Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Core Driller Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

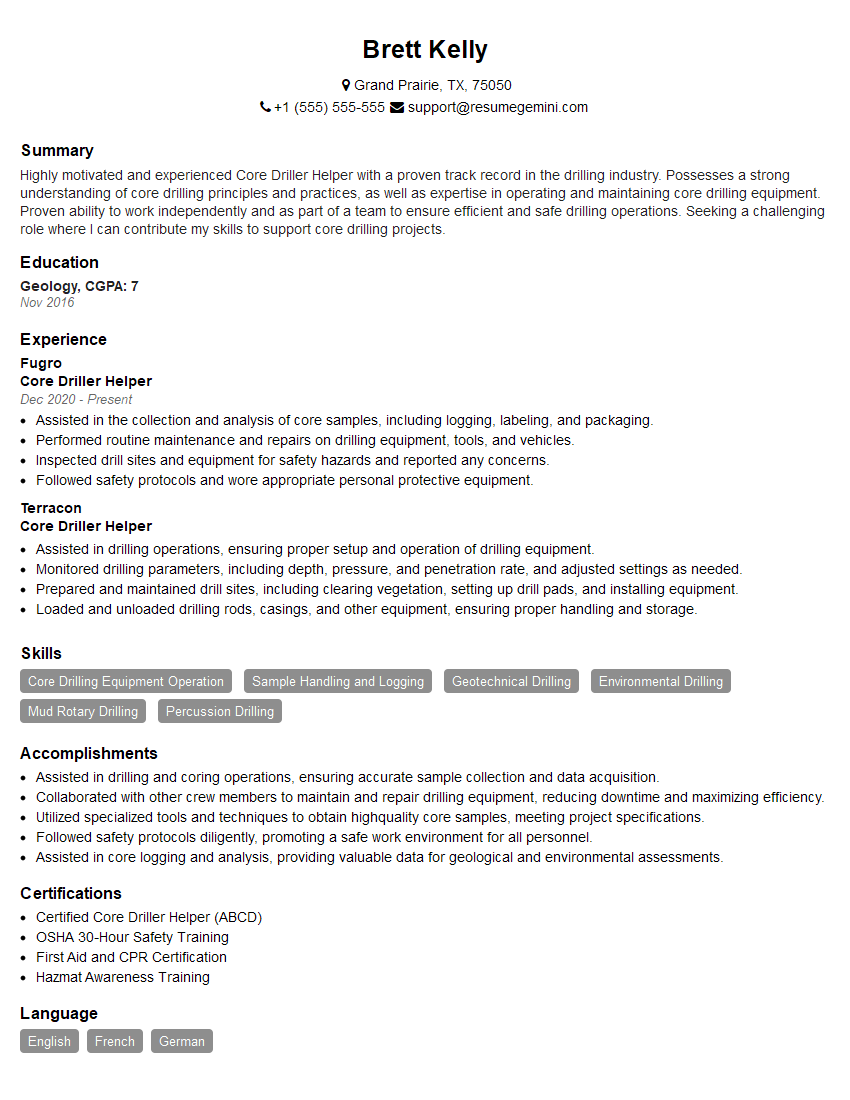

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Core Driller Helper

1. What is the purpose of a core drilling rig?

A core drilling rig is used to extract cylindrical samples of rock, soil, or other materials from the ground. These samples are used for a variety of purposes, including geological surveys, mineral exploration, and construction site investigations.

2. What are the different types of core drilling rigs?

There are two main types of core drilling rigs: rotary rigs and percussion rigs.

Rotary rigs

- Use a rotating bit to cut through the material.

- Are typically used for drilling in soft to medium-hard materials, such as soil, sand, and clay.

Percussion rigs

- Use a hammer to drive a bit into the material.

- Are typically used for drilling in hard materials, such as rock and concrete.

3. What are the key components of a core drilling rig?

The key components of a core drilling rig include:

- The drill head, which houses the bit and rotates it.

- The drill string, which is made up of sections of pipe that are connected together and rotated by the drill head.

- The core barrel, which is attached to the bottom of the drill string and collects the core samples.

- The mud pump, which circulates drilling fluid through the drill string and core barrel to cool and lubricate the bit and remove cuttings.

4. What are the different types of core bits?

There are a variety of different types of core bits, each designed for a specific type of material. The most common types of core bits include:

- Diamond bits: Used for drilling in hard materials, such as rock and concrete.

- Carbide bits: Used for drilling in medium-hard materials, such as soil and sand.

- Tricone bits: Used for drilling in soft materials, such as clay and silt.

