Feeling lost in a sea of interview questions? Landed that dream interview for Pipe Coverer Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pipe Coverer Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

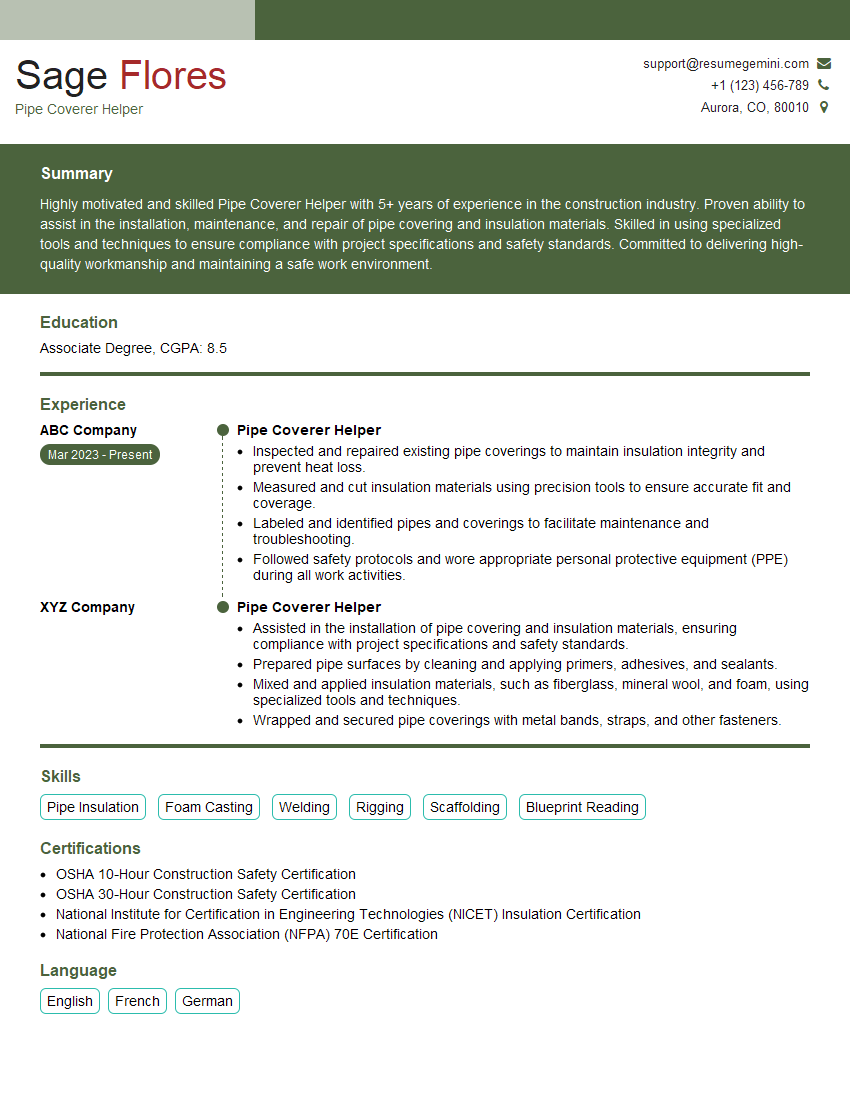

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Coverer Helper

1. Describe the different types of insulations you have worked with?

In my previous role, I have experience working with various types of insulation, including:

- Fiberglass insulation: It is commonly used in residential and commercial buildings due to its cost-effectiveness and ease of installation.

- Rigid foam insulation: It provides excellent thermal resistance and is often used in exterior walls and roofs.

- Cellular insulation: It has closed-cell or open-cell structure and offers good insulation value and moisture resistance.

- Mineral wool insulation: Made from natural materials like rock or slag, it provides acoustic insulation and fire resistance.

2. How do you calculate the amount of insulation needed for a specific project?

Surface area calculation

- Measure the length and width of the surfaces to be insulated.

- Multiply the length and width to get the surface area in square feet.

Insulation thickness

- Determine the recommended insulation thickness based on local building codes and energy efficiency standards.

Total insulation required

- Multiply the surface area by the insulation thickness to get the total volume of insulation needed in cubic feet.

3. What safety precautions should be taken when working with insulation?

To ensure safety when working with insulation, I adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE) like gloves, safety glasses, and a dust mask to minimize exposure to irritants.

- Handle insulation carefully to avoid creating excessive dust and fibers.

- Ensure proper ventilation in the workspace to prevent the buildup of insulation particles in the air.

- Be aware of sharp edges on insulation materials and use proper cutting tools.

- Follow manufacturer’s instructions for handling and storage of insulation to maintain its integrity and effectiveness.

4. How do you install insulation on pipes?

To install insulation on pipes, I typically follow these steps:

- Prepare the pipe surface by cleaning and removing any dirt or debris.

- Measure and cut the insulation to the appropriate length and shape.

- Apply adhesive or use mechanical fasteners to secure the insulation to the pipe.

- Overlapping the insulation joints to prevent heat loss.

- Seal the joints and any gaps using tape or mastic to ensure a tight fit.

- Protect the insulation from moisture and damage by wrapping it with a vapor barrier or jacketing.

