Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Engineer, Methods interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Engineer, Methods so you can tailor your answers to impress potential employers.

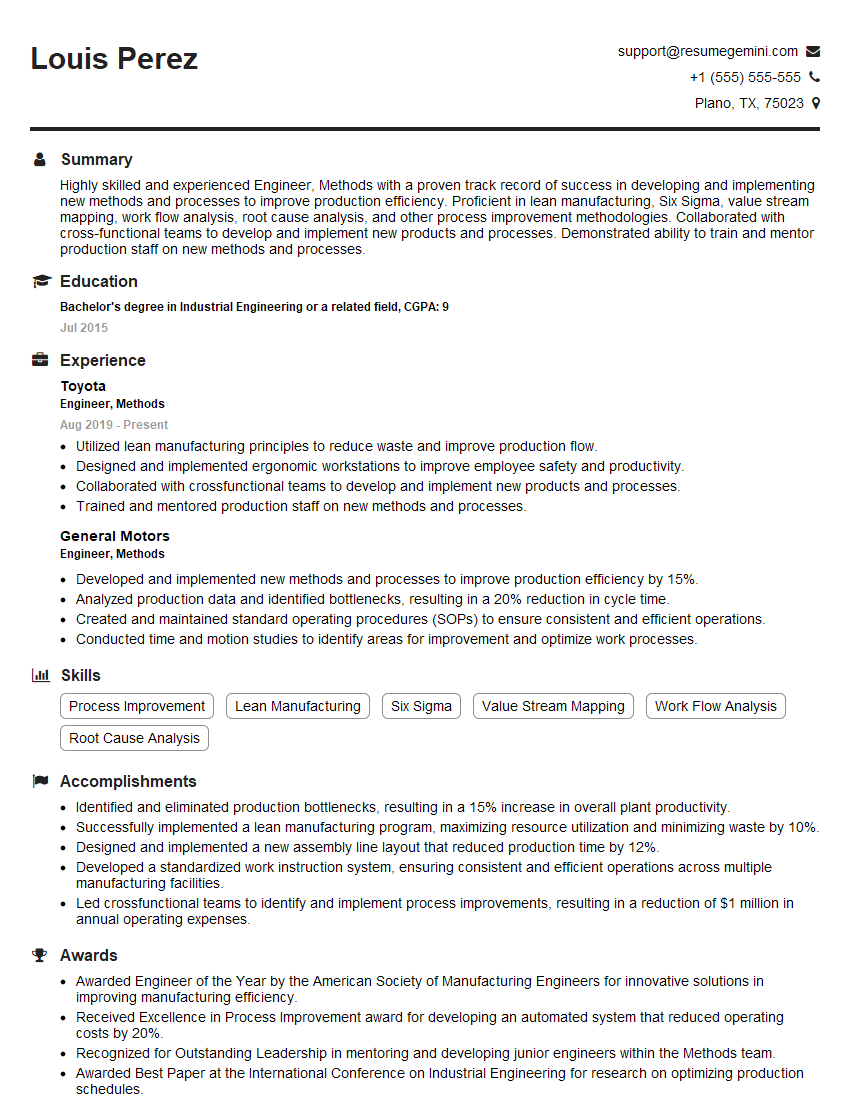

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Engineer, Methods

1. Describe your approach to developing and implementing new manufacturing processes?

– Identify Business Needs: Understand the specific manufacturing requirements and pain points. – Research and Evaluate: Explore various technologies, equipment, and methodologies aligned with the needs. – Process Design: Develop a detailed design for the new process, considering factors such as efficiency, quality, and cost. – Pilot Implementation: Test the process on a small scale to validate its feasibility and identify areas for improvement. – Full-Scale Implementation: Roll out the process across the production line after successful pilot testing. – Continuous Improvement: Monitor and evaluate the process performance and make adjustments as needed to optimize efficiency and quality.

2. Explain your experience in optimizing existing production processes.

Process Analysis

- Analyze production data to identify bottlenecks and inefficiencies.

- Conduct time and motion studies to optimize operator movements and reduce cycle time.

Equipment Modifications

- Suggest modifications to machinery or tooling to improve performance and reduce downtime.

- Evaluate and implement automation solutions to enhance efficiency and consistency.

Process Improvements

- Develop new work instructions and standard operating procedures to streamline production.

- Implement lean manufacturing principles to eliminate waste and improve overall process flow.

3. How do you stay updated on the latest advancements in manufacturing technology?

- Attend industry conferences and exhibitions to learn about new equipment, techniques, and best practices.

- Subscribe to industry publications and online forums to stay informed about emerging trends.

- Network with fellow professionals and experts in the field to exchange knowledge and insights.

- Engage in research and development initiatives to explore innovative solutions and advance manufacturing capabilities.

4. Describe your experience in designing and implementing automated systems in manufacturing.

- Analyze production processes to identify areas suitable for automation.

- Research and evaluate different automation technologies, including robotics, conveyors, and sensors.

- Design and develop automation systems that meet specific production requirements and safety standards.

- Integrate automated systems into existing production lines, ensuring seamless operation and improved efficiency.

- Train operators on the use and maintenance of automated systems.

5. How do you approach quality control and assurance in manufacturing?

- Establish clear quality standards and specifications based on customer requirements.

- Implement inspection and testing procedures at critical points in the production process.

- Use statistical process control techniques to monitor and evaluate product quality.

- Identify and address root causes of quality defects to prevent recurrence.

- Maintain documentation and records to demonstrate compliance with quality standards.

6. Describe your experience in lean manufacturing and continuous improvement.

Lean Principles

- Identify and eliminate waste in all aspects of production.

- Streamline processes and reduce cycle times.

- Improve inventory management and reduce lead times.

Continuous Improvement

- Implement a culture of continuous process evaluation and improvement.

- Use tools such as Kaizen and Six Sigma to identify and resolve issues.

- Encourage employee involvement in improvement initiatives.

7. How do you manage a team of engineers and technicians in a manufacturing environment?

- Establish clear roles and responsibilities for each team member.

- Provide regular training and development opportunities to enhance team skills.

- Foster a collaborative and supportive environment to encourage teamwork and innovation.

- Set realistic goals and provide regular feedback to motivate and guide the team.

- Empower team members to make decisions and take ownership of their work.

8. Describe your project management approach for large-scale manufacturing projects.

- Define clear project scope, objectives, and deliverables.

- Develop a detailed project plan, including timelines, resource allocation, and risk management strategies.

- Monitor project progress and make necessary adjustments to ensure timely completion.

- Communicate effectively with stakeholders throughout the project lifecycle.

- Document project outcomes and lessons learned to inform future projects.

9. How do you evaluate the cost-effectiveness of new manufacturing processes or technologies?

- Estimate upfront investment costs, including equipment, labor, and training.

- Project future operating costs, such as energy consumption, maintenance, and materials.

- Calculate the potential return on investment based on increased productivity, reduced defects, or improved lead times.

- Consider the long-term impact on product quality and customer satisfaction.

- Make recommendations based on a comprehensive cost-benefit analysis.

10. Describe your experience in troubleshooting and resolving manufacturing issues.

- Analyze production data and identify patterns or anomalies.

- Perform root cause analysis to determine the underlying causes of issues.

- Develop and implement solutions to address the root causes.

- Monitor the effectiveness of solutions and make adjustments as needed.

- Document troubleshooting processes and share learnings with the team to prevent recurrence.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Engineer, Methods.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Engineer, Methods‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Engineer, Methods is responsible for developing, implementing, and maintaining methods and processes to improve efficiency and productivity within an organization. The key job responsibilities include:

1. Process Analysis and Improvement

Analyze current processes and identify areas for improvement. Develop and implement new methods and processes to streamline operations and reduce waste.

- Conduct time studies and work measurements to identify inefficiencies.

- Develop and implement new work standards and procedures.

2. Equipment and Tool Design

Design and specify equipment and tools to improve production efficiency. Collaborate with engineers and technicians to develop and implement solutions.

- Design and develop new equipment and tools to improve productivity.

- Modify existing equipment and tools to meet specific production requirements.

3. Training and Development

Train and develop employees on new methods and processes. Provide ongoing support to ensure that employees are using methods effectively.

- Develop and deliver training programs on new methods and processes.

- Provide ongoing coaching and support to employees to ensure proper implementation.

4. Data Analysis and Reporting

Collect and analyze data to track progress and identify opportunities for further improvement. Prepare reports and presentations to communicate findings.

- Collect and analyze data on production efficiency and process effectiveness.

- Prepare reports and presentations to communicate findings and recommendations.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for an Engineer, Methods role:

1. Research the Company and Position

Take the time to research the company and the specific Engineer, Methods position you are applying for. Understanding the company’s culture, values, and goals will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages to learn about their products, services, and recent news.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies in the field.

2. Practice Your Answers

Once you have a good understanding of the company and the position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your experience.

- Practice answering questions about your skills, experience, and motivations.

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. It also gives you the opportunity to clarify any information and to learn more about the role.

- Prepare questions about the company’s culture, growth plans, and commitment to innovation.

- Ask about the specific responsibilities and expectations of the Engineer, Methods role.

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally for your interview. Arrive on time and be prepared to start the interview promptly.

- Wear a suit or business casual attire.

- Be respectful of the interviewer’s time and arrive on schedule.

Next Step:

Now that you’re armed with the knowledge of Engineer, Methods interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Engineer, Methods positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini