Are you gearing up for a career in Castings Drafter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Castings Drafter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

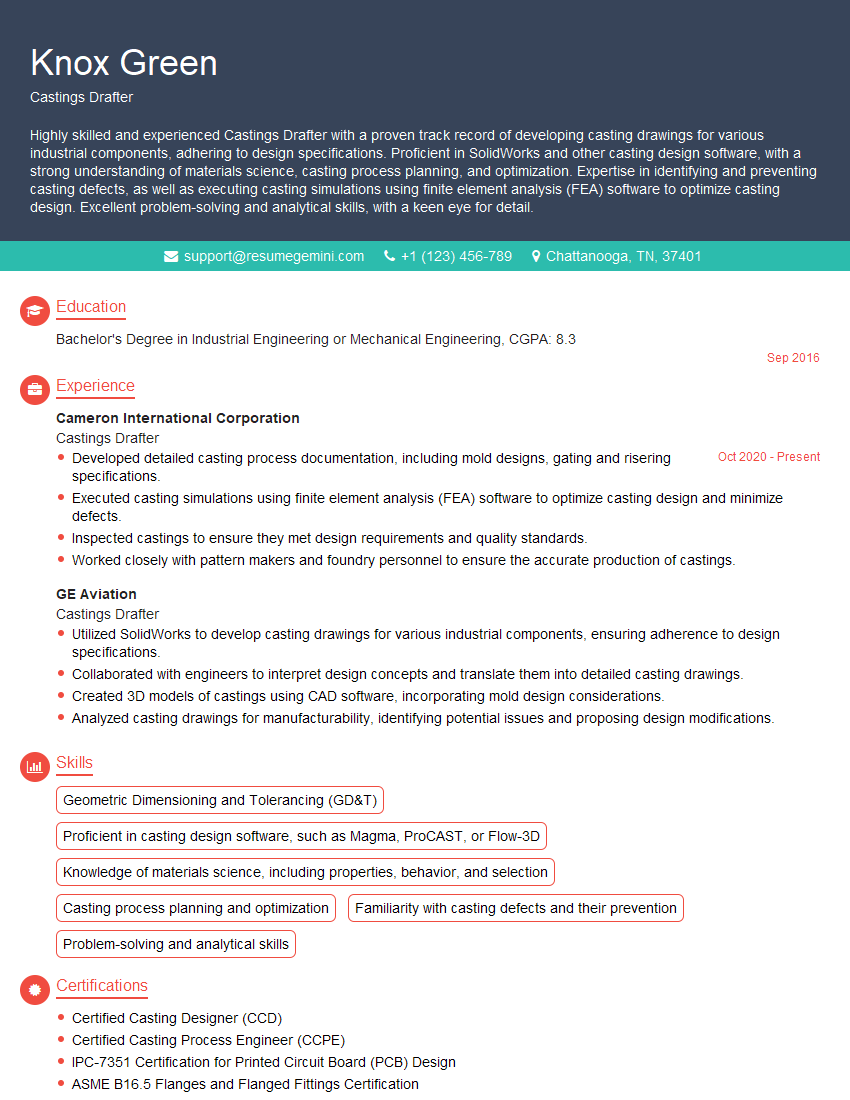

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Castings Drafter

1. What is the difference between a casting drawing and a pattern drawing?

- Casting drawing is a two-dimensional representation of the final cast product, while a pattern drawing is a two-dimensional representation of the pattern used to create the mold.

- Casting drawing includes all the necessary dimensions, tolerances, and other information required to produce the final product, while a pattern drawing only includes the information needed to create the pattern.

- Casting drawing is typically used by the foundry to produce the casting, while a pattern is used by the patternmaker to create the pattern.

2. What are the different types of casting processes?

Sand casting

- Sand casting is the most common type of casting process.

- It is used to produce castings of all shapes and sizes.

- Sand casting is a relatively inexpensive process.

Investment casting

- Investment casting is a precision casting process that produces castings with high dimensional accuracy and surface finish.

- It is used to produce castings of small to medium size.

- Investment casting is a relatively expensive process.

Die casting

- Die casting is a high-pressure casting process that produces castings with high dimensional accuracy and surface finish.

- It is used to produce castings of small to medium size.

- Die casting is a relatively expensive process.

Centrifugal casting

- Centrifugal casting is a casting process that uses centrifugal force to produce castings.

- It is used to produce castings of cylindrical or tubular shapes.

- Centrifugal casting is a relatively inexpensive process.

3. What are the different types of casting defects?

- Porosity

- Inclusions

- Shrinkage

- Cold shuts

- Misruns

- Hot tears

4. What are the different ways to prevent casting defects?

- Using the correct casting process

- Using the correct materials

- Properly preparing the mold

- Properly pouring the metal

- Properly cooling the casting

5. What are the different types of casting tolerances?

- Dimensional tolerances

- Surface finish tolerances

- Weight tolerances

6. What are the different types of casting materials?

- Ferrous metals

- Non-ferrous metals

- Alloys

7. What are the different types of casting equipment?

- Furnaces

- Molding machines

- Pouring equipment

- Cooling equipment

- Inspection equipment

8. What are the different types of casting applications?

- Automotive

- Aerospace

- Medical

- Construction

- Consumer products

9. What are the different types of casting software?

- Computer-aided design (CAD) software

- Computer-aided manufacturing (CAM) software

- Computer-aided engineering (CAE) software

- Simulation software

- Inspection software

10. What are the different types of casting industry trends?

- The use of lightweight materials

- The use of additive manufacturing

- The use of automation

- The use of simulation software

- The use of inspection software

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Castings Drafter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Castings Drafter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Castings Drafters are responsible for creating detailed technical drawings of castings, which are used in the manufacturing process. They work closely with engineers and other designers to ensure that the castings meet the required specifications. The key responsibilities of a Castings Drafter include:

1. Creating detailed drawings of castings

Castings Drafters use computer-aided design (CAD) software to create detailed technical drawings of castings. These drawings include all of the necessary information for the manufacturer to produce the casting, including dimensions, tolerances, and surface finishes.

2. Reviewing and approving engineering drawings

Castings Drafters review and approve engineering drawings to ensure that they meet the required specifications. They may also make changes to the drawings to improve the manufacturability of the casting.

3. Calculating and specifying casting dimensions

Castings Drafters calculate and specify the dimensions of castings based on the engineering drawings. They also determine the best casting process for each application.

4. Preparing casting documentation

Castings Drafters prepare casting documentation, such as technical specifications, inspection reports, and process sheets. This documentation is used by the manufacturer to produce the casting.

5. Working with engineers and other designers

Castings Drafters work closely with engineers and other designers to ensure that the castings meet the required specifications. They may also provide input on the design of the casting to improve its manufacturability.

Interview Tips

To ace the interview for a Castings Drafter position, candidates should be prepared to discuss their skills and experience in the following areas:

1. CAD Software

Castings Drafters must be proficient in using CAD software to create detailed technical drawings. Common CAD software programs include AutoCAD, SolidWorks, and CATIA.

2. Casting Processes

Castings Drafters should have a good understanding of casting processes, such as sand casting, investment casting, and die casting. They should also be able to determine the best casting process for each application.

3. Casting Dimensions

Castings Drafters must be able to accurately calculate and specify the dimensions of castings. They should also be able to determine the tolerances and surface finishes required for each application.

4. Communication Skills

Castings Drafters must be able to communicate effectively with engineers, other designers, and manufacturers. They should be able to clearly explain the casting process and provide technical support.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Castings Drafter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Castings Drafter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.