Feeling lost in a sea of interview questions? Landed that dream interview for Process Manufacturing Engineer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Process Manufacturing Engineer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

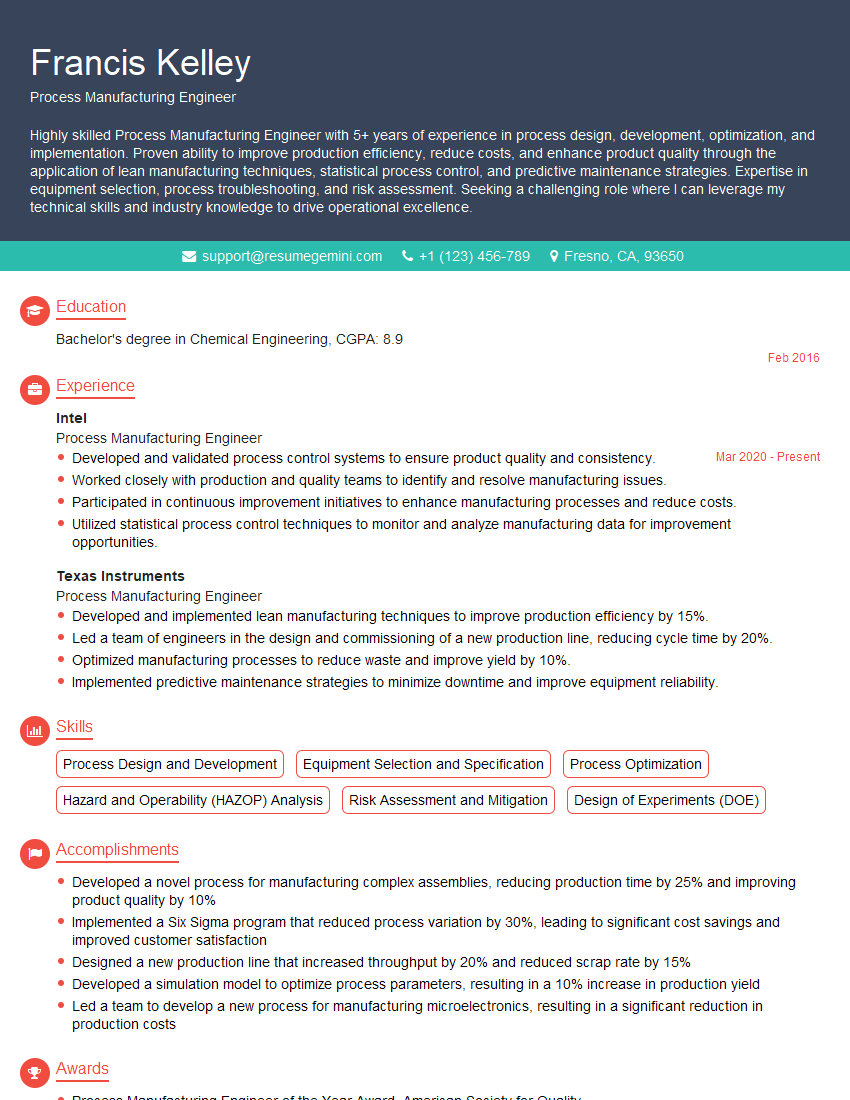

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Process Manufacturing Engineer

1. Describe the key responsibilities of a Process Manufacturing Engineer in the pharmaceutical industry?

- Develop, optimize, and validate manufacturing processes for pharmaceutical products.

- Design and evaluate process equipment and systems.

- Troubleshoot and resolve manufacturing issues, ensuring efficient and high-quality production.

- Collaborate with cross-functional teams to improve process performance and meet regulatory requirements.

- Stay abreast of industry best practices and technological advancements in manufacturing.

2. How do you apply quality assurance principles and techniques to enhance process manufacturing?

Define quality assurance principles

- Establish clear quality standards and specifications.

- Implement monitoring and testing systems to assess process performance.

- Identify and eliminate potential sources of contamination or errors.

Describe quality assurance techniques

- Perform risk assessments to identify potential hazards and develop mitigation strategies.

- Utilize statistical process control techniques to monitor and improve process stability.

- Conduct periodic audits and inspections to ensure compliance with quality standards.

3. Explain the role of automation in modern process manufacturing and provide examples?

- Automate repetitive and labor-intensive tasks to increase efficiency and reduce human error.

- Use sensors and control systems to monitor and adjust process parameters in real-time.

- Integrate robotics to perform complex and delicate operations with precision.

- Example: Automated tablet press machines, robotic arm for sterile filling lines, sensor-based monitoring of temperature and pressure.

4. Describe the importance of process validation and how it ensures product quality and compliance?

- Provides documented evidence that a manufacturing process consistently meets pre-determined specifications.

- Ensures product quality by eliminating errors and minimizing variability during production.

- Helps meet regulatory requirements set by agencies such as the FDA and EMA.

- Involves conducting qualification studies, monitoring process performance, and making adjustments as needed.

5. How do you approach problem-solving in process manufacturing, considering the need for efficiency and cost-effectiveness?

- Define the problem clearly and gather all relevant data.

- Identify potential root causes and develop hypotheses.

- Design and implement experiments or investigations to test hypotheses.

