Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Concrete Buildings Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

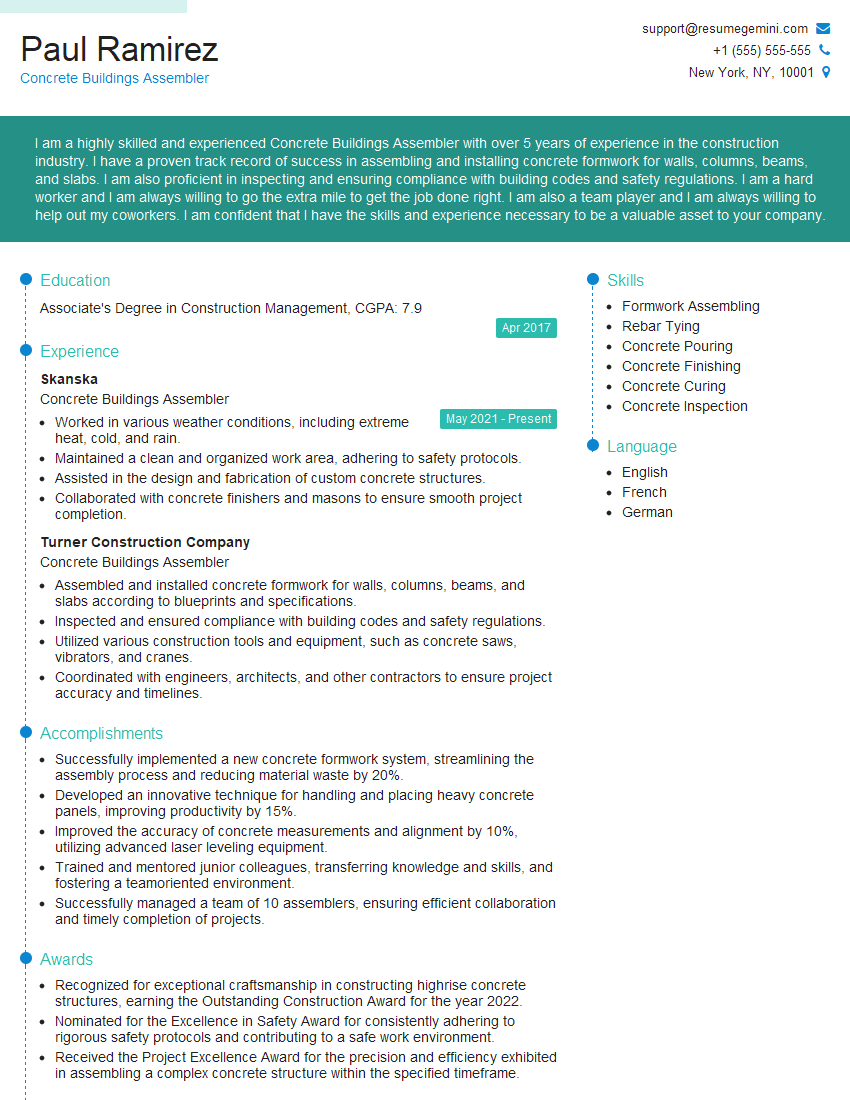

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Buildings Assembler

1. What is the difference between reinforced concrete and pre-stressed concrete?

- Reinforced concrete uses steel reinforcement to enhance tensile strength, while prestressed concrete uses high-tensile steel cables or tendons to apply compression to the concrete before loading.

- Reinforced concrete is more cost-effective for smaller structures, while prestressed concrete excels in large-span structures with heavier loads.

2. Discuss the steps involved in assembling precast concrete elements.

- Preparation: Inspect precast elements, prepare foundations, and ensure site readiness.

- Lifting: Use cranes or hoisting equipment to lift and position elements carefully.

- Alignment: Precisely align elements using surveying tools and leveling devices.

- Connection: Secure elements together using bolts, dowels, or other appropriate connectors.

- Grouting: Fill gaps between elements with grout to enhance structural integrity.

3. How do you ensure the safety of concrete building assemblers?

- PPE: Provide personal protective equipment such as hard hats, safety glasses, and gloves.

- Training: Offer comprehensive training on safety protocols, lifting techniques, and equipment operation.

- Hazard Identification: Conduct thorough site surveys to identify potential hazards and implement mitigation measures.

- Regular Inspections: Perform regular equipment inspections and maintenance to prevent malfunctions.

4. Describe the different types of concrete finishes used in building construction.

- Smooth Finish: Troweled to create a smooth and even surface for aesthetic purposes.

- Exposed Aggregate Finish: Washed or brushed to reveal the aggregate, providing a textured appearance.

