Are you gearing up for a career in Steel Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Steel Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

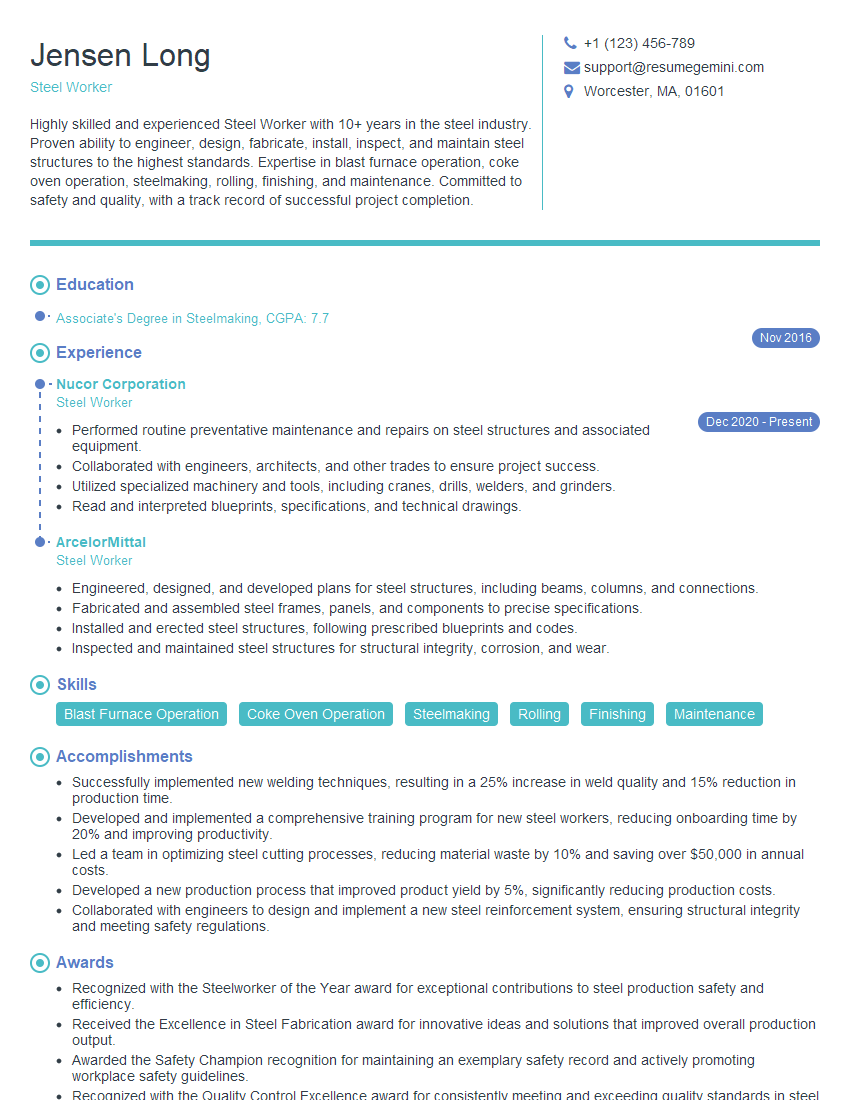

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Worker

1. Describe the different types of steel used in construction and their properties?

In construction, various types of steel are employed, each with unique properties:

- Carbon Steel: Most common type, offers a balance of strength, durability, and cost.

- Alloy Steel: Enhanced with elements like chromium, nickel, and molybdenum for improved strength, hardness, and corrosion resistance.

- Stainless Steel: Highly resistant to corrosion, rust, and stains, making it ideal for applications requiring hygiene and aesthetics.

- Tool Steel: Specially formulated for use in cutting and shaping tools due to its exceptional hardness and wear resistance.

- High-Strength Steel: Boasts a high strength-to-weight ratio, allowing for lightweight structures with enhanced load-bearing capacity.

2. What are the key safety precautions that must be followed when working with steel?

Personal Protective Equipment (PPE)

- Hard hats, safety glasses, and gloves to protect against falling objects, sparks, and sharp edges.

Safe Handling Techniques

- Proper lifting and carrying techniques to prevent injuries.

- Using appropriate tools and equipment for cutting, welding, and shaping steel.

Work Environment

- Maintaining a clean and organized work area.

- Ensuring proper ventilation to remove dust, fumes, and gases.

3. How do you ensure the quality of steel fabrication in your work?

Quality assurance in steel fabrication involves several measures:

- Material Inspection: Verifying the quality and compliance of incoming steel materials.

- Fabrication Process Control: Adhering to established procedures and following industry standards.

- Non-Destructive Testing (NDT): Employing techniques like ultrasonic testing and radiography to detect defects.

- Visual Inspections: Regularly examining welds, joints, and overall finish for any imperfections.

- Documentation and Traceability: Maintaining records of materials used, processes followed, and inspections conducted.

4. What are the common methods for joining steel components?

The most widely used methods for joining steel components include:

- Welding: Fusing steel pieces together using heat and pressure. Various techniques include arc welding, MIG welding, and TIG welding.

- Bolting: Using high-strength bolts to mechanically fasten steel components.

- Riveting: Inserting a rivet into pre-drilled holes to create a permanent joint.

- Structural Adhesives: Employing specialized adhesives to bond steel surfaces.