5. What are the safety precautions that must be taken when operating a core drilling rig?

When operating a core drilling rig, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a hard hat.

- Inspect the rig and all of its components before each use.

- Make sure the rig is properly set up and leveled.

- Never operate the rig under the influence of alcohol or drugs.

- Be aware of your surroundings and keep clear of the drill head and other moving parts.

6. What are the different types of drilling fluids?

There are a variety of different types of drilling fluids, each with its own unique properties. The most common types of drilling fluids include:

- Water-based drilling fluids: Used for drilling in soft to medium-hard materials.

- Oil-based drilling fluids: Used for drilling in hard materials and in areas where water-based drilling fluids are not suitable.

- Air drilling fluids: Used for drilling in dry or dusty conditions.

7. What are the different methods of core drilling?

There are two main methods of core drilling: wet drilling and dry drilling.

Wet drilling

- Uses a drilling fluid to cool and lubricate the bit and remove cuttings.

- Is typically used for drilling in soft to medium-hard materials.

Dry drilling

- Does not use a drilling fluid.

- Is typically used for drilling in hard materials.

8. What are the different applications of core drilling?

Core drilling is used in a variety of applications, including:

- Geological surveys

- Mineral exploration

- Construction site investigations

- Geotechnical engineering

- Environmental site assessments

9. What are the challenges of core drilling?

Core drilling can be a challenging process, depending on the material being drilled and the conditions at the site. Some of the challenges of core drilling include:

- Drilling in hard materials

- Drilling in wet or unstable conditions

- Drilling in areas with limited access

- Ensuring the accuracy and quality of the core samples

10. What are the career opportunities for core drilling helpers?

Core drilling helpers can advance their careers by gaining experience and training. They can become core drillers, who are responsible for operating core drilling rigs. Core drillers can also become supervisors or managers, who are responsible for overseeing core drilling operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Core Driller Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Core Driller Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Core Drillers are responsible for the operation of drilling equipment used to extract cylindrical samples from geological formations. Core Drillers typically work with other crew members in the field to operate and maintain drilling machines. Their primary responsibility is to assist in the drilling process by performing tasks such as setting up and breaking down drilling equipment, mixing drilling fluids, and handling and storing core samples. Core Drillers must be able to work effectively as part of a team and be able to lift heavy objects.Under the supervision of a Core Driller, a Core Driller Helper will assist in the following activities:

1. Drilling Operations

Assist in the assembly, transportation, maintenance and operation of the drilling machine.

- Load and unload drill rods, casing, and other equipment.

- Set up and operate drilling equipment, including pumps, compressors, and generators.

- Monitor drilling progress and make adjustments as needed.

2. Mud Handling

Prepare, maintain and monitor drilling fluids, including mixing, recycling and disposal.

- Operate pumps, valves, and other equipment used to circulate drilling fluids.

- Monitor fluid levels and make adjustments as needed.

3. Core Handling

Handle and store core samples, including labeling, packaging, and transportation.

- Remove core samples from the drill hole.

- Cut and prepare core samples for analysis.

4. Safety

Follow all safety protocols and procedures, including wearing personal protective equipment (PPE).

- Maintain a clean and organized work area.

- Report any accidents or injuries immediately.

Interview Tips

Preparing adequately for an interview is a vital part of the application process. Here are some tips to help you ace your interview for a Core Driller Helper position.

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company and the specific position you are applying for. This will demonstrate your enthusiasm and interest in the role and the company.

- Visit the company’s website and social media pages to learn about their culture, values, and recent projects.

- Read job descriptions carefully and identify the key skills and qualifications required for the position.

2. Practice Answering Common Interview Questions

There are certain questions that are commonly asked in interviews for Core Driller Helper positions. By preparing for these questions in advance, you can feel more confident and articulate during the interview. Here are some questions to practice:

- Tell me about your experience working on a drilling crew.

- What are the safety protocols you follow when working on a drill site?

- What is your experience with handling and storing core samples?

- How do you maintain and operate drilling equipment?

3. Be Enthusiastic and Professional

Throughout the interview, it is important to maintain a positive and enthusiastic attitude. Show the interviewer that you are passionate about the role and the industry.

- Be polite and respectful to everyone you encounter.

- Make eye contact with the interviewer and actively listen to their questions.

4. Ask Questions

At the end of the interview, it is customary for the interviewer to ask if you have any questions. This is your opportunity to learn more about the position, the company, and the next steps in the hiring process.

- Prepare a few thoughtful questions to ask the interviewer.

- This demonstrates your interest and engagement in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Core Driller Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!