Are you gearing up for a career in Track Laying Equipment Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Track Laying Equipment Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

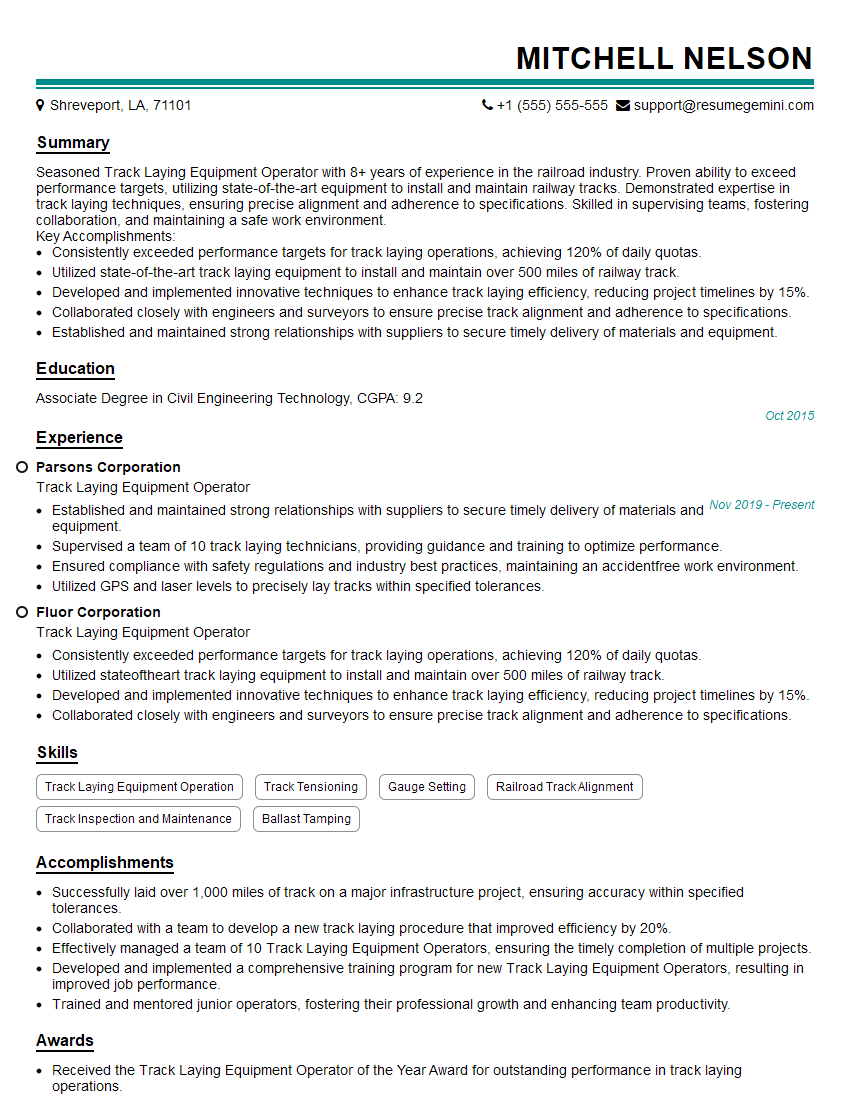

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Track Laying Equipment Operator

1. Describe the various types of track laying equipment that you have operated?

Throughout my career, I have operated a wide range of track laying equipment, including:

- Bulldozers

- Excavators

- Graders

- Loaders

- Skid steers

2. What are the key safety precautions that you observe when operating track laying equipment?

Personal Protective Equipment

- Wear appropriate PPE, including hard hat, safety glasses, gloves, and steel-toed boots.

- Inspect PPE regularly to ensure it is in good condition.

Equipment Inspection

- Conduct pre-operation inspections to identify any potential hazards.

- Check fluid levels, tire pressure, and ensure all controls are functioning properly.

Work Area Assessment

- Identify and avoid overhead hazards, such as power lines.

- Be aware of ground conditions and potential obstacles.

General Safety Practices

- Never operate equipment under the influence of drugs or alcohol.

- Stay alert and maintain a clear line of sight.

- Use hand signals or a spotter when necessary.

3. What are the techniques you use to ensure accurate grading when using a grader?

Achieving accurate grading with a grader requires a combination of skill and precision. Here are some techniques I employ:

- Set up reference points: Establish fixed reference points to guide grading operations.

- Use the blade sensor: Utilize the grader’s blade sensor to maintain the desired slope and elevation.

- Monitor the cross-slope indicator: Continuously monitor the cross-slope indicator to ensure the blade is cutting evenly.

- Check the finished grade: Regularly stop and check the finished grade using a level or straight edge.

- Make adjustments as needed: Adjust the blade angle, tilt, and depth as necessary to achieve the desired grade.

4. Explain how you troubleshoot and resolve hydraulic system issues on track laying equipment?

Troubleshooting and resolving hydraulic system issues require a systematic approach:

- Identify the symptoms: Observe the symptoms of the issue, such as leaks, abnormal noises, or reduced power.

- Check fluid levels and condition: Inspect the hydraulic fluid reservoir for leaks and ensure the fluid is clean and free of contamination.

- Examine hoses and fittings: Look for any loose, damaged, or leaking hoses or fittings.

- Inspect the hydraulic pump: Check the pump for any unusual noises or vibrations, which could indicate a problem.

- Test pressure: Use a pressure gauge to measure the system pressure and compare it to the manufacturer’s specifications.

