Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Track Repair Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Track Repair Worker so you can tailor your answers to impress potential employers.

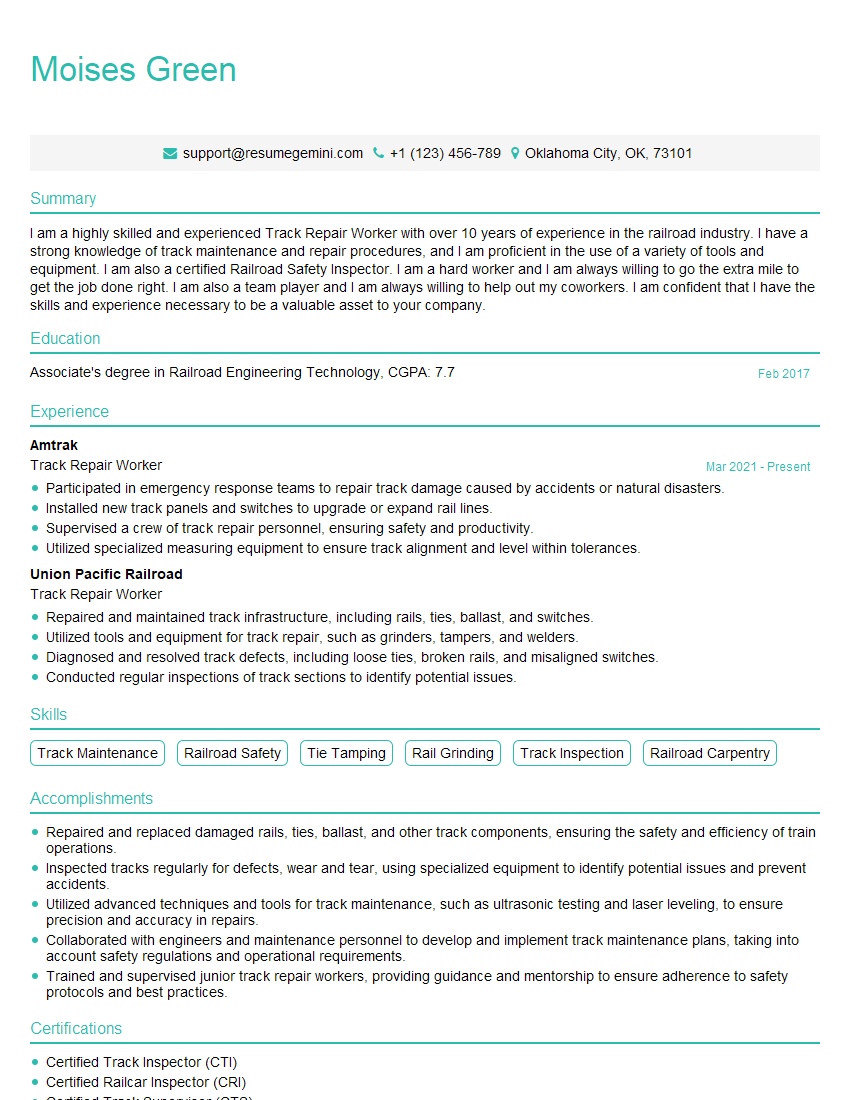

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Track Repair Worker

1. Can you describe the steps involved in replacing a railroad tie?

- Inspect the track to identify the damaged or deteriorated tie.

- Prepare the work area by clearing vegetation and debris.

- Lift the track using a tamper or other equipment.

- Remove the old tie using a tie puller or other tools.

- Clean the tie bed and ballast.

- Insert the new tie into place.

- Tamp or pack the ballast around the new tie.

- Lower the track back into place.

- Align the track and test its stability.

2. How do you ensure the stability and safety of the track after repairs?

Visual inspection

- Checking for proper alignment, spacing, and condition of ties, rails, and fastenings.

- Identifying any defects or damage that could compromise safety.

Mechanical testing

- Using instruments to measure track geometry, such as track gauge, level, and transit.

- Performing ultrasonic or other non-destructive testing to detect internal defects in rails, ties, or other components.

3. What are the different types of track maintenance procedures and their purposes?

- Routine maintenance: Regular inspections, adjustments, and repairs to keep track in good condition, prevent breakdowns, and ensure safety.

- Preventive maintenance: Planned repairs and upgrades to address potential issues before they become major problems, extending the life of the track.

- Corrective maintenance: Repairs to address unexpected damage or failures, restoring the track to a safe and operational state.

- Emergency maintenance: Immediate repairs to address critical issues that threaten the safety or integrity of the track.

4. How do you handle unexpected track defects or emergency situations?

- Assess the situation quickly and determine the severity of the problem.

- Report the issue to the appropriate authorities and request assistance if necessary.

- Implement temporary repairs or safety measures to mitigate the hazard.

- Coordinate with other crews and equipment to implement permanent repairs.

- Document the incident and follow up with reports and inspections to prevent future occurrences.

5. Describe your experience using track repair equipment, such as tampers, liners, and gauges.

- Operating tampers to level and compact ballast under tracks, ensuring stability.

