Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Printed Circuit Designer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

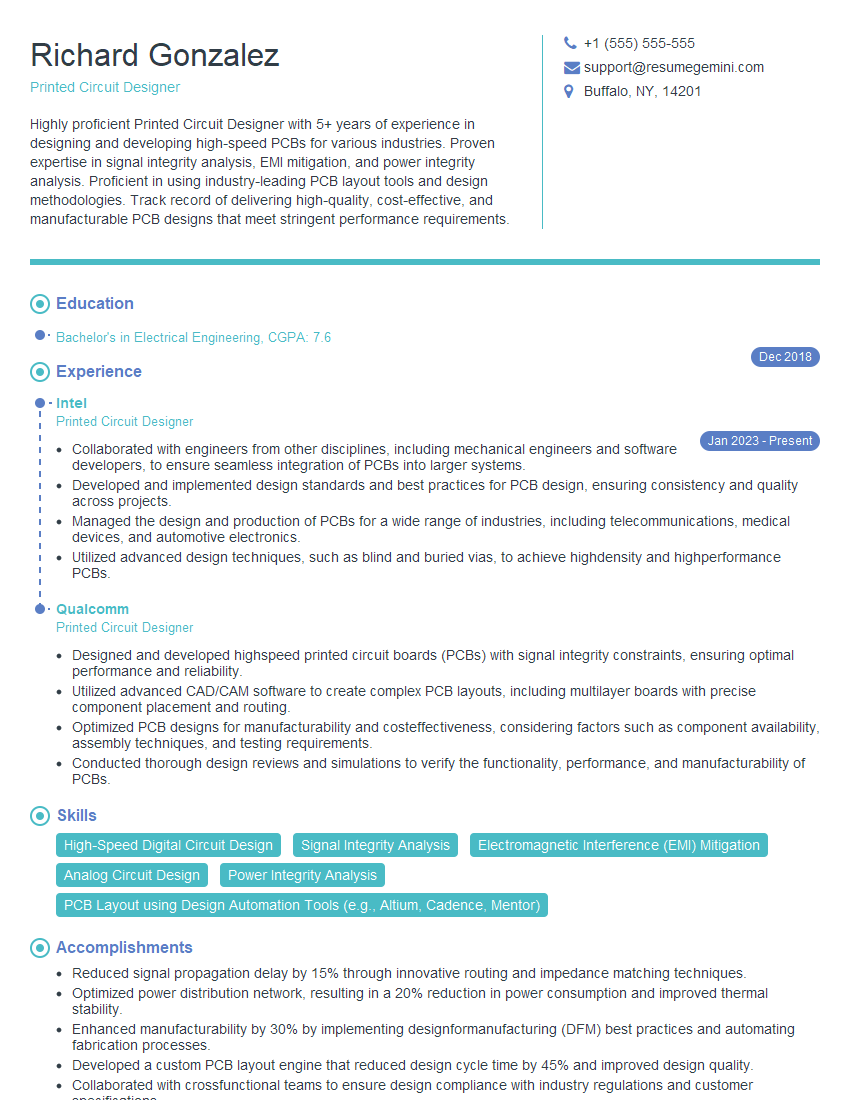

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Designer

1. Describe the design process you follow for creating a printed circuit board (PCB)?

The design process I follow for creating a PCB involves the following steps:

1. Conceptualization: I begin by understanding the functional requirements and specifications of the project.

2. Schematic design: I create a schematic diagram that represents the electrical connectivity and functionality of the circuit.

3. PCB layout: I use PCB design software to create the physical layout of the board, including component placement, routing, and layer stackup.

4. Design rule check (DRC): I perform DRC to ensure that the design meets the specified design rules and constraints.

5. Simulation: I conduct simulations to verify the functionality and performance of the design.

6. Fabrication: I generate the necessary files for fabrication and order the PCB from a manufacturer.

7. Assembly: I oversee the assembly of the PCB, ensuring proper component placement and soldering.

8. Testing: I conduct thorough testing to verify the functionality and performance of the assembled PCB.

2. What are the key considerations when designing a PCB for high-frequency applications?

Signal integrity

- Minimize signal losses by using appropriate trace widths and lengths.

- Control impedance to ensure signal fidelity.

- Reduce crosstalk between adjacent traces.

Power integrity

- Provide sufficient power and ground planes to reduce noise.

- Use decoupling capacitors to minimize voltage fluctuations.

- Properly route power and ground traces to avoid loops and ground bounce.

Thermal management

- Use heat sinks and thermal vias to dissipate heat from power components.

- Optimize airflow to prevent overheating.

- Consider using thermal modeling tools to analyze temperature distribution.

3. How do you ensure the manufacturability of your PCB designs?

- Follow industry design guidelines and standards.

- Use design for manufacturability (DFM) tools to identify potential manufacturing issues.

- Collaborate with the manufacturer to optimize the design for their specific capabilities.

- Design for testability (DFT) to facilitate easy testing and debugging.

- Use high-quality materials and components to ensure reliability.

4. Describe your experience with different types of PCB substrates.

I have experience working with a variety of PCB substrates, including:

1. FR-4: A general-purpose substrate with good mechanical and electrical properties.

2. Polyimide: A high-performance substrate with excellent thermal and chemical resistance.

3. Metal-clad PCB: A substrate with a metal layer that provides improved thermal conductivity and EMI shielding.

4. Rogers: A high-frequency substrate with low dielectric loss and controlled impedance.

5. Flexible PCB: A substrate that allows for bending and folding, suitable for applications where space is constrained.

5. How do you handle component placement and routing in a dense PCB design?

- Use automated placement and routing tools to optimize component placement and minimize trace lengths.