- Analyze results and determine the most effective solution.

- Prioritize solutions based on cost, efficiency, and impact on product quality.

6. Explain the concept of Six Sigma and its application in process manufacturing?

- A data-driven approach focused on continuous improvement and defect reduction.

- Uses statistical methods and tools to identify and eliminate sources of variation in processes.

- Aims to achieve near-zero defects or errors by identifying and addressing root causes.

- In manufacturing, Six Sigma is used to enhance product quality, reduce waste, and increase efficiency.

7. How do you keep up with advancements in process manufacturing and emerging technologies?

- Attend conferences and workshops to learn about new technologies and industry trends.

- Read technical journals and publications to stay informed about advancements in manufacturing.

- Collaborate with experts and thought leaders in the field.

- Participate in research and development projects to explore innovative solutions.

8. Describe your experience in optimizing a manufacturing process to meet specific quality or efficiency requirements?

- Conducted a detailed analysis of the existing process to identify bottlenecks and inefficiencies.

- Identified inefficiencies and potential areas for improvement, such as equipment upgrades, process parameter adjustments, or automation.

- Evaluated potential solutions and developed a plan to implement the identified changes.

- Implemented the changes and monitored the results, making further adjustments as needed.

- Successfully improved process efficiency and met the specified quality requirements.

9. How do you handle a situation where a critical piece of equipment fails during production, and your team is under pressure to meet delivery deadlines?

- Assess the situation and evaluate the impact on production schedules.

- Work with maintenance personnel to diagnose and repair the equipment as quickly as possible.

- Develop a contingency plan to minimize the impact on production, such as adjusting production rates or using alternative equipment.

- Communicate regularly with the team and stakeholders to keep them informed of the situation and potential delays.

- Prioritize urgent orders and explore alternative production options, if necessary.

10. Describe your approach to continuous improvement in a manufacturing environment?

- Regularly review and evaluate manufacturing processes to identify areas for improvement.

- Involve team members in the continuous improvement process to gather diverse perspectives and ideas.

- Implement small, incremental changes that can be easily tested and evaluated.

- Use data and metrics to track the impact of changes and make further adjustments as needed.

- Foster a culture of continuous improvement within the team, encouraging suggestions and feedback.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Process Manufacturing Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Process Manufacturing Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Process Manufacturing Engineers are responsible for developing and implementing manufacturing processes in a variety of industries, including pharmaceuticals, chemicals, food, and electronics. They work closely with other engineers, scientists, and production personnel to ensure that products are manufactured efficiently and meet all quality standards.

1. Process Development and Improvement

Process Manufacturing Engineers are tasked with developing new manufacturing processes and improving existing ones. This involves evaluating the efficiency and effectiveness of current processes, identifying areas for improvement, and implementing new technologies and techniques.

- Analyze existing manufacturing processes to identify areas for improvement.

- Develop and implement new manufacturing processes to improve efficiency and productivity.

- Troubleshoot and resolve manufacturing problems.

2. Equipment Selection and Maintenance

Process Manufacturing Engineers also play a role in selecting and maintaining manufacturing equipment. They work with vendors to identify the best equipment for their needs and ensure that it is properly installed and maintained.

- Select and purchase manufacturing equipment.

- Install and maintain manufacturing equipment.

- Train operators on how to use manufacturing equipment.

3. Production Planning and Control

Process Manufacturing Engineers are responsible for planning and controlling production schedules. They work with sales and marketing teams to forecast demand and develop production plans that meet those demands.

- Develop production plans and schedules.

- Monitor production progress and make adjustments as needed.

- Troubleshoot and resolve production problems.

4. Quality Control and Assurance

Process Manufacturing Engineers are also responsible for ensuring that products meet all quality standards. They work with quality control personnel to develop and implement quality control procedures and ensure that products are tested and inspected to meet those standards.

- Develop and implement quality control procedures.

- Test and inspect products to ensure that they meet quality standards.

- Troubleshoot and resolve quality problems.

Interview Tips

To ace the interview for a Process Manufacturing Engineer position, it is important to be well-prepared and to have a thorough understanding of the job responsibilities. Here are a few tips to help you prepare:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture, values, and goals, and to tailor your answers to the interviewer’s questions.

- Visit the company’s website and read about their history, mission, and products/services.

- Read the job description carefully and identify the key skills and experience that the employer is looking for.

- Look for news articles or industry blogs that mention the company or the position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Write out your answers to common interview questions and practice saying them aloud.

- Ask a friend or family member to conduct a mock interview with you.

- Time yourself to make sure that your answers are concise and within the time limit.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will likely ask you to talk about your experience and skills as they relate to the job responsibilities. Be prepared to give specific examples of your work experience and how it has prepared you for this position.

- Make a list of your relevant skills and experience, and be prepared to discuss them in detail.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Be prepared to talk about your strengths and weaknesses, and how you plan to overcome your weaknesses.

4. Prepare Questions for the Interviewer

At the end of the interview, the interviewer will likely ask if you have any questions for them. This is your opportunity to learn more about the company, the position, and the interviewer. Prepare a few thoughtful questions to ask, such as:

- What is the biggest challenge facing the company right now?

- What is the most important quality that you are looking for in a candidate for this position?

- What is the company’s culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Process Manufacturing Engineer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.