Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pressure Vessel Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pressure Vessel Inspector so you can tailor your answers to impress potential employers.

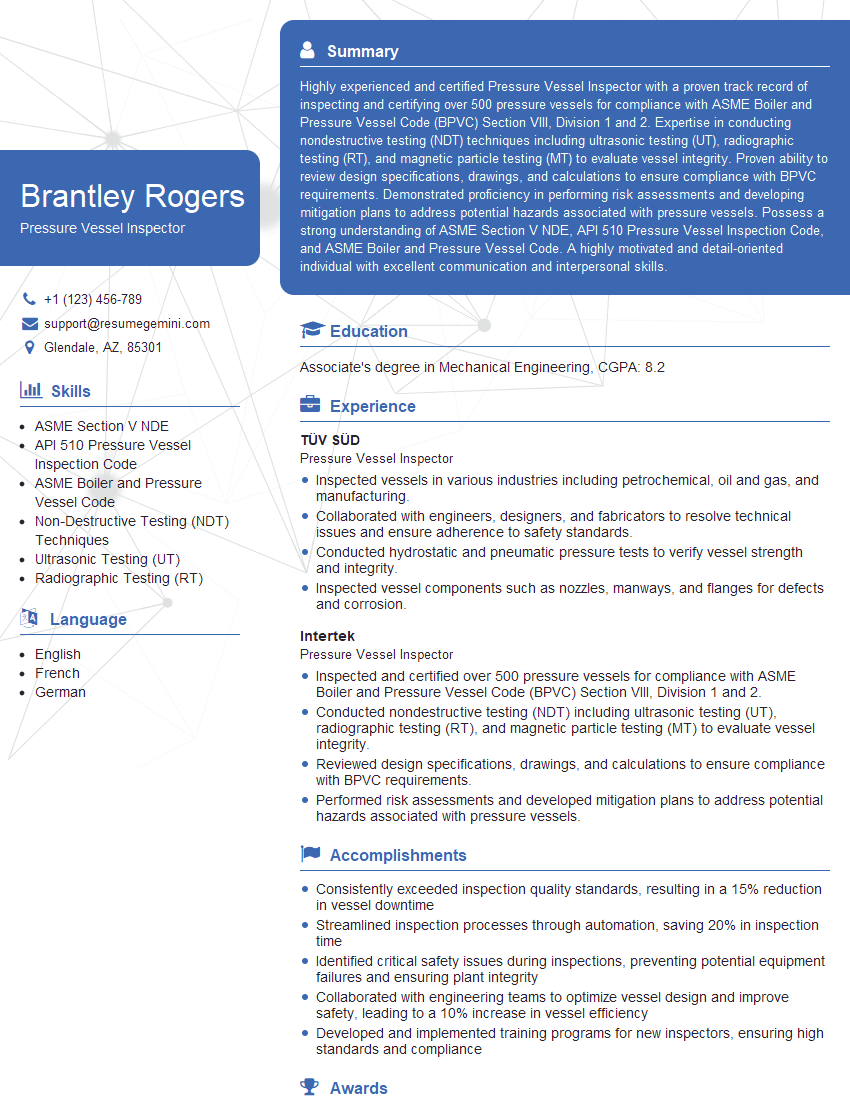

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pressure Vessel Inspector

1. What are the common types of pressure vessels and their respective applications?

- Storage vessels: Used for storing gases or liquids under pressure, such as tanks, cylinders, and spheres.

- Process vessels: Used in chemical, oil and gas, and pharmaceutical industries for various processes, such as reactors, boilers, and autoclaves.

- Transportation vessels: Designed to transport gases or liquids under pressure, such as tanker trucks and rail cars.

- Specialized vessels: Used for specific applications, such as nuclear reactors, rocket engines, and deep-sea exploration.

2. Describe the key components of a pressure vessel and their functions.

Vessel Shell

- Primary pressure boundary

- Withstands internal pressure and external loads

Heads

- Seal the ends of the vessel

- Transfer pressure to the shell

Nozzles

- Openings for connections

- Must be designed to minimize stress concentrations

Flanges

- Connect nozzles to pipes or other components

- Provide a leak-proof seal

3. Explain the different types of materials used in the construction of pressure vessels and their advantages and disadvantages.

- Carbon steel: Low cost, high strength, but susceptible to corrosion.

- Alloy steels: Enhanced strength and corrosion resistance, but more expensive.

- Stainless steel: Excellent corrosion resistance, but higher cost and lower strength.

- Aluminum alloys: Lightweight and corrosion-resistant, but lower strength and higher cost.

- Nickel alloys: High strength and corrosion resistance, but very expensive.