- Using liners to align and position ties for proper track geometry.

- Employing gauges to measure and adjust track parameters, such as rail height, gauge width, and alignment.

6. How do you stay up-to-date on industry best practices and technological advancements in track repair?

- Attending industry conferences and training programs.

- Reading technical journals and publications.

- Consulting with experts and manufacturers.

- Participating in online forums and discussions.

7. What is your understanding of the principles of track geometry and its importance for safe and efficient rail operations?

- Track alignment: Ensuring that rails are parallel and at the correct distance apart for proper wheel contact.

- Track level: Maintaining a consistent elevation to avoid uneven wear and derailments.

- Track gauge: Setting the correct distance between the rails to accommodate trains without causing excessive friction.

- Curvature: Designing tracks with appropriate curves to allow trains to navigate curves safely.

8. Explain the role of ballast in track maintenance and how you ensure its proper installation and maintenance.

- Drainage: Allowing water to drain away from the track, preventing washout and subgrade damage.

- Load distribution: Spreading the load of trains over a wider area, reducing stress on ties and rails.

- Track stability: Holding ties in place and preventing track movement.

- Proper installation: Compacting ballast to the correct density and grading it to facilitate drainage.

- Regular maintenance: Replacing contaminated or degraded ballast, tamping to ensure stability, and removing vegetation growth.

9. Discuss the safety precautions you take when working on or near railroad tracks.

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and high-visibility vests.

- Maintaining a safe distance from moving trains.

- Being aware of the position of other workers and equipment.

- Using proper tools and techniques to avoid accidents.

- Communicating clearly and following established safety protocols.

10. What are your strengths and weaknesses as a Track Repair Worker?

Strengths:- Thorough understanding of track maintenance principles and procedures.

- Proficient in using track repair equipment and tools.

- Excellent physical fitness and ability to work in demanding conditions.

- Strong work ethic and commitment to safety.

- Effective communication and teamwork skills.

- Limited experience in certain specialized repair techniques (can be addressed through training and development).

- Sensitivity to loud noises and confined spaces (can be mitigated through proper PPE and work practices).

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Track Repair Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Track Repair Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Track Repair Worker is responsible for maintaining and repairing railroad tracks and ensuring the safety of trains and passengers. Their key job responsibilities include:

1. Track Inspection and Maintenance

Inspecting railroad tracks regularly to identify defects, wear and tear, or potential hazards.

- Performing routine maintenance tasks such as tightening bolts, replacing worn-out ties, and clearing debris from the tracks.

- Monitoring track conditions, especially during extreme weather conditions, to ensure safety and prevent derailments.

2. Track Repair

Repairing damaged or defective tracks promptly and efficiently to maintain the structural integrity and safety of the railway system.

- Replacing damaged rails, ties, and other track components as needed.

- Levelling and aligning tracks to ensure smooth train operations and prevent derailments.

3. Rail Grinding

Operating rail grinding machines to remove surface defects and restore the rail profile, reducing noise and improving train performance.

- Inspecting and maintaining rail grinding equipment to ensure optimal performance and safety.

- Following established safety protocols and regulations while operating rail grinding machines.

4. Vegetation Management

Controlling vegetation along the tracks to prevent interference with train operations and maintain visibility.

- Trimming trees and bushes to ensure they do not obstruct signals or overhead wires.

- Applying herbicides or other approved methods to control vegetation growth near the tracks.

Interview Tips

To ace an interview for a Track Repair Worker position, it is crucial to prepare thoroughly and showcase your relevant skills and experience. Here are some helpful tips:

1. Research the Company and Position

Research the company’s history, values, and the specific requirements of the Track Repair Worker role. This will demonstrate your interest and commitment to the position.

- Visit the company’s website and social media pages for information about their culture and work environment.

- Read industry publications and online resources to stay up-to-date on the latest track maintenance techniques and best practices.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience related to track inspection, maintenance, and repair. Quantify your accomplishments whenever possible to showcase your impact.

- Describe situations where you identified and resolved track defects, preventing potential derailments or accidents.

- Provide examples of your proficiency in using track maintenance equipment and following safety protocols.

3. Demonstrate Teamwork and Communication Skills

Track Repair Workers often work as part of a team and must be able to communicate effectively with supervisors, colleagues, and other departments. Highlight your ability to collaborate and share information.

- Discuss your experience working on team projects or coordinating with other departments to ensure efficient track maintenance.

- Provide examples of how you have effectively communicated track maintenance issues and concerns to supervisors or other stakeholders.

4. Be Prepared for Physical Demands

Track Repair Workers perform physically demanding work. Be prepared to discuss your fitness level and ability to perform tasks such as lifting heavy equipment, kneeling, and working in various weather conditions.

- Describe your previous experience in physically demanding roles or activities.

- Explain how you maintain your physical fitness and well-being for the demands of the job.

5. Ask Informed Questions

Asking thoughtful questions during the interview demonstrates your interest and engagement. Prepare questions that show your understanding of the role and the company’s operations.

- Inquire about the company’s safety protocols and training opportunities for Track Repair Workers.

- Ask about the team structure and reporting relationships for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Track Repair Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!