- Employ hierarchical routing techniques to organize and manage complex routing paths.

- Consider using multilayer boards to increase routing density.

- Prioritize critical signals and route them first to ensure optimal performance.

- Use differential routing for high-speed signals to reduce noise and improve signal integrity.

6. What are your preferred PCB design software tools?

My preferred PCB design software tools include:

1. Altium Designer: A comprehensive suite with powerful design, simulation, and manufacturing capabilities.

2. OrCAD: A user-friendly tool with a focus on schematic capture and simulation.

3. KiCad: An open-source software that offers a wide range of features and customization options.

4. Eagle: A popular tool for hobbyists and small-scale projects.

5. Proteus: A software that combines schematic capture, simulation, and PCB layout in a single platform.

7. How do you stay updated with the latest advancements in PCB design technology?

- Attend industry conferences and webinars.

- Read technical journals and articles.

- Participate in online forums and communities.

- Experiment with new software and design techniques.

- Collaborate with other PCB designers.

8. Describe a challenging PCB design project you have worked on and how you overcame the challenges.

Project:

Designing a high-frequency circuit board for a radar system that operates in the GHz range.Challenges:

- Meeting tight signal integrity and timing constraints.

- Accommodating a large number of components in a compact space.

- Ensuring proper thermal dissipation.

Solutions:

- Used controlled impedance routing and high-speed simulation to optimize signal transmission.

- Employed a multilayer design with careful component placement to minimize trace lengths and crosstalk.

- Utilized thermal vias and heat sinks to manage heat dissipation from power components.

9. How do you ensure the quality and reliability of your PCB designs?

- Follow industry standards and best practices.

- Conduct thorough design reviews and simulations.

- Use high-quality components and materials.

- Implement design for testability (DFT) features.

- Work closely with manufacturers to ensure proper fabrication and assembly.

10. What are your thoughts on the future of PCB design?

- Increased adoption of advanced materials and technologies, such as high-speed substrates and embedded components.

- Continued advancements in design software and simulation tools.

- Growing emphasis on design for manufacturability and testability.

- Integration of PCB design with other engineering disciplines, such as mechanical and thermal engineering.

- Increased use of artificial intelligence (AI) and machine learning (ML) to optimize design processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Designer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Designer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printed Circuit Designers (PCBs) are responsible for the design and development of printed circuit boards (PCBs), which are used in a wide range of electronic devices. Their primary responsibilities include:

1. Design and Development

Design and develop PCBs according to specifications and requirements. This involves creating schematics, layouts, and prototypes.

- Analyze and interpret design specifications to determine the functional requirements of the PCB.

- Select and place components on the PCB using computer-aided design (CAD) software, ensuring optimal performance and reliability.

2. Analysis and Simulation

Perform electrical and thermal analysis to ensure PCB functionality and performance. Optimize designs using simulation software.

- Conduct simulations to analyze the electrical behavior of the PCB, including current flow, voltage distribution, and electromagnetic interference.

- Identify and resolve potential design issues through simulation, reducing the need for costly physical prototyping.

3. Fabrication and Testing

Supervise PCB fabrication and assembly processes. Conduct testing and troubleshooting to ensure product quality.

- Work with manufacturers to ensure PCBs meet specifications and quality standards.

- Test and troubleshoot PCBs to identify and resolve any defects or performance issues.

4. Project Management

Manage PCB design projects from conception to completion. Collaborate with engineers, technicians, and other stakeholders.

- Establish project plans, timelines, and budgets for PCB design and development projects.

- Communicate effectively with clients, team members, and stakeholders to ensure project success.

Interview Tips

To help you ace your interview for a Printed Circuit Designer position, here are some essential tips and preparation strategies:

1. Research the Company and Role

Take the time to thoroughly research the company you are applying to and the specific role you are interviewing for. Understand their industry, products, and the responsibilities of the Printed Circuit Designer position within the organization.

- Visit the company website to learn about their mission, values, and recent projects.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies in PCB design.

2. Practice Your Technical Skills

PCB design involves a range of technical skills, so it’s crucial to practice and demonstrate your proficiency. Review your knowledge of PCB design software, such as Altium Designer or OrCAD, and be prepared to discuss your experience with specific design tools.

- Create a portfolio of your previous PCB designs to showcase your abilities.

- Practice answering technical questions related to PCB design principles, such as signal integrity, power distribution, and component placement.

3. Highlight Your Industry Knowledge

The electronics industry is constantly evolving, so it’s important to stay abreast of the latest advancements. Demonstrate your knowledge of industry trends, such as miniaturization, flexible PCBs, and high-speed design.

- Attend industry conferences and workshops to stay updated on emerging technologies.

- Read technical journals and articles to expand your understanding of PCB design.

4. Prepare for Behavioral Questions

In addition to technical questions, you can expect to be asked behavioral questions that assess your work style and personality. Prepare for questions about your problem-solving abilities, teamwork experience, and commitment to quality.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions effectively.

- Provide specific examples from your previous work experience that demonstrate your skills and qualities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printed Circuit Designer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.