- Stamped Finish: Imprinted with patterns or designs to mimic stone or other materials.

- Broom Finish: Brushed with a broom to create a non-slip surface for walkways and patios.

5. What are the advantages of using tilt-up concrete construction?

- Speed: Enables rapid construction by forming and pouring concrete walls on the ground and then lifting them into place.

- Cost-effectiveness: Eliminates the need for extensive formwork, reducing material and labor costs.

- Flexibility: Allows for a wide range of architectural designs and can accommodate openings and penetrations easily.

- Durability: Tilt-up concrete panels are resistant to weather, pests, and fire, providing long-term structural integrity.

6. How do you troubleshoot and repair concrete cracks?

- Identify Cause: Determine the root cause of the crack, such as structural loading, temperature changes, or moisture penetration.

- Repair Method: Select the appropriate repair method based on crack severity, such as patching, epoxy injection, or structural reinforcement.

- Surface Preparation: Clean and prepare the crack surfaces to ensure proper adhesion of repair materials.

- Repair Application: Apply repair materials according to manufacturer’s instructions, ensuring proper curing and bonding.

7. Discuss the importance of concrete curing and how it affects the strength and durability of concrete.

- Strength Development: Curing provides moisture and suitable temperature for cement hydration reactions to occur, resulting in increased concrete strength.

- Reduced Shrinkage: Proper curing minimizes concrete shrinkage, reducing the risk of cracking and improving structural stability.

- Durability Enhancement: Curing enables concrete to develop its full resistance to environmental factors, such as weathering, freezing, and thawing cycles.

8. What are the different types of formwork used in concrete construction?

- Plywood Formwork: Reusable panels made of plywood or oriented strand board (OSB).

- Metal Formwork: Durable and precise forms made of aluminum or steel, often used for large-scale projects.

- Fiberglass Formwork: Lightweight and flexible forms, ideal for complex geometries and curved surfaces.

9. How do you ensure the quality of concrete pours?

- Materials Inspection: Verify the quality and quantity of concrete mix ingredients before pouring.

- Proper Mixing: Ensure thorough mixing to achieve the desired consistency and strength.

- Compaction: Vibrate or tamp the concrete to remove air pockets and ensure proper consolidation.

- Curing: Implement appropriate curing practices to promote hydration and prevent cracking.

10. What are sustainable practices in concrete construction?

- Recycled Materials: Use recycled aggregates and fly ash to reduce environmental impact.

- Permeable Concrete: Construct surfaces that allow water infiltration, reducing runoff and improving stormwater management.

- Energy-Efficient Design: Incorporate concrete elements that contribute to energy efficiency, such as insulated concrete forms.

- Low-Carbon Concrete: Utilize innovative technologies to reduce the carbon footprint of concrete production.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Buildings Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Buildings Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Buildings Assembler is a crucial role in the construction industry, responsible for the assembly and erection of concrete structures. The key job responsibilities include:

1. Assembly and Erection of Concrete Forms

- Assemble and erect formwork for concrete pouring, ensuring proper alignment and stability.

- Follow blueprints and specifications to create complex concrete structures.

2. Concrete Pouring and Finishing

- Assist in the pouring of concrete into formwork, ensuring proper leveling and compaction.

- Finish concrete surfaces using trowels and other tools.

3. Reinforcement Installation

- Install reinforcing bars, mesh, and other structural elements within concrete forms.

- Ensure proper spacing and alignment of reinforcement according to design specifications.

4. Safety and Compliance

- Adhere to all safety regulations and wear appropriate protective gear.

- Maintain a clean and organized worksite.

Interview Preparation Tips

To ace the interview for a Concrete Buildings Assembler position, follow these tips:

1. Research the Company and Position

- Visit the company website to understand their values, mission, and projects.

- Thoroughly review the job description to grasp the specific requirements and expectations.

2. Practice Common Interview Questions

- Prepare answers to frequently asked questions about your experience, skills, and motivations.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide concrete examples.

3. Emphasize Relevant Skills and Experience

- Highlight your experience in concrete formwork, reinforcement installation, and concrete finishing.

- Mention any certifications or training programs you have completed that demonstrate your expertise.

4. Show Confidence and Enthusiasm

- Exude confidence in your abilities and belief in your potential.

- Convey your enthusiasm for concrete work and your passion for contributing to the industry.

5. Prepare Questions for the Interviewer

- Asking thoughtful questions about the company and the role shows your interest and engagement.

- Consider asking about company culture, project pipelines, or growth opportunities.

6. Dress Professionally and Arrive on Time

- Make a positive first impression by dressing appropriately for the interview.

- Arrive on time to demonstrate punctuality and respect for the interviewer’s time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Concrete Buildings Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.