Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Corrosion Control Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

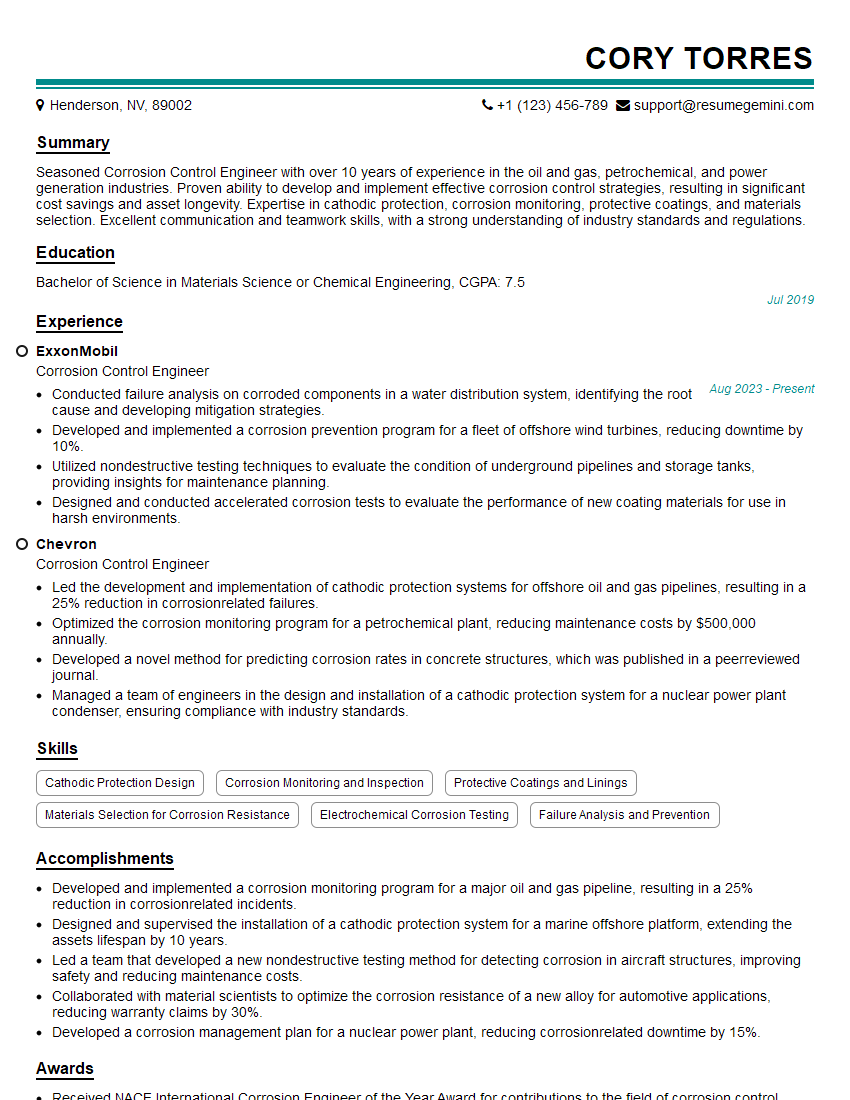

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corrosion Control Engineer

1. Explain the mechanism of galvanic corrosion and how it can be prevented?

- Galvanic corrosion occurs when two dissimilar metals are in electrical contact and exposed to an electrolyte.

- The more active metal (anode) corrodes, while the less active metal (cathode) is protected.

- Prevention methods include isolating the metals, using a sacrificial anode, or applying a protective coating.

2. Describe the NACE International standard RP0285 and its importance in corrosion control.

NACE RP0285

- Provides guidelines for the design, installation, and maintenance of cathodic protection systems.

- Ensures system effectiveness and longevity, reducing corrosion risks.

Importance

- Complies with industry standards and regulations.

- Optimizes protection levels, extending asset lifespan.

- Reduces maintenance costs and minimizes unplanned downtime.

3. Discuss the different types of corrosion inhibitors and their applications.

- Anodic inhibitors: Form a protective oxide layer on the metal surface, e.g., chromates, phosphates.

- Cathodic inhibitors: Prevent the reduction of oxygen or cathodic reactions, e.g., zinc salts, molybdates.

- Mixed inhibitors: Combine both anodic and cathodic inhibition mechanisms, e.g., benzotriazole.

- Applications include oil and gas pipelines, chemical processing equipment, and cooling water systems.

4. Explain the role of coatings in corrosion prevention and describe different types of coatings.

- Coatings act as a barrier between the metal surface and the corrosive environment.

- Types include:

- Organic coatings: Paints, epoxies, urethanes.

- Metallic coatings: Zinc, aluminum, stainless steel.

- Ceramic coatings: Glass, porcelain.

- Selection depends on factors such as the corrosive environment, temperature, and mechanical requirements.

5. Describe the methods used to monitor and evaluate corrosion in industrial systems.

- Visual inspections: Regular checks for signs of corrosion, such as rust, pitting, or discoloration.

- Electrochemical techniques: Measuring changes in electrical properties, e.g., electrochemical impedance spectroscopy (EIS).

- Non-destructive testing (NDT): Ultrasonic testing, radiography, or eddy current testing.

- Corrosion coupons: Placing sacrificial metal samples in the system to measure corrosion rates.

6. Discuss the importance of stress corrosion cracking (SCC) prevention in pipelines.

- SCC is a type of corrosion that occurs in materials under tensile stress and in the presence of a corrosive environment.

- It can lead to catastrophic failures in pipelines, resulting in leaks, explosions, or environmental damage.

- Prevention measures include material selection, stress reduction, and corrosion monitoring.

7. Explain the concept of cathodic disbondment and its impact on coated metal structures.

- Cathodic disbondment occurs when a coating is applied to a metal structure and the coating is more cathodic than the metal.

- This can cause the coating to become disbonded from the metal due to the formation of hydrogen gas at the metal-coating interface.

- Prevention measures include selecting compatible coating systems, ensuring proper surface preparation, and providing good electrical contact between the coating and the metal.

8. Describe the role of microbes in corrosion and discuss mitigation strategies.

- Microbes, such as sulfate-reducing bacteria (SRB), can accelerate corrosion in various environments, including pipelines, storage tanks, and cooling systems.

- SRB produce hydrogen sulfide, which can react with iron to form iron sulfide, leading to corrosion.

- Mitigation strategies include chemical treatments, biocides, and proper cleaning and disinfection practices.

9. Discuss the challenges and advancements in corrosion control for offshore structures.

Challenges

- Harsh marine environment: Seawater, high salinity, and temperature variations.

- Biofouling and marine growth.

- Complex structural design and access for maintenance.

Advancements

- Advanced coatings and materials.

- Remote monitoring and inspection technologies.

- Cathodic protection systems tailored for offshore environments.

10. Explain the importance of corrosion control in the oil and gas industry.

- Corrosion can lead to significant economic losses due to equipment failure, downtime, and safety hazards.

- Corrosion control measures protect pipelines, storage tanks, and other infrastructure, ensuring safe and reliable operations.

- Optimizing corrosion control strategies reduces maintenance costs and extends asset lifespan.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corrosion Control Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corrosion Control Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Corrosion Control Engineers play a crucial role in safeguarding infrastructure and assets from the detrimental effects of corrosion. Their key responsibilities encompass:

1. Corrosion Assessment and Monitoring

Conduct thorough inspections and assessments to identify and analyze corrosion threats in various environments.

- Evaluate corrosion mechanisms and determine their impact on asset integrity.

- Develop and implement monitoring programs to track corrosion rates and predict potential failures.

2. Corrosion Mitigation and Prevention

Design and implement corrosion protection strategies to minimize or eliminate corrosion risks.

- Specify and select appropriate corrosion-resistant materials and coatings.

- Utilize cathodic protection systems, inhibitors, and other methods to control corrosion.

3. Material Selection and Engineering

Provide guidance on the selection of corrosion-resistant materials for construction and maintenance.

- Advise on material compatibility and recommend protective measures for specific environments.

- Conduct corrosion testing to evaluate the effectiveness of materials and coatings.

4. Failure Analysis and Investigation

Investigate corrosion-related failures to determine root causes and develop preventive measures.

- Examine failed components and analyze corrosion mechanisms.

- Provide recommendations for design modifications or operational changes to mitigate future failures.

Interview Tips

Preparing for a Corrosion Control Engineer interview requires a well-rounded approach. Here are some tips and hacks to help you ace your interview:

1. Brush Up on Corrosion Basics

Ensure proficiency in key concepts like corrosion mechanisms, electrochemical principles, and corrosion testing methods.

- Review textbooks, scientific articles, and industry standards.

- Attend workshops or webinars to enhance your knowledge.

2. Highlight Your Practical Experience

Showcase your hands-on experience in corrosion control and mitigation. Quantify your accomplishments using specific examples.

- Describe successful corrosion assessments you have conducted and the impact they had.

- Provide details on corrosion protection systems you have designed or implemented.

3. Demonstrate Your Analytical Skills

Emphasize your ability to analyze corrosion data and develop solutions. Use the STAR method to structure your answers.

- Situation: Describe the specific situation or problem you encountered.

- Task: Explain your role and responsibilities in addressing the issue.

- Action: Outline the steps you took to analyze the problem and develop a solution.

- Result: Quantify the outcomes and impact of your actions.

4. Be Industry Aware

Stay up-to-date with the latest industry trends and technologies. Research current advancements in corrosion control.

- Subscribe to industry publications and attend conferences.

- Network with professionals in the field.

5. Practice Mock Interviews

Engage in mock interviews to enhance your confidence and refine your answers. Seek feedback from peers or mentors.

- Prepare a list of potential interview questions and practice your responses.

- Record yourself answering questions to identify areas for improvement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Corrosion Control Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!