Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Manufacturing Systems Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

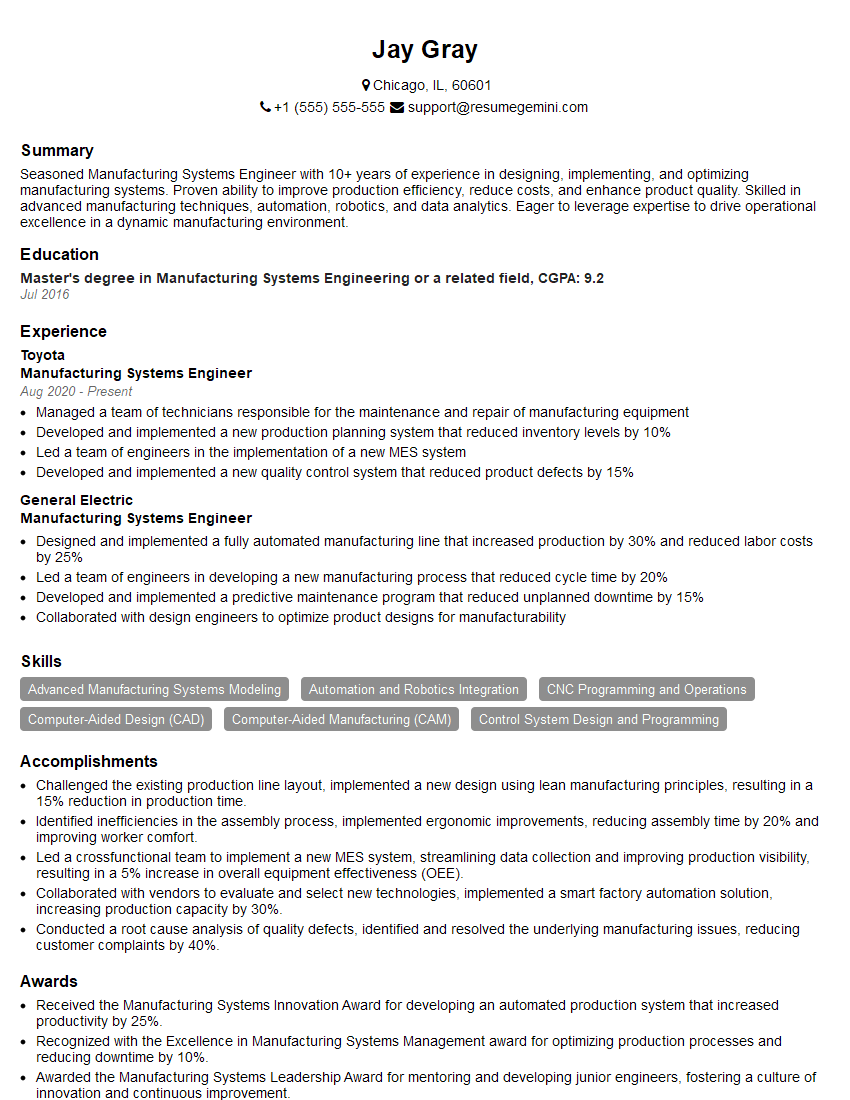

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manufacturing Systems Engineer

1. Describe the key elements of a manufacturing system, and explain how they interact with each other?

A manufacturing system consists of several key elements that work together to produce goods or services. These elements include:

- Input: Raw materials, components, and information required for production.

- Process: Transformation or conversion of inputs into outputs using various technologies and methods.

- Output: Finished products or services resulting from the manufacturing process.

- Control: Mechanisms and systems used to monitor, adjust, and optimize the manufacturing process.

- Feedback: Information gathered from the process to make necessary adjustments and improve performance.

These elements interact in a continuous cycle, where inputs are transformed into outputs, and feedback is used to improve the process over time.

2. How do you approach the design of a new manufacturing system?

Conceptualization and Planning

- Define project objectives, constraints, and desired outcomes.

- Gather data on existing operations, market demand, and potential technologies.

- Develop conceptual designs, considering process flow, capacity requirements, and equipment selection.

Detailed Design and Implementation

- Create detailed system specifications, including equipment layouts, process parameters, and control systems.

- Procure and install equipment, develop operating procedures, and train personnel.

- Commission and optimize the system to ensure it meets performance requirements.