4. What are the main codes and standards that govern the design and inspection of pressure vessels?

- ASME Boiler and Pressure Vessel Code (BPVC)

- National Board Inspection Code (NBIC)

- European Standard EN 13445

- API Standard 510

- ASME PCC-2 Repair Code

5. What is the purpose of a pressure vessel inspection and what are the key areas to be examined?

Purpose:

- Ensure the safe operation of pressure vessels

- Identify potential hazards

- Assess the condition of the vessel

- Determine compliance with codes and standards

Key Areas:

- Vessel shell

- Heads

- Nozzles

- Flanges

- Bolting

- Welding

- Safety devices

6. How do you determine the maximum allowable working pressure (MAWP) of a pressure vessel?

- Refer to the design code (e.g., ASME BPVC Section VIII)

- Consider the material properties, thickness, and design temperature

- Calculate the maximum allowable stress using formulas provided in the code

- Use the calculated stress and vessel geometry to determine the MAWP

7. What are the common methods of non-destructive testing (NDT) used in pressure vessel inspections?

- Visual inspection (VT)

- Magnetic particle testing (MT)

- Dye penetrant testing (PT)

- Ultrasonic testing (UT)

- Radiographic testing (RT)

8. Explain the process of hydrostatic testing of pressure vessels and its purpose.

- Purpose: Verify the integrity and strength of the vessel at a specified pressure.

- Process:

- Fill the vessel with water

- Gradually increase the pressure to the test pressure

- Hold the pressure for a specified period of time

- Monitor the vessel for any leaks or deformations

9. What are the different types of corrosion that can occur in pressure vessels and how can they be prevented?

- Uniform corrosion: Even thinning of the metal surface.

- Pitting corrosion: Localized areas of intense corrosion.

- Galvanic corrosion: Corrosion due to dissimilar metals in contact.

- Stress corrosion cracking: Corrosion at areas of high stress.

- Prevention:

- Use corrosion-resistant materials

- Apply protective coatings

- Implement cathodic protection

- Regular inspections and maintenance

10. How do you stay up-to-date on the latest industry standards and best practices for pressure vessel inspection?

- Attend industry conferences and workshops

- Read technical publications and journals

- Participate in professional organizations

- Obtain certifications and training

- Network with other professionals

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pressure Vessel Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pressure Vessel Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pressure Vessel Inspectors are responsible for ensuring the safety and integrity of pressure vessels, which are essential components in various industries, including oil and gas, chemical, and manufacturing.

1. Inspect and Certify Pressure Vessels

Conduct thorough inspections of pressure vessels, both internally and externally, to assess their condition and compliance with safety regulations.

- Review design specifications, drawings, and construction records

- Examine materials, welds, and other components for defects or damage

- Perform pressure tests and other non-destructive examinations to ensure vessel integrity

2. Issue Inspection Reports and Certificates

Prepare detailed inspection reports documenting findings, recommendations, and any necessary repairs or modifications.

- Issue inspection certificates based on compliance with applicable codes and standards

- Provide timely and clear communication of inspection results to clients and stakeholders

3. Enforce Safety Regulations and Standards

Ensure compliance with all relevant safety regulations, codes, and standards.

- Monitor industry best practices and stay updated with technological advancements

- Provide guidance and advice to clients on safe operation and maintenance of pressure vessels

- Participate in incident investigations and provide expert opinions

4. Collaborate with Engineers and Technicians

Work closely with engineers, technicians, and other stakeholders to ensure the safe design, fabrication, and operation of pressure vessels.

- Review engineering drawings and specifications

- Provide technical advice on inspection methods and equipment

- Participate in design and modification projects

Interview Tips

Preparing thoroughly for a Pressure Vessel Inspector interview is crucial for showcasing your qualifications and making a strong impression. Consider the following tips to enhance your chances of success:

1. Research the Company and Industry

Familiarize yourself with the company’s history, operations, and safety record.

- Understand the industry’s regulations, standards, and best practices

- Research recent industry news and developments

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience.

- Describe your experience in pressure vessel inspection and testing

- Explain your understanding of the relevant safety regulations and codes

- Share examples of your ability to identify and resolve potential safety hazards

3. Highlight Your Technical Skills

Emphasize your proficiency in inspection techniques, including non-destructive examination methods.

- Discuss your expertise in using specialized equipment and software

- Provide examples of your ability to interpret inspection results and make sound judgments

4. Showcase Your Communication and Interpersonal Skills

As a Pressure Vessel Inspector, you will need to communicate effectively with clients, engineers, and other stakeholders.

- Describe your ability to write clear and concise inspection reports

- Share examples of your experience in presenting inspection findings and recommendations

5. Prepare Questions for the Interviewers

Asking thoughtful questions shows that you are engaged and interested in the position.

- Inquire about the company’s safety culture and commitment to regulatory compliance

- Ask about opportunities for professional development and advancement

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pressure Vessel Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!