Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Epoxy Coatings Installer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Epoxy Coatings Installer so you can tailor your answers to impress potential employers.

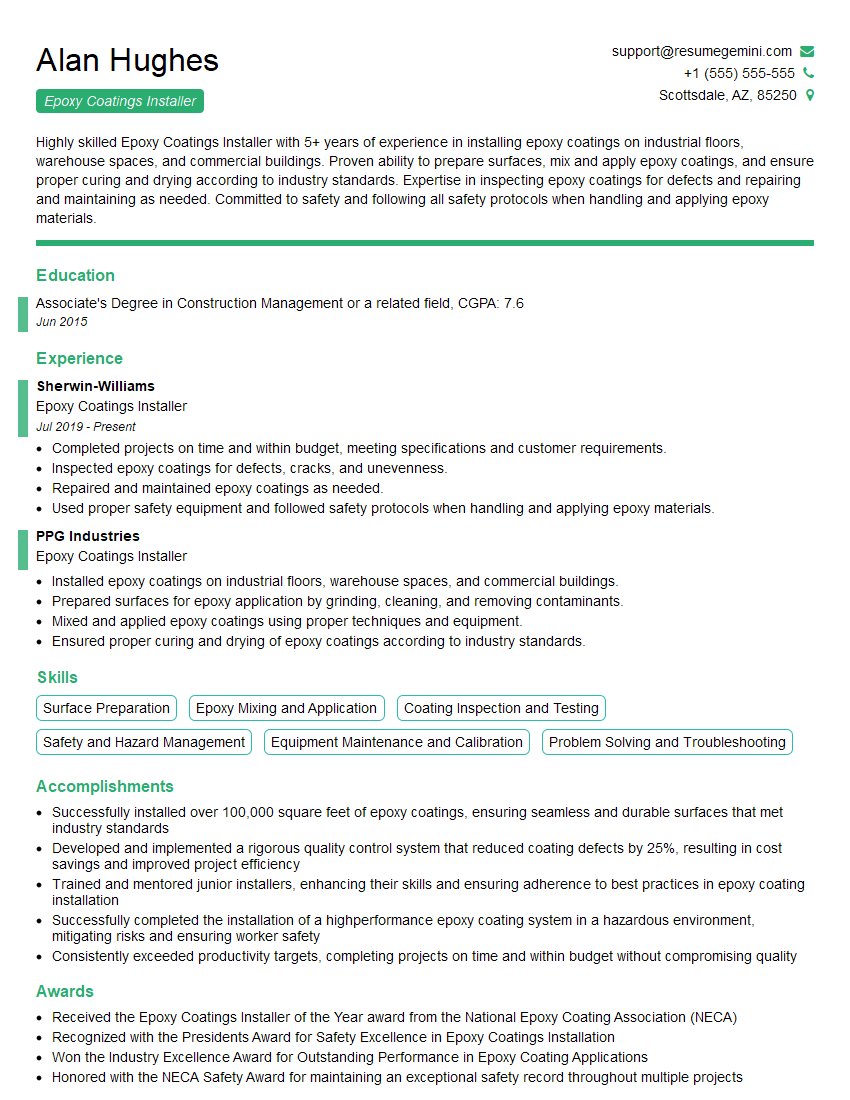

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Epoxy Coatings Installer

1. What are the key steps involved in preparing a surface for epoxy coating application?

- Cleaning: Remove dirt, oil, grease, and other contaminants using a degreaser or detergent.

- Abrading: Roughen the surface to promote adhesion using a grinder, sander, or shot blaster.

- Priming: Apply a primer to enhance adhesion and protect the surface from moisture and chemicals.

2. What factors influence the choice of epoxy coating system for a specific application?

Considerations for Epoxy Coating Selection

- Substrate type and condition

- Environmental conditions (temperature, humidity, chemical exposure)

- Expected wear and tear

- Desired finish and color

Factors Influencing Epoxy Coating System

- Chemical resistance

- Abrasion resistance

- UV resistance

- Flexibility

3. How do you ensure proper mixing and application of epoxy coatings?

To ensure proper mixing and application, I follow these steps:

- Calculate the correct mix ratio and use high-quality measuring equipment to avoid errors.

- Thoroughly mix the components using a drill and mixing paddle or dedicated mixing equipment.

- Scrape the sides and bottom of the mixing container to ensure even distribution of the components.

- Allow the mixed epoxy to degas for the specified time to release any trapped air bubbles.

- Apply the epoxy using recommended methods (roller, brush, or spray) within the specified pot life.

4. What are the potential hazards associated with epoxy coatings, and how do you mitigate them?

- Chemical exposure: Use proper protective equipment (PPE), including gloves, mask, and eye protection.

- Fumes: Ensure adequate ventilation or use respirators when working in enclosed areas.

- Skin irritation: Use barrier creams, wear protective clothing, and wash thoroughly after handling epoxy.

- Fire hazard: Keep epoxy away from heat sources and follow proper storage and disposal guidelines.

5. What are the different techniques for applying epoxy coatings, and when is each one most appropriate?

Techniques for Applying Epoxy Coatings

- Rolling: Suitable for large, flat surfaces, provides a smooth finish with minimal texture.

- Brushing: Ideal for small areas, complex shapes, or intricate details.

- Spraying: Efficient for applying epoxy to large or hard-to-reach surfaces, allows for precise application.

Appropriateness

- Rolling: Floors, walls, ceilings

- Brushing: Corners, edges, small repairs

- Spraying: Warehouses, industrial facilities, exterior surfaces

6. How do you inspect an epoxy coating for quality, and what are the common defects to look for?

Inspection Techniques

- Visual examination for smoothness, sheen, and uniformity.

- Dry film thickness measurement to ensure proper application thickness.

- Adhesion testing to assess the bond between the coating and the substrate.

Common Defects

- Bubbles and pinholes

- Cracking and peeling

- Discoloration and yellowing

- Uneven or rough texture

7. What are the best practices for maintaining epoxy coatings to ensure their longevity and performance?

- Regular cleaning to remove dirt and debris.

- Avoid using harsh chemicals or abrasive cleaners.

- Touch up any damaged areas promptly using a compatible epoxy repair kit.

- Periodic inspections for signs of wear and tear or degradation.

- Recoat as necessary to maintain the desired level of protection and aesthetics.

8. Have you worked with any specialized epoxy coatings, such as antimicrobial or conductive coatings?

Yes, I have experience working with specialized epoxy coatings, including antimicrobial and conductive coatings.

Antimicrobial Coatings

- Inhibited the growth of bacteria, mold, and mildew.

- Used in healthcare facilities, food processing plants, and other applications where hygiene is critical.

Conductive Coatings

- Dissipated static electricity.

- Used in electronic manufacturing facilities, clean rooms, and other environments where static discharge control is essential.

9. What safety precautions should be taken when working with different types of epoxy coatings?

Safety Precautions

- Wear appropriate PPE, including gloves, mask, and eye protection.

- Ensure adequate ventilation to avoid inhaling fumes.

- Keep epoxy away from heat sources to prevent fire hazards.

- Follow proper storage and disposal guidelines provided by the manufacturer.

Specific Considerations

- For solvent-based epoxies: Use in well-ventilated areas and avoid skin contact.

- For water-based epoxies: Less toxic but still require proper PPE and ventilation.

- For conductive epoxies: Wear anti-static clothing and footwear to prevent electric shock.

10. How do you stay updated on the latest advancements and best practices in epoxy coating technology?

- Attend industry conferences and workshops.

- Subscribe to trade publications and online resources.

- Consult with manufacturers and suppliers for technical support and product information.

- Participate in online forums and discussion groups.

- Conduct research and stay informed about new products, techniques, and standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Epoxy Coatings Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Epoxy Coatings Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Epoxy Coatings Installers apply epoxy coatings to protect and enhance various surfaces in commercial, industrial, and residential settings. Their key responsibilities include:

1. Surface Preparation and Inspection

Preparing surfaces by grinding, cleaning, and repairing any imperfections or cracks to ensure proper adhesion of epoxy coatings.

- Assessing surface conditions, identifying and addressing any defects or irregularities.

- Selecting and utilizing appropriate cleaning methods and equipment to remove dirt, oil, and other contaminants.

- Repairing damaged surfaces by filling cracks and holes with epoxy resin or other suitable materials.

2. Epoxy Coating Application

Applying epoxy coatings using various techniques, such as roller, brush, or spray equipment, according to specified requirements.

- Mixing and preparing epoxy resins and hardeners in precise ratios to achieve optimal performance.

- Applying multiple layers of epoxy coatings, ensuring proper thickness and even distribution.

- Smoothing and leveling epoxy surfaces to eliminate any bumps or imperfections.

3. Curing and Maintenance

Monitoring epoxy coatings during the curing process, ensuring proper hardening and adherence to specifications.

- Controlling environmental conditions, such as temperature and humidity, to optimize curing times.

- Inspecting cured epoxy coatings to ensure they meet the desired finish and performance standards.

- Performing routine maintenance and repairs on epoxy coatings as needed to maintain their integrity and longevity.

4. Safety and Compliance

Adhering to safety protocols and using personal protective equipment (PPE) when handling and applying epoxy coatings.

- Understanding and implementing proper ventilation techniques to minimize exposure to vapors and fumes.

- Following established mixing and application procedures to ensure safe and effective use of epoxy materials.

- Disposing of hazardous waste and materials in accordance with environmental regulations.

Interview Tips

To prepare for an interview for an Epoxy Coatings Installer position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, services, and reputation in the industry. Research trends and innovations in epoxy coatings to demonstrate your knowledge and interest.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and attend webinars to stay updated on the latest advancements.

2. Highlight Relevant Skills and Experience

Emphasize your skills in surface preparation, epoxy coating application, and maintenance procedures. Quantify your experience whenever possible to demonstrate your impact.

- Describe instances where you successfully resolved surface preparation challenges or achieved exceptional results in epoxy coating applications.

- Provide examples of projects where you ensured proper curing and adherence to specifications.

3. Showcase Safety and Compliance Knowledge

Demonstrate your understanding of safety protocols and environmental regulations related to epoxy coatings. Explain how you prioritize safety in your work practices.

- Describe your experience in using PPE and adhering to proper ventilation techniques.

- Explain your knowledge of hazardous waste disposal procedures and environmental compliance.

4. Practice Common Interview Questions

Prepare for common interview questions by researching typical questions asked in this field. Practice answering these questions clearly and concisely.

- Tell me about your experience with epoxy coating installation.

- How do you ensure proper surface preparation before applying epoxy coatings?

- What are the safety precautions you take when working with epoxy materials?

5. Be Enthusiastic and Professional

Convey your enthusiasm for epoxy coatings and your commitment to delivering high-quality work. Maintain a professional demeanor throughout the interview, ask thoughtful questions, and express gratitude for the opportunity.

- Share your passion for the industry and explain why you’re excited about this role.

- Ask questions about the company’s projects and your potential responsibilities.

- Thank the interviewer for their time and consideration.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Epoxy Coatings Installer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.