Feeling lost in a sea of interview questions? Landed that dream interview for Track Dresser but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Track Dresser interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

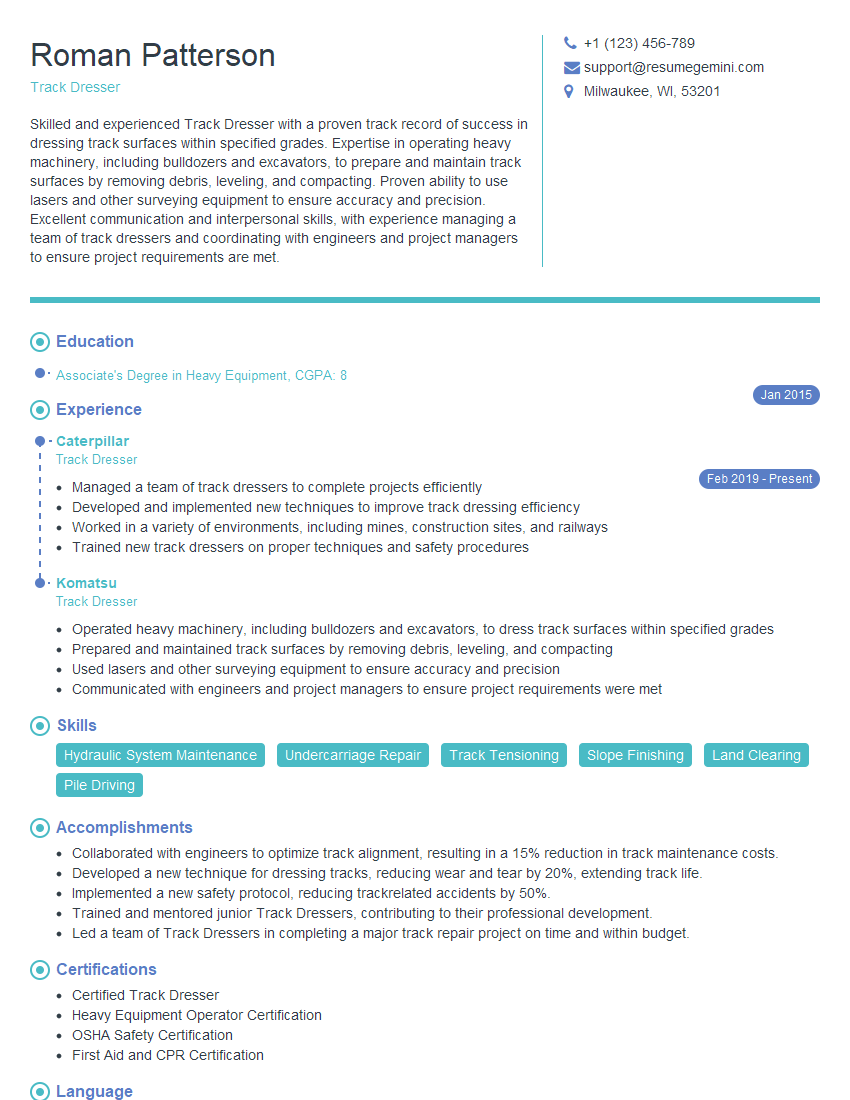

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Track Dresser

1. Explain the process of track dressing?

Track dressing is the process of reshaping and maintaining the track to ensure optimal performance for track-type machines. It involves the following steps:

- Inspection: Examining the track for wear, damage, and tension.

- Cutting: Adjusting the track to the desired length by removing excess links.

- Welding: Joining the track ends together to form a continuous loop.

- Tensioning: Adjusting the track tension to prevent slippage or derailment.

- Lubrication: Applying grease or oil to the track to reduce friction and wear.

2. What are the common types of track dressing equipment?

The most commonly used track dressing equipment includes:

Hydraulic Track Press:

- Used for cutting, welding, and dressing the track.

- Consists of a hydraulic ram, anvil, and track pusher.

Track Tensioner:

- Used to adjust track tension accurately.

- Works by applying force to the track and measuring its elongation.

Track Lubrication System:

- Used to automatically apply grease or oil to the track.

- Reduces friction and wear, prolonging track life.

3. What factors determine the track dressing frequency?

Track dressing frequency depends on several factors, including:

- Operating conditions: Heavy-duty or abrasive environments require more frequent dressing.

- Track type: Different track designs have varying wear rates and require different dressing intervals.

- Machine usage: High-usage machines will require more frequent track dressing.

- Manufacturer recommendations: Specific track dressing intervals are often recommended by the manufacturer.

4. Explain the importance of proper track tension?

Proper track tension is crucial for:

- Traction: Optimal track tension ensures maximum ground contact, resulting in improved traction.

- Reduced slippage: Correct tension prevents excessive track slippage, which can damage the track and undercarriage.

- Longer track life: Properly tensioned tracks experience less wear and tear, extending their lifespan.

- Reduced vibration: Excessive track tension can cause vibration and premature component failure.