3. Explain the different types of manufacturing processes and how to choose the most appropriate one for a specific product?

Manufacturing processes can be classified into various types based on the nature of the transformation involved:

- Casting: Melting and shaping materials into desired forms.

- Machining: Removing material from a workpiece to create precise shapes.

- Forming: Changing the shape of materials without removing material.

- Joining: Combining separate components into a single unit.

- Assembly: Putting together components to create a final product.

The choice of manufacturing process depends on factors such as product design, material properties, production volume, and cost constraints.

4. How do you optimize production schedules to maximize efficiency and minimize costs?

Production scheduling involves planning and sequencing production activities to meet customer demand efficiently and cost-effectively. Optimization techniques include:

- Linear programming: Mathematical models to determine the optimal production plan based on constraints and objectives.

- Heuristics and simulation: Iterative methods and computer simulations to find near-optimal solutions in complex systems.

- Just-in-time (JIT) manufacturing: Minimizing waste and inventory by producing only what is needed, when it is needed.

Optimization involves balancing factors such as setup times, production capacity, lead times, and material availability.

5. How do you handle quality control and assurance in a manufacturing system?

Quality control and assurance are crucial for maintaining product quality and customer satisfaction. Measures include:

- Establishing quality standards and specifications.

- Conducting inspections and tests at various stages of production.

- Implementing statistical process control (SPC) to monitor and adjust processes.

- Adopting quality management systems such as Six Sigma or ISO 9001.

- Empowering employees to take ownership of quality.

6. Discuss the role of automation and robotics in modern manufacturing systems.

Automation and robotics play a significant role in enhancing productivity, accuracy, and efficiency in manufacturing:

- Automated machines: Programmable devices used for repetitive tasks, such as assembly, packaging, and welding.

- Industrial robots: Advanced machines with multiple degrees of freedom, used for complex tasks, such as welding, painting, and assembly.

- Computer-aided manufacturing (CAM): Software that controls and monitors automated machines.

Implementing automation requires careful planning, integration, and maintenance to maximize benefits.

7. How do you evaluate the performance of a manufacturing system?

Manufacturing system performance can be assessed using various metrics:

- Productivity: Output produced per unit of input.

- Efficiency: Ratio of actual output to theoretical maximum output.

- Quality: Conformance to specifications and customer requirements.

- Lead time: Time from order placement to product delivery.

- Inventory levels: Amount of raw materials, work-in-progress, and finished goods on hand.

Benchmarking against industry standards and conducting regular performance audits help identify areas for improvement.

8. What are the emerging trends and technologies in manufacturing systems engineering?

- Industry 4.0: Integration of digital technologies, such as IoT, big data, and artificial intelligence.

- Additive manufacturing (3D printing): Creating complex objects by adding materials layer by layer.

- Sustainable manufacturing: Minimizing environmental impact and promoting resource efficiency.

- Collaborative robots (cobots): Robots designed to work alongside human workers.

- Cloud-based manufacturing: Accessing and managing manufacturing data and services remotely.

9. How do you stay updated with the latest advancements in manufacturing systems engineering?

- Attending conferences and industry events.

- Reading technical journals and research papers.

- Participating in online forums and communities.

- Engaging in continuing education and professional development programs.

- Networking with other professionals in the field.

10. Describe a challenging project you worked on in manufacturing systems engineering and how you overcame the challenges.

In a recent project, we faced the challenge of designing and implementing an automated assembly line for a new product. The line required complex coordination between multiple machines and robots. We overcame the challenge by:

- Conducting detailed simulations to optimize the line layout and minimize downtime.

- Developing custom software to integrate the different machines and control the overall system.

- Training operators thoroughly on the new equipment and processes.

- Establishing a continuous improvement process to monitor performance and identify areas for optimization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manufacturing Systems Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manufacturing Systems Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Manufacturing Systems Engineers are responsible for the design, implementation, and maintenance of manufacturing systems. They work with other engineers, technicians, and production staff to improve the efficiency and productivity of manufacturing processes.

1. Design and Implement Manufacturing Systems

Manufacturing Systems Engineers design and implement new manufacturing systems or modify existing systems to improve efficiency. They work with other engineers and technicians to select the appropriate equipment and processes for the system. They also develop and implement quality control procedures to ensure that products meet specifications.

- Design and implement new manufacturing systems or modify existing systems to improve efficiency.

- Work with other engineers and technicians to select the appropriate equipment and processes for the system.

- Develop and implement quality control procedures to ensure that products meet specifications.

2. Analyze and Improve Manufacturing Processes

Manufacturing Systems Engineers analyze manufacturing processes to identify areas for improvement. They use data analysis techniques to identify bottlenecks and inefficiencies. They then develop and implement solutions to improve the process. They also work with other engineers and technicians to identify and implement new technologies to improve manufacturing processes.

- Analyze manufacturing processes to identify areas for improvement.

- Use data analysis techniques to identify bottlenecks and inefficiencies.

- Develop and implement solutions to improve the process.

- Work with other engineers and technicians to identify and implement new technologies to improve manufacturing processes.

3. Manage and Maintain Manufacturing Systems

Manufacturing Systems Engineers manage and maintain manufacturing systems. They ensure that systems are operating efficiently and safely. They also troubleshoot and repair problems. They work with other engineers and technicians to develop and implement maintenance schedules. They also work with production staff to train them on how to operate and maintain the systems.

- Manage and maintain manufacturing systems.

- Ensure that systems are operating efficiently and safely.

- Troubleshoot and repair problems.

- Work with other engineers and technicians to develop and implement maintenance schedules.

- Work with production staff to train them on how to operate and maintain the systems.

4. Collaborate with Other Teams

Manufacturing Systems Engineers collaborate with other teams within the organization, such as production, engineering, and quality control. They share information and expertise to improve the overall manufacturing process. They also work with suppliers and customers to ensure that the manufacturing system meets their needs.

- Collaborate with other teams within the organization, such as production, engineering, and quality control.

- Share information and expertise to improve the overall manufacturing process.

- Work with suppliers and customers to ensure that the manufacturing system meets their needs.

Interview Tips

Preparing for an interview for a Manufacturing Systems Engineer position requires a combination of technical knowledge and an understanding of the industry. Here are some tips to help you ace your interview:

1. Research the Company and the Role

Before the interview, take some time to research the company and the specific role you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the specific requirements of the role.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read industry news and articles to learn about the latest trends and challenges in the manufacturing industry.

- Prepare questions to ask the interviewer about the company, the role, and the team you will be working with.

2. Highlight Your Technical Skills

Manufacturing Systems Engineers need to have a strong foundation in engineering principles. Be sure to highlight your technical skills during the interview. Discuss your experience with designing, implementing, and maintaining manufacturing systems. Also, be prepared to answer questions about your knowledge of specific manufacturing processes and technologies.

- Quantify your accomplishments whenever possible. For example, instead of saying “I improved the efficiency of the manufacturing process,” you could say “I improved the efficiency of the manufacturing process by 15%, resulting in a cost savings of $1 million per year.”

- Be prepared to discuss your experience with specific manufacturing software and tools.

- If you have any experience with lean manufacturing or other quality improvement methodologies, be sure to mention it.

3. Emphasize Your Problem-Solving Skills

Manufacturing Systems Engineers need to be able to solve problems quickly and efficiently. During the interview, be sure to emphasize your problem-solving skills. Discuss your experience with troubleshooting and resolving manufacturing problems. Also, be prepared to answer questions about how you would approach specific manufacturing challenges.

- Use the STAR method to answer questions about your problem-solving experience. STAR stands for Situation, Task, Action, Result.

- For example, you could say “I was working on a manufacturing line that was experiencing a lot of downtime. I analyzed the problem and identified the root cause. I then developed a solution that reduced downtime by 50%.”

4. Demonstrate Your Communication and Teamwork Skills

Manufacturing Systems Engineers need to be able to communicate effectively with a variety of stakeholders, including engineers, technicians, production staff, and customers. During the interview, be sure to demonstrate your communication and teamwork skills. Discuss your experience with working on cross-functional teams and with communicating technical information to non-technical audiences.

- Use specific examples to illustrate your communication and teamwork skills.

- For example, you could say “I worked on a team that was responsible for developing a new manufacturing process. I was responsible for communicating the process to the production staff. I developed a training program that was clear and easy to follow. As a result, the production staff was able to quickly learn the new process and begin using it effectively.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Manufacturing Systems Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!