Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electric Sewer Cleaning Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

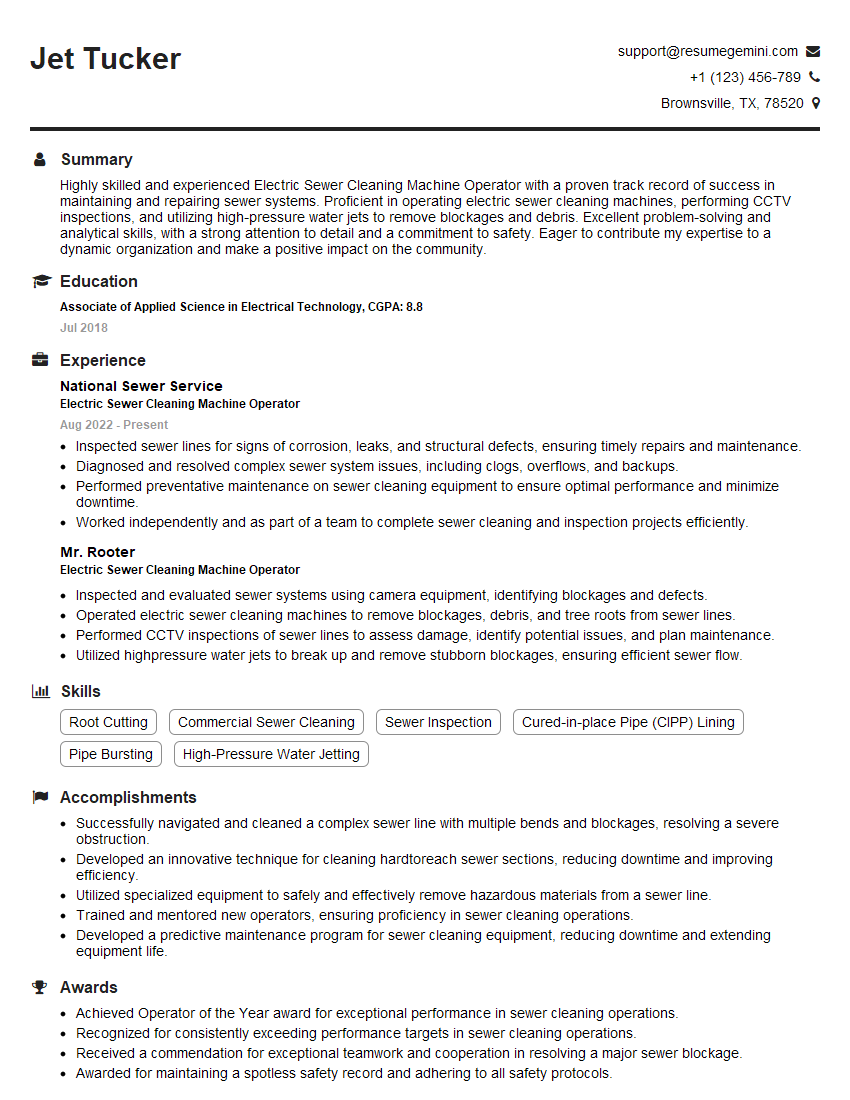

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Sewer Cleaning Machine Operator

1. What are the different types of electric sewer cleaning machines and their uses?

There are several types of electric sewer cleaning machines, each designed for specific applications. Here are the most common types:

- Drum machines: These machines use a rotating drum to power the cleaning cable. They are suitable for smaller-diameter pipes and light-duty cleaning tasks.

- Jetting machines: These machines use high-pressure water jets to clear blockages. They are effective for removing grease, roots, and other stubborn debris.

- Combination machines: These machines combine the features of drum and jetting machines, allowing for both mechanical and hydro-jetting cleaning.

2. How do you determine the right size and type of machine for a specific sewer cleaning job?

To determine the right size and type of machine for a sewer cleaning job, consider the following factors:

- Pipe diameter: The machine’s cable diameter should be slightly smaller than the pipe diameter to ensure proper contact with the pipe walls.

- Blockage type: The type of blockage (e.g., grease, roots, debris) will influence the required cleaning power and cable attachments.

- Length of the run: The machine’s cable length should be long enough to reach the blockage location.

3. What are the safety precautions that must be taken when operating an electric sewer cleaning machine?

For safe operation of electric sewer cleaning machines, observe the following precautions:

- Wear appropriate PPE: This includes gloves, eye protection, and respiratory protection if working in confined spaces.

- Inspect the machine: Check the condition of the machine, cables, and attachments before use.

- Secure the machine: Ensure the machine is stable and will not move during operation.

- Keep hands clear: Keep your hands away from the rotating cable and moving parts.

- Never leave the machine unattended: Stay close to the machine while it is operating.

4. How do you troubleshoot common problems with electric sewer cleaning machines?

Common problems and troubleshooting steps for electric sewer cleaning machines include:

- No power: Check the power cord, circuit breaker, and power outlet.

- Cable stuck: Try reversing the machine to free the cable. If unsuccessful, manually remove the cable.

- Water not flowing: Check the water supply, hose connections, and nozzle for blockages.

- Motor overheating: Let the machine cool down and check for any obstructions or malfunctions.

5. How do you maintain and store electric sewer cleaning machines?

- Regular cleaning: Clean the machine after every use with water and a mild detergent.

- Lubrication: Lubricate moving parts as per the manufacturer’s instructions.

- Cable care: Inspect the cable for damage and replace worn or frayed sections.

- Storage: Store the machine in a dry and protected area, with the cable coiled neatly.

6. What types of sewer blockages can be cleared using an electric sewer cleaning machine?

Electric sewer cleaning machines can effectively clear various types of blockages, including:

- Grease buildup

- Tree roots

- Paper products

- Construction debris

- Mineral deposits

7. How deep can electric sewer cleaning machines reach into a sewer line?

The reach of an electric sewer cleaning machine depends on the length of its cable. Some machines have cables that can extend up to 200 feet, allowing them to reach deep into sewer lines.

8. How do you determine the correct cable speed for different sewer cleaning tasks?

The optimal cable speed for sewer cleaning depends on the type of blockage and the diameter of the pipe. For tough blockages, a slower speed is preferred to provide more torque. For lighter blockages, a higher speed can be used to clear the blockage quickly.

9. What are the advantages of using an electric sewer cleaning machine over a manual sewer snake?

- Higher power: Electric machines provide more power to break through tough blockages.

- Longer reach: Electric machines have longer cables that can reach deeper into sewer lines.

- Faster cleaning: Electric machines rotate the cable faster, enabling quicker cleaning.

10. How often should electric sewer cleaning machines be inspected and serviced?

Regular inspection and servicing of electric sewer cleaning machines are crucial for optimal performance and safety. It is recommended to have the machine inspected by a qualified technician at least once a year.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Sewer Cleaning Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Sewer Cleaning Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Sewer Cleaning Machine Operators are responsible for maintaining and operating electric sewer cleaning machines to clear blockages and debris from sewer lines. Their primary duties involve:

1. Operating Equipment

Operators are proficient in using electric sewer cleaning machines, which consist of a motor, hose, and cutting head. They navigate the machine through sewer lines, utilizing the cutting head to remove blockages.

- Understanding the functionality and operating principles of electric sewer cleaning machines.

- Inspecting and maintaining equipment to ensure optimal performance and safety.

2. Clearing Obstructions

Operators identify and remove various obstructions that cause sewer line blockages, such as tree roots, grease, and debris. They use specialized techniques to clear these blockages effectively.

- Assessing the nature and location of obstructions using cameras or other diagnostic tools.

- Selecting appropriate cutting heads and accessories to remove obstructions efficiently.

3. Troubleshooting and Repairs

Operators are responsible for troubleshooting and making minor repairs to electric sewer cleaning machines. They diagnose issues, replace components, and ensure the equipment is in good working order.

- Identifying and resolving common malfunctions, such as clogged jets or damaged hoses.

- Performing routine maintenance and repairs to extend the lifespan of the equipment.

4. Safety and Compliance

Operators prioritize safety and adhere to environmental regulations while performing their duties. They wear appropriate protective gear and follow established safety protocols.

- Understanding and complying with safety regulations and industry best practices.

- Maintaining a clean and organized work area to prevent accidents and minimize environmental impact.

Interview Tips

Attending an interview for an Electric Sewer Cleaning Machine Operator position requires preparation and a strategic approach. Here are some tips to help candidates ace the interview:

1. Research the Job and Company

Thoroughly research the job responsibilities and the company’s background. This demonstrates your interest and helps you tailor your answers to the specific requirements of the position.

- Read the job description carefully and identify the key skills and experience mentioned.

- Visit the company’s website to learn about their mission, values, and industry standing.

2. Practice Common Interview Questions

Prepare for common interview questions by rehearsing your answers. This will boost your confidence and enable you to articulate your skills and experience effectively.

- Anticipate questions about your experience operating electric sewer cleaning machines.

- Prepare answers to behavioral questions that assess your problem-solving abilities and commitment to safety.

3. Highlight Relevant Experience

Emphasize your experience and skills that are directly relevant to the job. Use specific examples to demonstrate your proficiency in operating electric sewer cleaning machines and resolving blockages.

- Quantify your accomplishments whenever possible, such as the number of blockages cleared or the amount of debris removed.

- Share examples of challenges you faced while operating the equipment and how you overcame them.

4. Demonstrate Safety Awareness

Interviewers value candidates who prioritize safety. Showcase your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Emphasize your knowledge of industry safety regulations and your adherence to established procedures.

- Share examples of how you have proactively identified and mitigated potential hazards while operating the equipment.

5. Ask Questions

Asking thoughtful questions during the interview demonstrates your engagement and interest in the position. Prepare a few questions about the company’s operations, growth prospects, or opportunities for professional development.

- Inquire about the company’s approach to training and employee safety.

- Ask about the opportunities for career advancement within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Sewer Cleaning Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.