5. How do you handle the challenges of working with large and heavy steel structures?

Managing large and heavy steel structures requires careful planning and execution:

- Planning and Logistics: Coordinating transportation, lifting equipment, and manpower.

- Structural Analysis: Ensuring the design can withstand loads and stresses.

- Material Handling: Employing cranes, hoists, and other specialized equipment for lifting and positioning.

- Safety Precautions: Implementing rigorous safety measures to mitigate risks during handling and installation.

6. What types of tools and equipment are essential for steel fabrication?

Essential tools and equipment for steel fabrication include:

- Welding Equipment: Arc welders, MIG welders, and TIG welders.

- Cutting Equipment: Oxy-fuel torches, plasma cutters, and water jet cutters.

- Shaping Equipment: Bending brakes, rolling machines, and press brakes.

- Lifting Equipment: Cranes, hoists, and forklifts.

- Inspection Equipment: Non-destructive testing equipment, measuring tools, and quality control devices.

7. How do you stay up-to-date with industry best practices and new technologies in steel fabrication?

To stay current in the field, I engage in the following practices:

- Attending Industry Events: Participating in conferences, workshops, and trade shows.

- Reading Technical Publications: Subscribing to industry journals and magazines.

- Online Research: Exploring industry websites, forums, and technical articles.

- Training and Certification: Pursuing professional development opportunities and obtaining relevant certifications.

8. How do you ensure that fabricated steel components meet project specifications?

To meet project specifications, I follow these quality control measures:

- Material Verification: Verifying the composition and properties of steel materials against requirements.

- Fabrication Process Control: Adhering to established procedures and using calibrated equipment.

- Inspection and Testing: Conducting regular inspections and tests to assess compliance with specifications.

- Documentation and Traceability: Maintaining records of materials, processes, and inspections for traceability.

9. What is your approach to working in a team environment on steel fabrication projects?

In team environments, I approach projects with the following mindset:

- Effective Communication: Actively listening, sharing information, and coordinating with team members.

- Collaboration: Working together to solve problems, share expertise, and support each other.

- Respect for Roles: Recognizing and valuing the contributions of different team members.

- Continuous Improvement: Sharing ideas, identifying areas for improvement, and implementing changes to enhance team performance.

10. How do you handle situations where there are conflicting priorities or deadlines?

When faced with conflicting priorities or deadlines, I prioritize my actions based on the following steps:

- Assess the Situation: Evaluating the urgency and importance of each task.

- Prioritize and Delegate: Identifying the most critical tasks and delegating others to free up my capacity.

- Communicate and Negotiate: Discussing the situation with stakeholders and negotiating adjustments to deadlines when necessary.

- Time Management: Utilizing techniques to optimize time usage and increase productivity.

- Flexibility and Adaptation: Being open to adjusting my schedule and adapting to unforeseen changes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Workers are responsible for the fabrication, installation, and assembly of structural steel components.

1. Fabrication

Develop and interpret plans and drawings to determine specifications for the fabrication of steel components.

- Operate and maintain fabrication machinery, such as shears, brakes, welders, and cranes.

- Cut, shape, and weld steel components to meet specifications.

2. Installation

Prepare and lay out the foundation for steel structures.

- Erect and align steel components using cranes and other equipment.

- Bolt or weld steel components together to form the desired structure.

3. Assembly

Assemble and fit steel components to form complete structures, such as bridges, buildings, and towers.

- Read and interpret blueprints and other technical documents.

- Use precision tools and equipment to assemble components.

4. Maintenance

Inspect and maintain steel structures to ensure their integrity and safety.

- Identify and repair any damage or defects.

- Perform regular maintenance tasks, such as painting, cleaning, and lubrication.

Interview Tips

Preparing for a Steel Worker interview requires research, practice, and confidence. Here are some tips to help you ace the interview.

1. Research the Company and Industry

Research the company’s history, values, and recent projects. This will demonstrate your interest and knowledge of the industry.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about current trends.

2. Practice Your Answers to Common Interview Questions

Anticipate typical interview questions and prepare thoughtful responses. Practice delivering your answers clearly and concisely.

- Tell me about your experience in steel fabrication and installation. Example Outline: – Introduction: Describe your overall experience in the field. – Fabrication: Highlight your skills in operating and maintaining fabrication machinery, such as shears and welders. – Installation: Discuss your ability to prepare foundations, erect steel components, and ensure proper alignment.

- How do you ensure the safety and quality of your work? Example Outline: – Introduction: State your commitment to safety and quality. – Safety: Describe specific safety measures you follow, such as wearing appropriate PPE and using proper lifting techniques. – Quality: Explain your attention to detail and ability to meet or exceed industry standards.

3. Highlight Your Relevant Skills and Experience

Emphasize the skills and experience that are most relevant to the job requirements. Provide specific examples to demonstrate your abilities.

- Use action verbs and quantify your accomplishments whenever possible. Example: “Installed over 500 tons of structural steel on a high-rise building within a tight deadline.”

- Be prepared to discuss your proficiency in welding, cutting, rigging, and other essential techniques.

4. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the job and your commitment to the industry. Maintain a professional demeanor throughout the interview.

- Dress appropriately and arrive on time for the interview.

- Make eye contact with the interviewer and speak clearly and confidently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Steel Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.