Feeling lost in a sea of interview questions? Landed that dream interview for Structural Steel Fitter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Structural Steel Fitter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

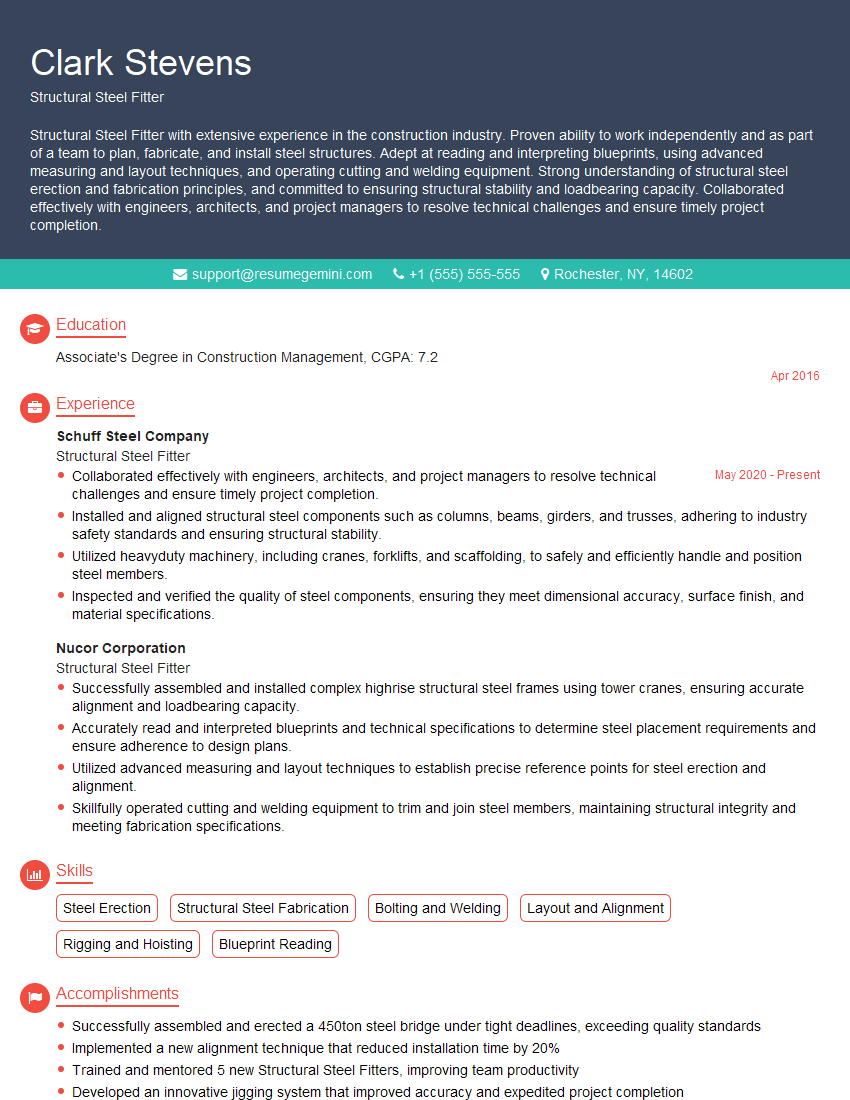

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Structural Steel Fitter

1. Explain the different types of structural steel and their properties?

- Carbon Steel: Most commonly used, high strength and hardness, good weldability.

- Alloy Steel: Added alloying elements (e.g., chromium, nickel) for enhanced strength, toughness, and corrosion resistance.

- Stainless Steel: Excellent corrosion resistance, high strength, and durability.

- Weathering Steel: Forms a protective oxide layer that resists atmospheric corrosion.

- High-Strength Low-Alloy (HSLA) Steel: Improved strength and toughness compared to carbon steel, used for lighter structures.

2. Describe the various methods of connecting structural steel members?

- Bolting: Using high-strength bolts to connect members, providing a strong and reversible joint.

- Welding: Fusing members together using heat, creating a permanent and load-bearing connection.

