Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Firebrick or Refractory Tile Bricklayer Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Firebrick or Refractory Tile Bricklayer Helper so you can tailor your answers to impress potential employers.

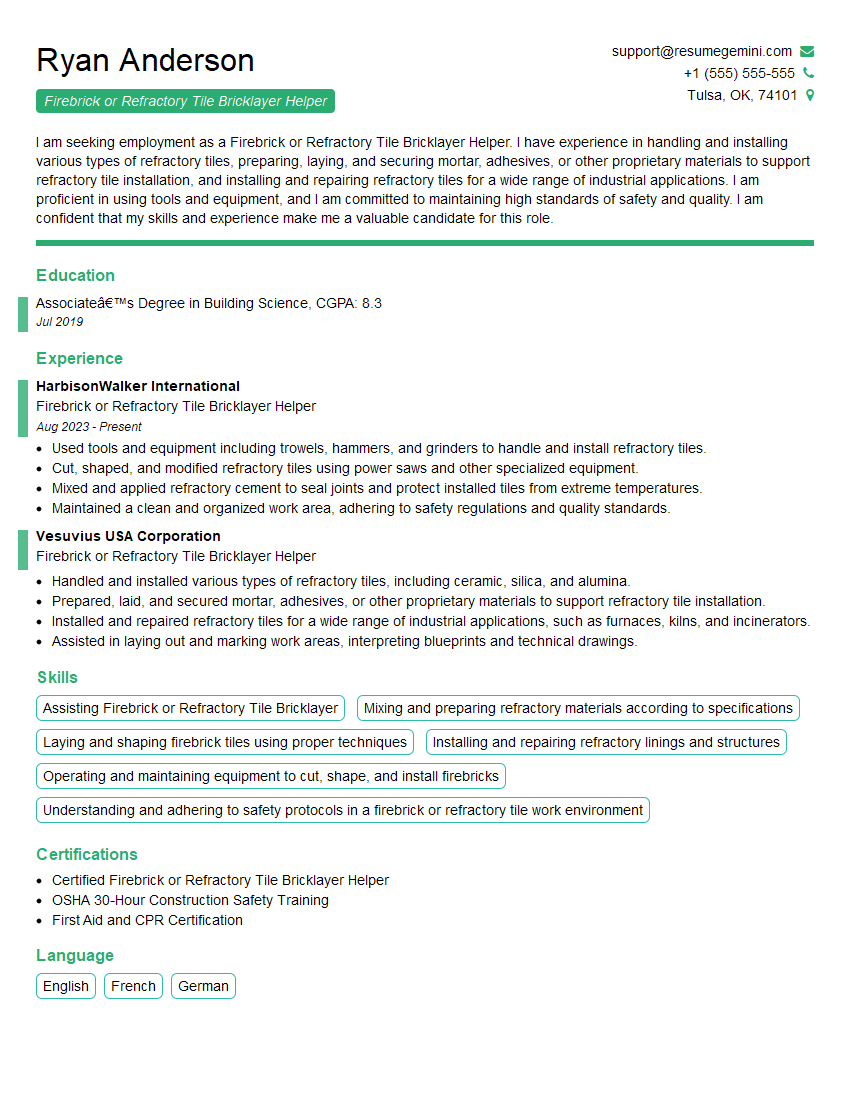

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Firebrick or Refractory Tile Bricklayer Helper

1. Describe the process of installing firebrick in a furnace?

The process of installing firebrick in a furnace involves several steps:

- Preparing the furnace: The furnace must be cleaned and any existing refractory materials removed.

- Laying out the firebrick: The firebrick is laid out in a dry-fit pattern to ensure proper alignment and fit.

- Mixing and applying mortar: A refractory mortar is mixed and applied to the firebrick joints, bonding them together.

- Setting the firebrick: The firebrick is set in place and pressed firmly into the mortar.

- Curing the mortar: The mortar is allowed to cure and harden, creating a strong bond between the firebrick.

2. How do you measure and cut firebrick to the desired shape and size?

Using a Firebrick Saw

- Mark the cutting line on the firebrick using a chalk line or pencil.

- Secure the firebrick in a firebrick saw, ensuring it is stable and will not move during cutting.

- Start the saw and slowly feed the firebrick through the blade, maintaining a steady pressure.

Using a Grinder with a Diamond Blade

- Mark the cutting line on the firebrick.

- Wear appropriate safety gear, including eye protection, gloves, and a dust mask.

- Secure the firebrick and start the grinder.

- Slowly and carefully follow the marked line while grinding, taking care not to apply excessive pressure.

3. What safety precautions should be taken when working with firebrick?

- Wear appropriate protective gear: This includes safety glasses, gloves, respirators, and protective clothing.

- Handle firebrick with care: Firebrick is heavy and can cause injury if dropped or handled improperly.

- Be aware of sharp edges: Firebrick can have sharp edges that can cause cuts or abrasions.

- Avoid inhaling dust: Firebrick dust can irritate the lungs, so wear a respirator when cutting or grinding.

- Store firebrick properly: Firebrick should be stored in a dry, well-ventilated area to prevent moisture absorption.

4. What types of tools and equipment are commonly used by a Firebrick or Refractory Tile Bricklayer Helper?

- Firebrick saw

- Grinder with diamond blade

- Hammer and chisel

- Mortar mixer

- Trowel

- Safety glasses

- Gloves

- Respirator

5. How do you ensure that the firebrick installation meets the required specifications and quality standards?

- Follow the manufacturer’s instructions: Adhere to the specified mortar mix ratios, application methods, and curing times.

- Check the firebrick for damage: Inspect each firebrick before installation to ensure it is free from cracks or other defects.

- Maintain proper joint spacing: Use spacers or guides to maintain consistent joint widths and ensure proper bonding.

- Cure the mortar properly: Allow the mortar to cure according to the manufacturer’s recommendations to achieve maximum strength.

- Inspect the finished installation: Once the mortar has cured, thoroughly inspect the installation for any gaps, cracks, or other imperfections.

6. What types of refractory materials are commonly used in furnace linings, and what are their properties?

- Fireclay bricks: Made from fireclay and grog, they offer high refractoriness and resistance to thermal shock.

- High alumina bricks: Contain high levels of alumina and have excellent resistance to wear, corrosion, and slag attack.

- Silica bricks: Made from silica, they have high strength and are used in linings exposed to high temperatures.

- Magnesia bricks: Composed of magnesia, they are highly resistant to basic slags and are commonly used in steelmaking furnaces.

- Chrome-magnesite bricks: A blend of chrome ore and magnesia, they offer resistance to both acidic and basic slags.

7. How do you prepare a mortar mix for firebrick installation?

- Determine the correct mix ratio: Refer to the manufacturer’s instructions for the specific type of mortar being used.

- Mix dry ingredients: Combine the dry ingredients, such as fireclay powder and sand, in a mortar mixer.

- Add water gradually: Slowly add water while mixing until the desired consistency is achieved. The mortar should be workable but not too wet.

- Mix thoroughly: Continue mixing until the mortar is uniform and free of lumps.

- Allow the mix to slake: Let the mortar mixture slake for a period of time before using to allow for proper hydration.

8. Describe the different types of bonds used in firebrick construction and their advantages?

- Stretcher bond: Bricks are laid in alternating rows, with the long side exposed.

- Header bond: Bricks are laid perpendicular to the wall, with the ends exposed.

- Flemish bond: Alternating rows of stretchers and headers, creating a decorative pattern.

- English bond: Bricks are laid in a repeating pattern of three stretchers followed by one header.

- Stack bond: Bricks are laid directly on top of each other, without any offset.

9. How do you troubleshoot and repair cracks or damage in a firebrick lining?

- Identify the cause of the damage: Determine whether the cracks or damage are due to thermal stress, mechanical stress, or chemical attack.

- Remove the damaged firebrick: Carefully remove the damaged firebrick using a hammer and chisel or other appropriate tools.

- Prepare the area for repair: Clean the area where the new firebrick will be installed and remove any loose or damaged mortar.

- Install the new firebrick: Place the new firebrick in the prepared area and secure it with mortar.

- Cure the mortar: Allow the mortar to cure properly before putting the furnace back into operation.

10. How do you maintain and extend the lifespan of a firebrick lining in a furnace?

- Regular inspections: Regularly inspect the firebrick lining for any signs of damage or wear.

- Proper operation: Ensure the furnace is operated within the specified temperature range and avoid rapid temperature changes.

- Repairs: Promptly repair any cracks or damage to the lining to prevent further deterioration.

- Preventive maintenance: Perform regular maintenance tasks, such as cleaning and inspecting the furnace, to prevent issues from occurring.

- Furnace shutdown: Follow proper shutdown procedures to minimize thermal stress on the firebrick lining.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Firebrick or Refractory Tile Bricklayer Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Firebrick or Refractory Tile Bricklayer Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Firebrick or Refractory Tile Bricklayer Helper plays a crucial role in supporting Firebrick or Refractory Tile Bricklayers, ensuring the efficient and safe installation of refractory tiles and bricks in industrial furnaces and other high-temperature applications.

1. Assisting in Material Preparation

Assists in preparing and gathering materials required for bricklaying, such as refractory bricks, tiles, mortars, and adhesives.

- Loads and unloads materials from trucks and storage areas.

- Prepares mortars and adhesives according to specified ratios.

2. Assisting in Bricklaying

Assists bricklayers in installing refractory bricks and tiles by mixing mortars, preparing surfaces, and handling materials.

- Mixes and applies mortars and adhesives to designated areas.

- Positions refractory bricks and tiles accurately according to blueprints and instructions.

3. Maintaining Work Area

Maintains a clean and organized work area, ensuring a safe and efficient environment.

- Sweeps and cleans work surfaces, removing debris and excess materials.

- Inspects equipment and tools regularly, reporting any malfunctions or damage.

4. Safety and Compliance

Adheres to all safety regulations and protocols, ensuring the protection of self and others.

- Wears appropriate personal protective equipment (PPE) such as gloves, safety glasses, and respirators.

- Follows safe work practices, including proper lifting techniques and using designated work areas.

Interview Tips

Preparing for an interview for a Firebrick or Refractory Tile Bricklayer Helper position requires a combination of technical knowledge, practical experience, and a strong understanding of the industry.

1. Research the Industry and Company

Familiarize yourself with the refractory industry and the specific company you are applying to. Research their products, services, and target markets.

- Visit the company website and social media pages for information about their operations and culture.

- Read industry publications and articles to gain insights into current trends and best practices.

2. Highlight Your Skills and Experience

Emphasize your experience in assisting bricklayers and your familiarity with refractory materials and techniques.

- Quantify your accomplishments by providing specific examples of your contributions to previous projects.

- Showcase your understanding of different types of refractory bricks and mortars, as well as their properties and applications.

3. Demonstrate Your Safety Awareness

Safety is paramount in the refractory industry. Emphasize your commitment to following safety regulations and your experience in maintaining a safe work environment.

- Highlight your knowledge of industry-specific hazards and the measures you take to mitigate them.

- Discuss your experience with using personal protective equipment (PPE) and your adherence to safe work practices.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that demonstrate your qualifications.

- Tell me about your experience in assisting bricklayers.

- What types of refractory materials are you familiar with?

- Describe your approach to safety in a high-temperature work environment.

- Why are you interested in working for our company?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Firebrick or Refractory Tile Bricklayer Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.