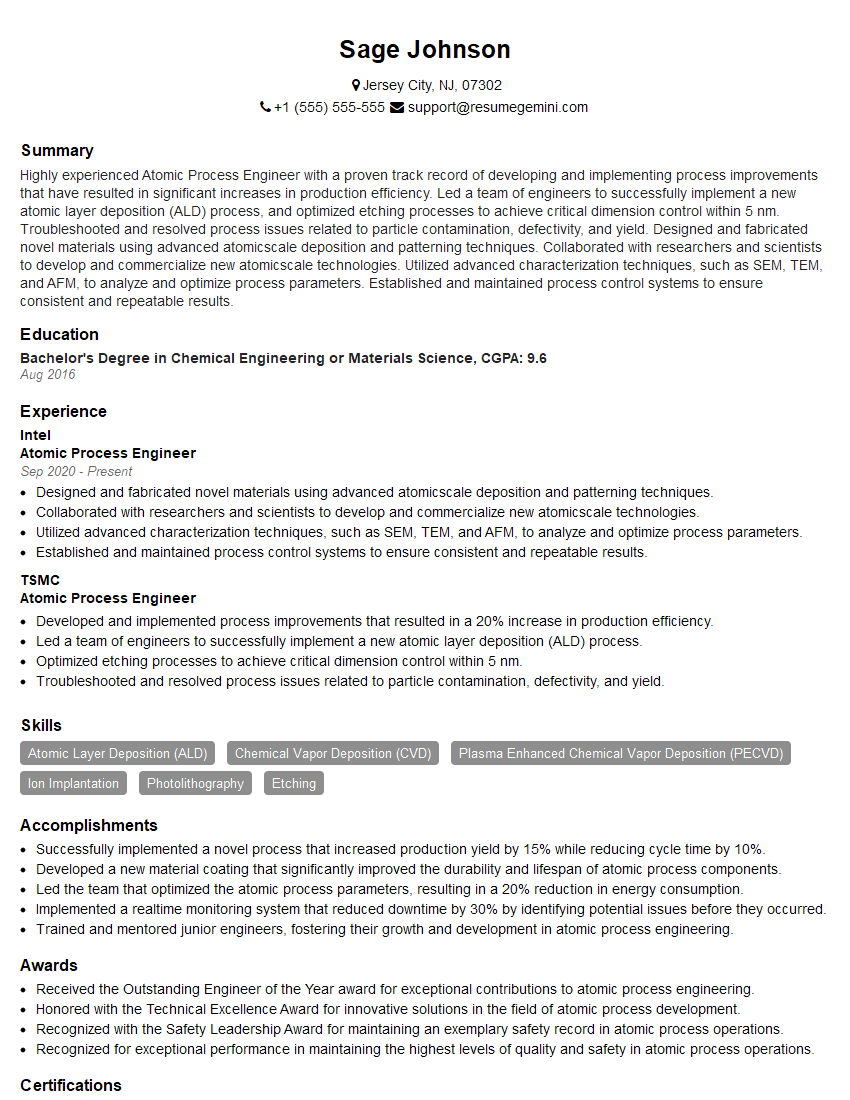

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Atomic Process Engineer

1. Explain the concept of etching in atomic layer deposition (ALD)?

Etching in atomic layer deposition (ALD) is a process used to remove material from a substrate surface in a controlled manner. It is typically used to create patterns or features in the material, such as trenches or vias.

- In ALD, etching is achieved by exposing the substrate to a reactive gas or plasma that selectively removes the desired material.

- The process is self-limiting, which means that the etching stops once the desired amount of material has been removed.

- ALD etching is conformal, which means that it can etch into complex geometries without losing selectivity.

2. Describe the different types of CVD reactors and their applications?

High-pressure CVD (HPCVD)

- Uses high pressures (1-10 atm) to increase the deposition rate.

- Typically used for depositing thick films (e.g., silicon nitride, polysilicon).

Low-pressure CVD (LPCVD)

- Uses low pressures (0.1-1 atm) to improve film quality.

- Typically used for depositing thin films (e.g., silicon dioxide, silicon carbide).

Plasma-enhanced CVD (PECVD)

- Uses a plasma to generate reactive species that enhance the deposition process.

- Typically used for depositing films with high electrical conductivity (e.g., metal nitrides, metal oxides).

Metal-organic CVD (MOCVD)

- Uses metal-organic precursors that decompose to form the desired film.

- Typically used for depositing complex materials (e.g., III-V semiconductors, high-k dielectrics).

3. What are the key factors that affect the growth rate in ALD?

The growth rate in ALD is affected by a number of factors, including:

- Substrate temperature

- Precursor concentration

- Purge time

- Reactor pressure

- Substrate orientation

The growth rate can be controlled by adjusting these factors to achieve the desired film properties.

