Feeling lost in a sea of interview questions? Landed that dream interview for Structural Steel Worker Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Structural Steel Worker Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

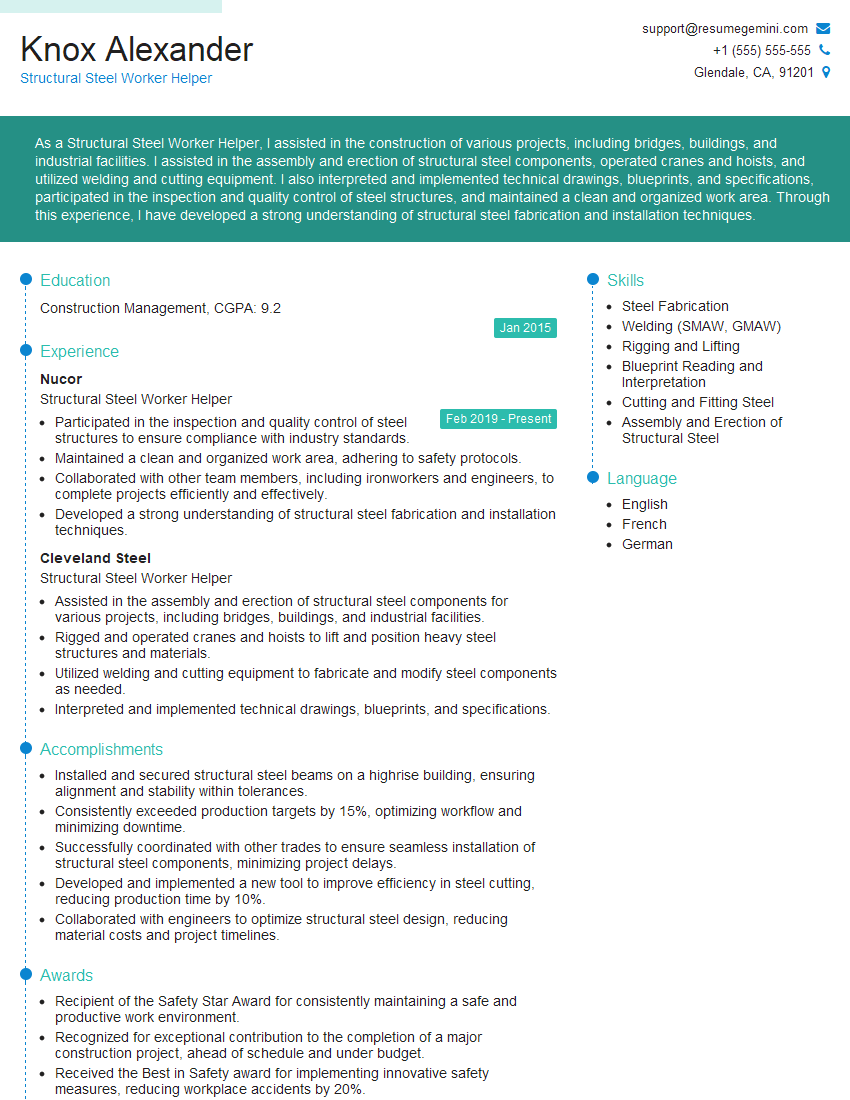

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Structural Steel Worker Helper

1. What are the different types of structural steel used in construction?

There are various types of structural steel utilized in construction, including:

- Carbon Steel: Common type of structural steel, known for its strength and durability.

- Alloy Steel: Enhanced with alloying elements like chromium, nickel, or molybdenum, improving strength and toughness.

- Stainless Steel: Corrosion-resistant, making it suitable for applications requiring durability and aesthetics.

- High-Strength Steel: Possesses a higher yield strength than conventional steel, allowing for lighter and more efficient structures.

2. Describe the different welding processes used in structural steel fabrication.

Arc Welding:

- Shielded Metal Arc Welding (SMAW): Manual process using consumable electrodes.

- Gas Metal Arc Welding (GMAW): Semi-automatic process using shielding gas and continuously fed wire electrode.

- Gas Tungsten Arc Welding (GTAW): Manual process using a non-consumable tungsten electrode and shielding gas.

Resistance Welding:

- Spot Welding: Joining metal sheets by applying heat and pressure at specific points.

- Projection Welding: Welds metal sheets by joining pre-formed projections.

3. What are the key steps involved in erecting structural steel frames?

The key steps in erecting structural steel frames typically include:

- Preparation: Site preparation, layout, and foundation work.

- Steel Erection: Lifting and positioning steel beams, columns, and other components.

- Bolting and Welding: Connecting steel members using bolts or welding.

- Alignment and Leveling: Ensuring proper alignment and leveling of the structure.

- Inspection and Documentation: Verifying the quality of the erection and documenting the process.

4. How do you ensure the safety of yourself and others while working with structural steel?

To ensure safety while working with structural steel, I prioritize the following measures:

- Proper Safety Gear: Wearing appropriate personal protective equipment (PPE), including hard hat, safety glasses, gloves, and steel-toed boots.

- Risk Assessment: Identifying and mitigating potential hazards before starting work.

- Safe Lifting Techniques: Using proper lifting equipment and techniques to prevent injuries.

- Communication and Coordination: Maintaining effective communication with team members and following established safety protocols.

- Regular Training and Inspections: Participating in safety training programs and conducting regular inspections of equipment and the work area.

5. What is the importance of proper storage and handling of structural steel?

Proper storage and handling of structural steel are crucial for several reasons:

- Maintaining Quality: Protecting steel from damage, rust, and corrosion to ensure its integrity and performance.

- Preventing Accidents: Properly stored and handled steel minimizes the risk of accidents or injuries during transportation and installation.

- Safety Regulations: Adhering to industry regulations and safety guidelines for storing and handling structural steel.

6. Describe the different types of bolts and fasteners used in structural steel connections.

- High-Strength Bolts: These bolts are designed to withstand high loads and are commonly used in critical structural connections.

- Shear Bolts: Used to resist shear forces in connections, such as those found in beam-to-column joints.

- Rivets: Traditional method of connecting structural steel, but less common now due to their labor-intensive installation process.

- Welds: Welds provide a strong and permanent connection between steel members, eliminating the need for bolts or rivets.

7. What are the common causes of structural steel failure?

- Overloading: Exceeding the design capacity of the structure.

- Corrosion: Rust and other forms of corrosion can weaken steel over time.

- Brittle Fracture: Sudden and catastrophic failure due to low toughness or defects in the steel.

- Fatigue: Repeated loading and unloading can cause cracks to develop and eventually lead to failure.

- Design Errors: Errors in structural design or analysis can result in inadequate strength or stability.

8. What are the key factors to consider when selecting a structural steel supplier?

- Reputation and Experience: Choosing a reputable supplier with a proven track record in the industry.

- Product Quality: Ensuring the supplier meets industry standards and provides high-quality steel.

- Delivery and Logistics: Considering the supplier’s ability to deliver materials on time and to the specified location.

- Technical Support: Seeking a supplier who provides technical support and assistance with product selection and design.

- Cost and Value: Balancing the cost of materials with the value and reliability they provide.

9. How do you stay updated with the latest advancements and best practices in the structural steel industry?

- Industry Conferences and Events: Attending industry events and conferences to learn about new technologies and trends.

- Trade Publications: Reading industry magazines and journals to stay informed about best practices and innovations.

- Professional Development: Seeking opportunities for continuing education and professional development courses.

- Networking: Connecting with industry professionals and sharing knowledge through professional organizations.

- Research and Innovation: Engaging in research and exploring new ideas to improve structural steel construction methods.

10. What is your experience in working with drawings and blueprints for structural steel fabrication?

Throughout my career, I have developed strong proficiency in reading and interpreting drawings and blueprints for structural steel fabrication. I am familiar with various industry-standard drawing conventions and can accurately extract information such as dimensions, tolerances, and material specifications from technical drawings.

- Understanding Structural Symbols: I am well-versed in structural symbols and notations used in drawings, enabling me to comprehend complex design details.

- Material Identification: I can accurately identify different steel grades, shapes, and sizes based on the information provided in the drawings.

- Fabrication Interpretation: I am skilled in understanding the fabrication sequence and requirements specified in the drawings.

- Quality Control: I use drawings to verify dimensions, tolerances, and other quality control parameters during the fabrication process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Structural Steel Worker Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Structural Steel Worker Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Structural Steel Worker Helpers support the fabrication and assembly of structural steel components for construction projects. Key responsibilities include:

1. Assist in Fabrication

Mark, cut, and shape steel beams, plates, and other components using power tools and hand tools.

- Operate machinery, such as saws, grinders, and drills.

- Weld and assemble steel components following blueprints and design specifications.

2. Support Construction

Assist in erecting and aligning steel beams, columns, and other structural members.

- Bolt and weld components together to form sturdy structures.

- Operate cranes and other equipment to lift and position heavy steel components.

3. Inspect and Maintain

Inspect fabricated steel components for defects and ensure they meet quality standards.

- Monitor work areas and equipment for safety and cleanliness.

- Follow all safety protocols and regulations.

4. Cleaning and Maintenance

Clean and maintain work areas, tools, and equipment.

- Dispose of waste materials properly.

- Perform minor repairs and maintenance tasks.

Interview Tips

To ace the interview for a Structural Steel Worker Helper position, consider the following tips:

1. Research the Company and Industry

Learn about the company’s history, projects, and safety record. Familiarize yourself with the latest industry trends and technologies.

- Visit the company’s website and social media pages.

- Read recent articles and news stories about the structural steel industry.

2. Highlight Relevant Skills and Experience

Emphasize your experience in fabrication, assembly, and welding. Quantify your accomplishments and provide specific examples of your work.

- Use action verbs and specific details to describe your responsibilities.

- Mention any certifications or training programs you have completed.

3. Demonstrate Safety Awareness

Structural steel work involves hazardous materials and machinery. Show the interviewer that you prioritize safety by emphasizing your knowledge of safety protocols.

- Explain how you ensure your own safety and the safety of others on the job site.

- Describe your experience with personal protective equipment (PPE).

4. Prepare for Common Interview Questions

Review common interview questions related to the job responsibilities and qualifications. Practice answering them clearly and confidently.

- Examples: “Why are you interested in working as a Structural Steel Worker Helper?” and “Describe a time when you worked safely on a construction project.”

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

5. Ask Thoughtful Questions

Show that you’re engaged and interested by asking thoughtful questions about the company, the role, and the industry.

- Examples: “What are the company’s plans for future growth in the structural steel industry?” or “What opportunities are there for professional development within the company?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Structural Steel Worker Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.