- Riveting: Inserting rivets into holes to create a permanent joint, typically used in older structures.

- Pin Connections: Using pins to connect members, allowing for rotation and axial movement.

- Clip Angles: Small angles used to connect non-coplanar members, providing shear and moment resistance.

3. How do you ensure the accuracy and safety of your work when fitting structural steel?

- Thorough Planning: Reviewing drawings, calculating loads, and determining the necessary materials and methods.

- Precision Measurements: Using measuring tools (e.g., tape measures, levels) to accurately mark and cut materials.

- Proper Alignment: Verifying that members are aligned correctly before connecting them.

- Secure Connections: Ensuring that bolts, welds, or rivets are properly tightened and secured.

- Safety Protocols: Adhering to all safety regulations, using appropriate protective equipment, and maintaining a clean and organized work area.

4. Explain the importance of proper handling and storage of structural steel?

- Preventing Damage: Improper handling can lead to bending, warping, or damage to the steel, compromising its structural integrity.

- Safety Considerations: Heavy steel sections require proper lifting and rigging techniques to avoid accidents.

- Corrosion Prevention: Storing steel in dry and well-ventilated areas minimizes the risk of corrosion.

- Space Optimization: Proper organization and storage techniques allow for efficient use of storage space.

- Compliance with Regulations: Following industry standards and regulations ensures safe and responsible handling and storage practices.

5. Describe the different types of welding processes used in structural steel fabrication?

- Shielded Metal Arc Welding (SMAW): Using a consumable electrode covered with flux, creating a strong and economical weld.

- Gas Metal Arc Welding (GMAW): Using a continuous wire electrode and inert gas for shielding, providing high productivity and versatility.

- Gas Tungsten Arc Welding (GTAW): Using a non-consumable tungsten electrode and inert gas for shielding, delivering high-quality welds.

- Submerged Arc Welding (SAW): Using a continuous wire electrode and granulated flux to shield the weld, achieving high deposition rates.

- Electroslag Welding (ESW): Using consumable electrodes and molten slag for a high-quality and efficient welding process.

6. Explain the different types of non-destructive testing (NDT) methods used for structural steel?

- Ultrasonic Testing (UT): Using high-frequency sound waves to detect internal defects and measure material thickness.

- Radiographic Testing (RT): Using X-rays or gamma rays to create an image of the material, revealing internal defects.

- Magnetic Particle Inspection (MPI): Using magnetic particles to detect surface-breaking cracks and discontinuities.

- Dye Penetrant Inspection (DPI): Using a penetrant dye to reveal surface defects and cracks.

- Visual Inspection (VI): Using visual aids (e.g., mirrors, magnifying glasses) to examine the material for surface defects.

7. How do you stay updated on the latest advancements and best practices in structural steel fitting?

- Industry Publications: Reading trade journals, newsletters, and technical articles.

- Conferences and Seminars: Attending industry events to learn from experts and share knowledge.

- Online Learning Platforms: Taking online courses and webinars to enhance skills and gain certifications.

- Networking with Professionals: Connecting with other structural steel fitters and industry professionals to exchange ideas.

- Company Training Programs: Participating in in-house training programs to stay updated on company-specific practices and technologies.

8. Describe the role of structural steel fitters in the construction process?

- Interpreting Drawings: Reading and understanding structural drawings to determine the dimensions, materials, and connections.

- Material Preparation: Cutting, shaping, and preparing steel members according to specifications.

- Assembly and Erection: Fitting and connecting steel members to form the structural framework of buildings, bridges, and other structures.

- Welding and Bolting: Joining steel members using welding or bolting techniques to create secure and load-bearing connections.

- Quality Assurance: Ensuring the accuracy, safety, and quality of the fabricated and erected steel structure.

9. How do you prioritize and manage multiple projects simultaneously?

- Effective Planning: Breaking down projects into smaller tasks and setting realistic timelines.

- Communication and Coordination: Collaborating with team members and supervisors to ensure timely completion of tasks.

- Resource Allocation: Optimizing the allocation of materials, equipment, and personnel to avoid bottlenecks.