- Make repairs or replacements: Based on the diagnosis, replace any faulty components or repair leaks.

5. How do you maintain and service track laying equipment to ensure optimal performance?

Regular maintenance and servicing are crucial for optimal performance and longevity of track laying equipment:

- Daily inspections: Conduct daily inspections to identify any potential issues, such as fluid leaks or loose connections.

- Regular servicing: Follow the manufacturer’s recommended maintenance schedule for tasks such as oil changes, filter replacements, and component inspections.

- Track maintenance: Inspect and adjust track tension, clean tracks, and replace worn or damaged components.

- Hydraulic system maintenance: Check hydraulic fluid levels, inspect hoses and fittings, and test system pressure.

- Lubrication: Grease and lubricate all moving parts according to the manufacturer’s specifications.

6. How do you ensure efficient and productive operation of track laying equipment?

Efficient and productive operation of track laying equipment requires a combination of skill and planning:

- Proper equipment selection: Choose the right equipment for the specific task and job site conditions.

- Effective work planning: Plan the work sequence to minimize equipment moves and optimize productivity.

- Efficient operating techniques: Utilize proper techniques for grading, excavating, and other operations to save time and effort.

- Effective communication: Communicate clearly with other crew members and supervisors to ensure smooth coordination.

- Continuous improvement: Seek opportunities to improve efficiency and productivity through training and innovation.

7. How do you handle challenging ground conditions, such as soft or uneven terrain?

Challenging ground conditions require careful assessment and adaptation of operating techniques:

- Assess the conditions: Identify the type and severity of the ground conditions.

- Adjust equipment settings: Modify track tension, blade angle, and other settings to suit the terrain.

- Use proper techniques: Employ techniques such as dozing uphill, using a ripper, or working in stages to tackle uneven surfaces.

- Ensure safety: Prioritize safety by taking precautions to avoid rollovers or getting stuck.

- Seek assistance: If necessary, consult with experienced operators or supervisors for guidance.

8. How do you coordinate with other crew members and supervisors on a construction site?

Effective coordination is vital for a successful construction project:

- Clear communication: Maintain open communication with crew members and supervisors.

- Regular check-ins: Attend project meetings and participate in daily briefings.

- Task delegation: Clearly assign tasks and responsibilities to avoid confusion.

- Site awareness: Be aware of the overall project plan and the activities of other crew members.

- Problem-solving: Collaborate with others to identify and resolve issues proactively.

9. How do you stay updated on the latest advancements and best practices in track laying equipment operation?

Continuous learning is crucial for professional development in this field:

- Attend industry events: Participate in conferences, workshops, and trade shows.

- Read industry publications: Stay informed about new technologies, techniques, and safety regulations.

- Seek training: Pursue additional training to enhance skills and knowledge.

- Network with other operators: Share knowledge and experiences with fellow professionals.

- Utilize online resources: Explore online forums, technical articles, and manufacturer websites for information.

10. What sets you apart from other candidates for this Track Laying Equipment Operator position?

In addition to my technical skills and experience in operating track laying equipment, I possess several qualities that make me an exceptional candidate for this position:

- Strong work ethic: I am committed to delivering high-quality work and meeting deadlines.

- Excellent problem-solving abilities: I can quickly identify and resolve issues that arise on the job site.

- Team player: I work well with others and am always willing to support my crew members.

- Safety-conscious: I prioritize safety in all aspects of my work and strictly adhere to safety regulations.

- Adaptability: I am comfortable working in various conditions and can quickly adapt to changing project requirements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Track Laying Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Track Laying Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Track Laying Equipment Operators are responsible for safely and efficiently operating and maintaining track laying equipment used in a variety of construction and industrial applications.

1. Equipment Operation

Operate and control track laying equipment such as crawler tractors, bulldozers, and excavators.

- Grade, level, and compact soil and other materials.

- Clear land, dig trenches, and move heavy objects.

2. Equipment Maintenance

Perform routine maintenance and repairs on track laying equipment.

- Check fluid levels, lubricate components, and replace filters.

- Inspect equipment for damage or wear and tear.

3. Safety and Compliance

Follow established safety protocols and comply with all applicable regulations.

- Wear appropriate personal protective equipment (PPE).

- Inspect work area for hazards and take necessary precautions.

4. Communication and Collaboration

Effectively communicate with supervisors, colleagues, and clients.

- Provide updates on progress and any issues encountered.

- Collaborate with other team members to ensure project success.

Interview Tips

To prepare for a Track Laying Equipment Operator interview, it is essential to understand the key job responsibilities and develop strategies to effectively showcase your skills and experience.

1. Research the Company and Industry

Learn about the company’s business, industry trends, and the specific project requirements.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Highlight Your Experience and Skills

Emphasize your experience in operating and maintaining track laying equipment, including specific types and attachments.

- Provide examples of projects where you successfully completed complex tasks.

- Quantify your accomplishments whenever possible.

3. Demonstrate Safety and Compliance Awareness

Explain your understanding of safety protocols and regulations related to track laying equipment operation.

- Describe your experience with hazard identification and risk assessment.

- Mention any certifications or training programs you have completed.

4. Emphasize Communication and Teamwork Skills

Showcase your ability to communicate effectively and work collaboratively.

- Give examples of how you have successfully communicated with supervisors, colleagues, and clients.

- Discuss your experience working in a team environment and contributing to project goals.

5. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Seek feedback from a friend, family member, or career counselor.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Track Laying Equipment Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.