4. Explain the difference between thermal ALD and plasma-enhanced ALD?

- Thermal ALD uses thermal energy to activate the precursor molecules, while plasma-enhanced ALD uses a plasma to generate reactive species that enhance the deposition process.

- Thermal ALD typically operates at lower temperatures than plasma-enhanced ALD, and is therefore more suitable for depositing films on delicate substrates.

- Plasma-enhanced ALD can achieve higher deposition rates than thermal ALD, but can also damage the substrate if the plasma is not properly controlled.

5. What are the applications of ALD in the semiconductor industry?

- Deposition of high-k dielectrics (e.g., hafnium oxide, aluminum oxide)

- Deposition of metal films (e.g., titanium nitride, copper)

- Deposition of protective coatings (e.g., silicon nitride, silicon oxide)

- Patterning of materials (e.g., etching of silicon, deposition of metal lines)

6. What are the challenges in scaling ALD for high-volume manufacturing?

- Low deposition rates

- High cost of precursors

- Complexity of ALD processes

- Need for specialized equipment

7. What are the emerging trends in ALD?

- Development of new precursors and processes to improve deposition rates and film quality

- Integration of ALD with other deposition techniques to create complex structures

- Use of ALD for 3D printing and other additive manufacturing applications

8. Describe the process of atomic layer etching (ALE)?

Atomic layer etching (ALE) is a process used to selectively remove material from a substrate surface in a controlled manner. It is typically used to create patterns or features in the material, such as trenches or vias.

- In ALE, etching is achieved by exposing the substrate to a reactive gas or plasma that selectively reacts with the desired material.

- The process is self-limiting, which means that the etching stops once the desired amount of material has been removed.

- ALE etching is conformal, which means that it can etch into complex geometries without losing selectivity.

9. What are the advantages of ALE over traditional etching techniques?

- ALE is more selective than traditional etching techniques, which can lead to improved pattern fidelity and reduced damage to the substrate.

- ALE is conformal, which means that it can etch into complex geometries without losing selectivity.

- ALE is self-limiting, which means that the etching stops once the desired amount of material has been removed.

10. What are the applications of ALE in the semiconductor industry?

- Patterning of materials (e.g., etching of silicon, deposition of metal lines)

- Removal of unwanted material (e.g., removal of photoresist, cleaning of substrates)

- Creation of 3D structures (e.g., etching of trenches, vias, and pillars)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Atomic Process Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Atomic Process Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Atomic Process Engineers play a significant role in the semiconductor industry, contributing to the development and advancement of cutting-edge technologies.

1. Process Development and Implementation

Involves researching, developing, and refining atomic layer deposition (ALD) and atomic layer etching (ALE) processes for various materials used in semiconductor fabrication.

- Optimizing process parameters to achieve desired film properties, such as thickness, uniformity, and conformality.

- Developing new process recipes and exploring innovative techniques to enhance process efficiency and material quality.

2. Equipment Maintenance and Troubleshooting

Ensures the proper functioning and maintenance of ALD and ALE equipment to maximize uptime and minimize downtime.

- Performing routine maintenance tasks, such as chamber cleaning, precursor replacement, and system diagnostics.

- Troubleshooting equipment issues, identifying root causes, and implementing corrective actions to restore optimal performance.

3. Process Characterization and Analysis

Conducts thorough characterization of deposited films using advanced analytical techniques to evaluate their properties.

- Utilizing X-ray diffraction (XRD), scanning electron microscopy (SEM), and transmission electron microscopy (TEM) for film thickness, composition, and microstructure analysis.

- Interpreting data and providing insights into the relationship between process parameters and film characteristics.

4. Collaboration and Communication

Collaborates closely with cross-functional teams, including engineers, scientists, and technicians, to support overall process development and manufacturing goals.

- Communicating process knowledge, findings, and recommendations to stakeholders within the organization.

- Participating in meetings, presentations, and technical discussions to share expertise and contribute to decision-making.

Interview Tips

To ace your interview for an Atomic Process Engineer position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and culture. Research the latest trends and advancements in the semiconductor industry.

2. Showcase Your Technical Expertise

Highlight your knowledge of ALD and ALE processes, equipment troubleshooting, and film characterization techniques. Emphasize your understanding of the underlying principles and your ability to apply them in practical scenarios.

3. Prepare Examples of Successful Projects

Describe projects where you have successfully optimized processes, solved equipment issues, or characterized materials. Quantify your results and explain how your contributions impacted the team or organization.

4. Demonstrate Your Communication Skills

Atomic Process Engineers need to be able to communicate clearly and effectively with colleagues, supervisors, and customers. Prepare examples of your written and verbal communication skills, such as presentations, reports, or technical discussions.

5. Ask Informed Questions

Ask thoughtful questions during the interview to show your interest, engagement, and attention to detail. Inquire about the current projects, challenges, and opportunities within the team or organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Atomic Process Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!