- Flexibility and Adaptability: Adjusting plans and priorities to respond to changes in project scope or unexpected events.

- Progress Tracking: Monitoring progress and identifying potential delays or issues to implement corrective actions.

10. What safety measures do you take when working with structural steel?

- Personal Protective Equipment (PPE): Wearing proper PPE such as hard hats, safety glasses, gloves, and appropriate clothing.

- Hazard Identification and Avoidance: Identifying and mitigating potential hazards such as electrical hazards, falling objects, and confined spaces.

- Proper Lifting and Rigging: Using appropriate lifting and rigging equipment and techniques to avoid injuries.

- Safe Work Environment: Maintaining a clean and organized work area, eliminating tripping hazards, and ensuring adequate ventilation.

- Emergency Preparedness: Knowing and following emergency protocols, including evacuation procedures and first aid administration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Structural Steel Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Structural Steel Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Structural Steel Fitters play a pivotal role in the construction industry, ensuring the precise assembly of steel structures. Their responsibilities encompass a wide range of tasks:

1. Steel Structure Assembly

Meticulously assemble steel structures according to blueprints and specifications, utilizing various tools and equipment, including cranes, welding machines, and power tools.

- Interpret blueprints and work orders to understand project requirements.

- Prepare and align steel components, ensuring proper fit and alignment.

- Secure components together using welding, bolting, or riveting techniques.

2. Structural Inspection and Maintenance

Conduct regular inspections of steel structures to identify potential defects or damage, ensuring the safety and integrity of the structure.

- Perform visual inspections to detect cracks, corrosion, or deformation.

- Utilize non-destructive testing methods, such as ultrasonic or magnetic particle inspection, to assess structural integrity.

- Implement repair or maintenance procedures as necessary to address identified issues.

3. Collaboration and Communication

Collaborate effectively with engineers, architects, and other construction professionals to ensure project success.

- Attend project planning meetings to discuss design and installation details.

- Communicate with supervisors and colleagues to keep them informed of progress and any challenges encountered.

- Work as part of a team to complete projects on time and within budget.

4. Safety Compliance

Adhere to all safety regulations and guidelines to ensure a safe work environment for themselves and others.

- Wear appropriate personal protective equipment, including hard hats, safety glasses, and gloves.

- Follow established safety protocols and procedures.

- Report any potential hazards or safety concerns to supervisors immediately.

Interview Tips

To ace your Structural Steel Fitter interview, it is crucial to prepare thoroughly and demonstrate your skills and knowledge. Here are some tips to enhance your chances of success:

1. Research the Company and Position

Take the time to research the company you are applying to, their values, and the specific requirements of the Structural Steel Fitter position. This knowledge will enable you to tailor your answers to the interviewer’s questions and highlight how your qualifications align with the company’s needs.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivations. Practice answering these questions concisely and effectively, emphasizing your technical abilities, safety consciousness, and teamwork capabilities.

- Tell us about your experience in structural steel fabrication and installation.

- Describe your understanding of blueprint reading and interpretation.

- How do you ensure the quality and safety of your work?

3. Showcase Your Technical Knowledge

Highlight your proficiency in structural steel fabrication techniques, including welding, bolting, and riveting. Explain how you maintain and calibrate your tools and equipment to ensure accuracy and precision.

4. Emphasize Safety and Compliance

Emphasize your commitment to safety by describing your compliance with industry regulations and your adherence to established safety protocols. Mention any relevant certifications or training you have obtained, such as OSHA certification or First Aid/CPR training.

- Explain your understanding of fall protection and hazard assessment.

- Describe how you respond to emergencies on the job site.

5. Seek Opportunities to Ask Questions

Towards the end of the interview, take the opportunity to ask thoughtful questions that demonstrate your interest in the position and the company. This can also help you gauge the work environment and company culture.

- What are the expected deliverables and timelines for this role?

- Can you provide more information about the company’s safety program?

Next Step:

Now that you’re armed with the knowledge of Structural Steel Fitter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Structural Steel Fitter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini