Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Transport Tank Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Transport Tank Technician so you can tailor your answers to impress potential employers.

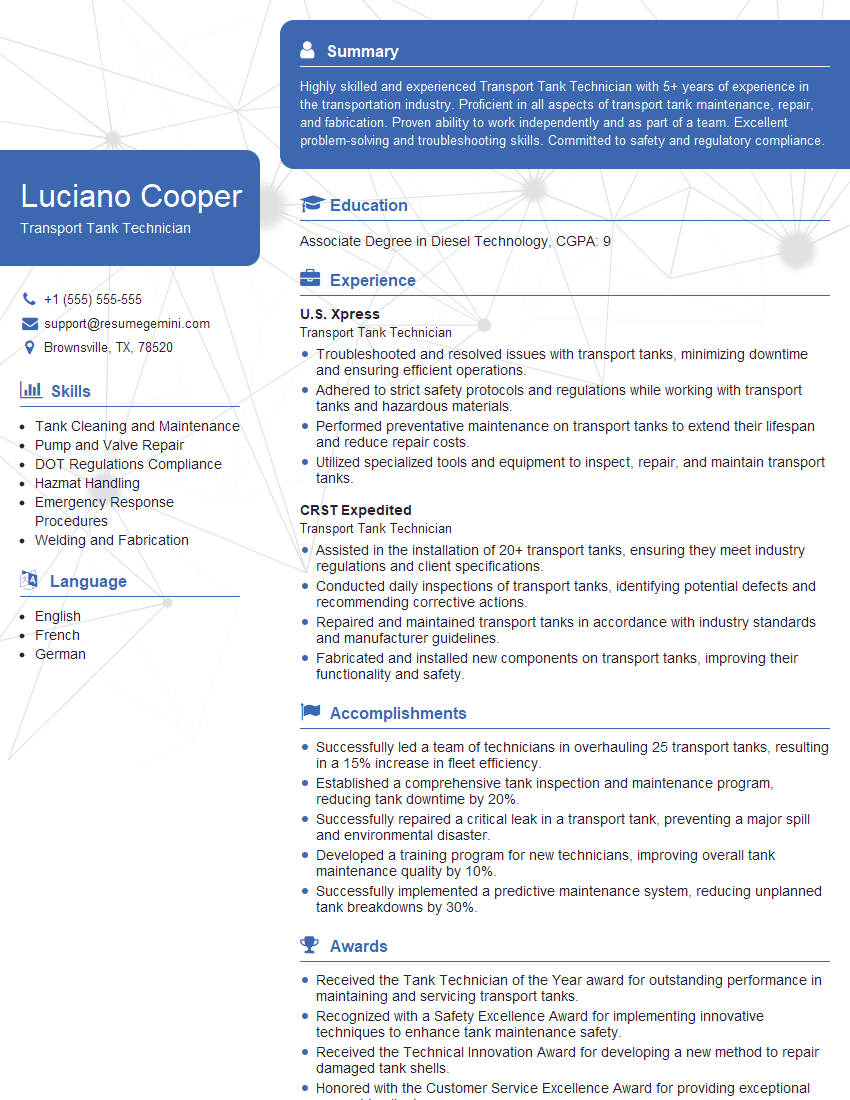

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Transport Tank Technician

1. How do you ensure that the transport tanks are properly maintained and safe for operation?

- Conduct regular inspections to check for any damage or leaks.

- Perform routine maintenance tasks such as cleaning, lubrication, and filter changes.

- Monitor pressure and temperature readings to ensure safe operation.

- Repair or replace any damaged components as necessary.

- Follow all safety protocols and procedures.

2. What steps do you take to prevent and control corrosion in transport tanks?

- Apply protective coatings to the interior and exterior of the tanks.

- Use corrosion-resistant materials in construction.

- Regularly monitor and inspect tanks for signs of corrosion.

- Promptly repair or replace any corroded components.

3. How do you calculate the pressure rating of a transport tank?

- Determine the tank’s geometry and dimensions.

- Calculate the tank’s wall thickness based on the design pressure.

- Select appropriate materials for the tank’s construction.

- Perform stress analysis to verify the tank’s structural integrity.