5. What tools are commonly used by a Pipe Coverer Helper?

As a Pipe Coverer Helper, I am familiar with using a range of tools, including:

- Measuring tape for accurate measurements.

- Utility knife or scissors for cutting insulation.

- Adhesive or mechanical fasteners for securing insulation.

- Gloves and safety glasses for protection.

- Hand tools like pliers, wrenches, and screwdrivers.

- Insulation stapler or wire ties for additional reinforcement.

- Vapor barrier tape or mastic for sealing joints.

6. How do you maintain the quality of insulation over time?

To maintain the quality of insulation over time, I prioritize the following practices:

- Regular inspection of the insulation to identify any damage or deterioration.

- Prompt repair or replacement of damaged insulation to prevent heat loss and energy waste.

- Protection of insulation from moisture and physical damage by using appropriate jacketing or coverings.

- Adherence to manufacturer’s guidelines and industry best practices for installation and maintenance.

- Proper storage of insulation materials to prevent moisture absorption and contamination.

7. What are some common challenges you have faced as a Pipe Coverer Helper and how did you overcome them?

In my experience as a Pipe Coverer Helper, I have encountered various challenges, including:

- Dealing with tight or awkward spaces: I carefully plan the installation process and use appropriate tools and techniques to work effectively in confined areas.

- Working with different insulation materials: I familiarize myself with the properties and handling requirements of each insulation type to ensure proper installation and performance.

- Meeting project deadlines: I prioritize efficient time management and coordinate with other team members to complete tasks on schedule while maintaining quality.

- Ensuring safety: I am committed to following safety protocols and using proper PPE to minimize risks and maintain a safe work environment.

8. How do you stay up-to-date with the latest industry standards and best practices for insulation?

To stay current with industry advancements, I actively engage in the following practices:

- Attending industry conferences and workshops to learn about new technologies and techniques.

- Reading trade publications and articles to keep abreast of industry trends and best practices.

- Participating in online forums and discussions to connect with other professionals and exchange knowledge.

- Seeking guidance from experienced mentors and colleagues to gain valuable insights.

9. Tell me about a time when you had to work independently and solve a problem on a pipe covering project?

In a previous project, I encountered an issue where the insulation on a section of piping was damaged during installation. I assessed the situation and determined that the damage could compromise the insulation’s effectiveness. To resolve the issue independently, I:

- Removed the damaged insulation carefully without further damaging the pipe.

- Measured and cut a new piece of insulation to the exact dimensions.

- Applied adhesive and secured the new insulation to the pipe, ensuring a tight fit.

- Inspected the repair to ensure it met the required standards and performance.

10. Why are you interested in working as a Pipe Coverer Helper for our company?

I am eager to join your company as a Pipe Coverer Helper because I am impressed by your commitment to providing high-quality insulation solutions and your reputation for industry excellence. I believe that my skills and experience in insulation installation, maintenance, and safety would be a valuable asset to your team. Moreover, I am excited about the opportunity to contribute to your company’s success and growth in the insulation industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Coverer Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Coverer Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pipe Coverer Helper is responsible for assisting a Pipe Coverer in insulating and sealing pipes and vessels in various industrial settings. Their key responsibilities include:

1. Assisting with Pipe Insulation

Assisting the Pipe Coverer in measuring, cutting, and installing insulation materials such as fiberglass, mineral wool, and cellular glass on pipes and vessels.

- Preparing insulation materials by cutting them to the required size and shape.

- Applying adhesives and other materials to adhere insulation to pipes.

2. Handling Materials

Handling and moving heavy materials such as insulation rolls, adhesives, and sealants.

- Loading and unloading materials from trucks and storage areas.

- Transporting materials to the job site and handling them safely.

3. Maintaining Work Area

Maintaining a clean and organized work area by disposing of debris and waste materials.

- Sweeping or vacuuming work areas to remove insulation particles and other debris.

- Ensuring proper storage of materials and equipment.

4. Safety Compliance

Adhering to all safety regulations and procedures to maintain a safe work environment.

- Wearing appropriate personal protective equipment (PPE).

- Following proper handling and storage techniques for materials.

Interview Tips

To ace an interview for a Pipe Coverer Helper position, consider the following tips:

1. Research the Company and Position

Gather information about the company’s industry, values, and the specific responsibilities of the Pipe Coverer Helper role. This will help you understand the company’s needs and demonstrate your interest in the position.

- Visit the company’s website and social media pages.

- Review industry publications and news articles.

2. Highlight Relevant Skills and Experience

Emphasize your physical strength, ability to handle heavy materials, and attention to detail. If you have any prior experience in construction or insulation, be sure to mention it.

- Quantify your accomplishments with specific examples.

- Use action verbs to describe your responsibilities.

3. Demonstrate Safety Awareness

Convey your understanding of safety protocols and your commitment to maintaining a safe work environment. Explain your experiences with PPE and material handling.

- Share examples of how you have followed safety regulations in previous roles.

- Express your willingness to undergo any necessary safety training.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions about the company’s growth plans, the work environment, and opportunities for professional development.

- Research common interview questions and prepare answers accordingly.

- Practice your answers to improve your delivery and confidence.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pipe Coverer Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.