5. Describe the potential consequences of incorrect track dressing?

Incorrect track dressing can lead to:

- Track failure: Excessive wear or loose track can cause breakage or derailment.

- Undercarriage damage: Incorrect tension can strain or damage rollers, sprockets, and other undercarriage components.

- Reduced machine performance: Loose or overly tight tracks can impair traction and overall machine efficiency.

- Safety hazards: Failed tracks or improper track dressing can pose safety risks to operators and nearby personnel.

6. How would you troubleshoot a track that is slipping?

Troubleshooting a slipping track may involve:

- Checking track tension: Ensure the track is properly tensioned.

- Inspecting the sprockets and rollers: Look for excessive wear or damage that could cause slipping.

- Verifying lubrication: Ensure the track is adequately lubricated to reduce friction.

- Examining the ground conditions: Loose or uneven terrain can contribute to track slippage.

- Reparing or replacing damaged components: If necessary, replace worn or damaged sprockets, rollers, or track links.

7. What are some best practices for track dressing?

Best practices for track dressing include:

- Regular inspections: Monitor track condition and schedule dressing accordingly.

- Proper equipment: Use appropriate equipment designed for track dressing.

- Precision adjustments: Make precise cuts and welds to ensure proper track fit.

- Correct tensioning: Adjust track tension based on manufacturer specifications.

- Adequate lubrication: Apply the specified grease or oil to minimize wear.

8. Explain the different types of track wear and how to identify them?

Common track wear types include:

Abrasive Wear:

- Characterized by gradual loss of material due to friction with abrasive surfaces.

- Appears as smooth, rounded wear patterns on track components.

Impact Wear:

- Caused by sudden impacts or drops, leading to cracks or deformations.

- Appears as irregular, localized damage on track links or rollers.

Fatigue Wear:

- Results from repeated loading and unloading cycles, causing cracks or breakage.

- Appears as fine cracks on track components that may lead to catastrophic failure.

9. Describe the role of track dressing in preventing track failure?

Regular track dressing is crucial in preventing track failure by:

- Eliminating excessive wear: Proper tensioning and lubrication reduce wear on track components.

- Detecting potential problems: Inspections during track dressing allow for early identification of wear or damage.

- Preventing catastrophic failure: Timely repairs and replacements during track dressing can prevent sudden failures and costly downtime.

10. Explain how track dressing contributes to increased machine efficiency?

Optimized track dressing enhances machine efficiency by:

- Improved traction: Properly tensioned tracks maximize ground contact, increasing traction and reducing energy loss.

- Reduced vibration: Excessive track tension can cause vibration, which leads to premature component wear and reduced operator comfort.

- Lower operating costs: Reduced wear and tear on track components and undercarriage extend machine life and minimize repair expenses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Track Dresser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Track Dresser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Track Dresser is responsible for constructing and maintaining railroad tracks. The job requires precision, attention to detail and physical strength.

1. Track Construction

Track Dressers build new tracks as well as maintain and repair existing ones. They use specialized equipment to lay down ties, rails, and ballast (crushed rock or gravel).

- Lay new tracks according to specifications

- Repair damaged tracks or replace outdated parts

2. Track Maintenance

Track Dressers inspect tracks regularly to identify any problems. They also perform maintenance tasks such as tightening bolts, greasing moving parts.

- Inspect tracks to identify any damage or wear

- Adjust track alignment and level

- Replace worn or damaged ties and rails

3. Ballast Maintenance

Ballast provides drainage and support to the track. Track Dressers maintain the ballast by removing vegetation, adding new ballast, and tamping it down to ensure proper drainage.

- Remove vegetation from ballast

- Add new ballast as needed

- Tamp down ballast to ensure proper drainage

4. Equipment Operation

Track Dressers use various pieces of equipment to perform their job, including track tampers, track liners, and ballast regulators. They must be proficient in operating and maintaining this equipment.

- Operate track tampers to pack ballast under ties

- Use track liners to align rails

- Maintain and repair equipment as needed

Interview Tips

Here are some tips to help you ace your interview for a Track Dresser position:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific Track Dresser position. This will help you understand the company’s culture and the job requirements.

- Visit the company website

- Read industry news and articles

- Talk to people who work in the industry

2. Highlight Your Skills and Experience

In your resume and during the interview, be sure to highlight your skills and experience that are relevant to the Track Dresser position.

- Emphasize your experience in track construction and maintenance

- Highlight your knowledge of railroad equipment

- Demonstrate your physical strength and stamina

3. Be Prepared to Answer Common Interview Questions

There are some common interview questions that you can prepare for in advance. Here are some examples:

- Tell me about your experience in track construction and maintenance.

- What is your knowledge of railroad equipment?

- How do you demonstrate physical strength and stamina in your work?

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the job and that you are taking the interview seriously.

- What are the biggest challenges facing the company right now?

- What is the company culture like?

- What are the opportunities for advancement within the company?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Track Dresser, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Track Dresser positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.