4. What are the different types of valves used in transport tanks and what are their functions?

- Butterfly valves: used to isolate sections of the tank or control flow.

- Ball valves: used to stop or start flow quickly.

- Check valves: used to prevent backflow.

- Pressure relief valves: used to release excess pressure.

- Safety valves: used to protect the tank from over-pressurization.

5. How do you troubleshoot and repair leaks in transport tanks?

- Identify the location of the leak.

- Determine the cause of the leak (e.g., corrosion, damage, loose fittings).

- Repair the leak using appropriate methods (e.g., welding, patching, replacement).

- Test the tank to ensure the leak has been fixed.

6. What are the safety precautions that must be taken when working with transport tanks?

- Wear appropriate personal protective equipment (PPE).

- Follow all safety protocols and procedures.

- Be aware of the potential hazards of the materials being transported.

- Never enter a confined space without proper training and equipment.

- Handle tanks with care to prevent damage.

7. How do you ensure that the transport tanks are properly loaded and unloaded?

- Follow all loading and unloading procedures.

- Use proper equipment and techniques to load and unload tanks.

- Ensure that the tanks are properly secured during transport.

- Monitor the tanks during loading and unloading to ensure there are no leaks or spills.

8. What are the different types of materials used in the construction of transport tanks and what are their advantages and disadvantages?

- Stainless steel: corrosion-resistant, durable, but expensive.

- Carbon steel: less expensive than stainless steel, but more susceptible to corrosion.

- Aluminum: lightweight, corrosion-resistant, but more expensive than carbon steel.

- Polyethylene: lightweight, corrosion-resistant, but not as strong as metal.

9. How do you stay up-to-date on the latest regulations and industry best practices for transport tank maintenance and operation?

- Attend industry conferences and seminars.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

- Consult with experts in the field.

10. What are the keys to success as a Transport Tank Technician?

- Strong technical skills.

- Attention to detail.

- Commitment to safety.

- Ability to work independently and as part of a team.

- Excellent communication and interpersonal skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Transport Tank Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Transport Tank Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Transport Tank Technicians are responsible for the maintenance and repair of transport tanks, which are used to transport hazardous المواد. Their key responsibilities include:

1. Inspecting and testing tanks

Inspecting and testing tanks to ensure they are in safe working order. This includes checking for leaks, cracks, and other damage.

- Conducting hydrostatic tests to verify tank integrity.

- Using nondestructive testing methods to detect hidden defects.

2. Repairing and replacing components

Repairing or replacing any damaged components, such as valves, pipes, and fittings.

- Welding and fabricating new components as needed.

- Overhauling pumps and other mechanical systems.

3. Maintaining records

Maintaining accurate records of all inspections, repairs, and modifications performed on the tanks.

- Documenting all work orders and safety inspections.

- Keeping up-to-date on industry regulations and standards.

4. Training and supervising

Training and supervising other technicians in the proper maintenance and repair of transport tanks.

- Developing and implementing training programs.

- Mentoring and providing guidance to junior technicians.

Interview Tips

To ace an interview for a Transport Tank Technician position, it is important to be well-prepared and to highlight your skills and experience in the following areas:

1. Technical skills

You should have a strong understanding of the principles of transport tank design and construction. You should also be proficient in the use of welding, fabrication, and other repair techniques.

- Highlight your experience in working with hazardous materials.

- Discuss your knowledge of industry regulations and standards.

2. Safety

Safety is paramount when working with transport tanks. You should have a strong commitment to safety and be familiar with all applicable safety regulations.

- Emphasize your understanding of the potential hazards associated with transport tanks.

- Describe your experience in developing and implementing safety protocols.

3. Communication and teamwork

You should be able to communicate effectively with other technicians, supervisors, and customers. You should also be able to work well in a team environment.

- Share examples of how you have effectively communicated technical information to non-technical audiences.

- Discuss your experience in working on team projects.

4. Problem-solving

You should be able to quickly and effectively troubleshoot problems with transport tanks. You should also be able to develop creative solutions to complex problems.

- Describe a challenging problem you have solved in the past.

- Explain how you approach problem-solving.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Transport Tank Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!