Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Instrument/Control Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

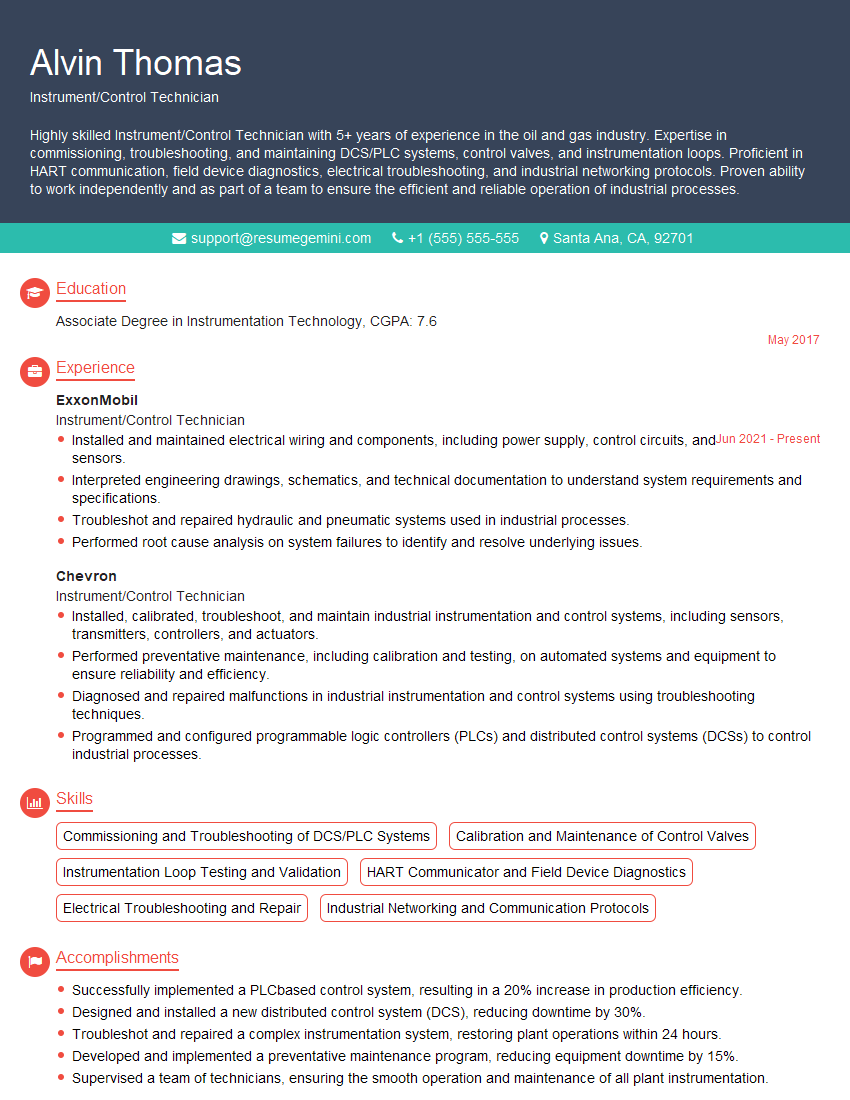

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrument/Control Technician

1. Explain the different types of control loops and their applications in industries?

- Open-loop control: This type of control loop does not use feedback to adjust the control output. Instead, the output is determined solely by the input signal.

- Closed-loop control: This type of control loop uses feedback to adjust the control output. The feedback signal is compared to the setpoint, and the error signal is used to adjust the control output.

- Proportional-integral-derivative (PID) control: This is a common type of closed-loop control loop that uses a combination of proportional, integral, and derivative action to adjust the control output.

2. Describe the working principle of a proportional-integral-derivative (PID) controller?

Working Principle:

- Proportional action: The proportional action produces an output signal that is proportional to the error signal.

- Integral action: The integral action produces an output signal that is proportional to the integral of the error signal. This action helps to eliminate steady-state errors.

- Derivative action: The derivative action produces an output signal that is proportional to the derivative of the error signal. This action helps to improve the response time of the control loop.

Applications:

- Temperature control

- Level control

- Flow control

3. What are the advantages and disadvantages of using a distributed control system (DCS)?

Advantages:

- Improved reliability: A DCS is a redundant system, which means that it can continue to operate even if one of its components fails.

- Scalability: A DCS can be easily scaled up or down to meet the changing needs of a plant.

- Flexibility: A DCS can be easily reconfigured to accommodate changes in the plant’s process.

Disadvantages:

- Higher cost: A DCS is more expensive than a traditional control system.

- Complexity: A DCS is a complex system, which can make it difficult to troubleshoot and maintain.

4. Explain the difference between a programmable logic controller (PLC) and a DCS?

- PLC: A PLC is a small, self-contained controller that is used to automate simple to medium-complexity processes.

- DCS: A DCS is a large, complex system that is used to automate large-scale processes.

5. What are the different types of sensors used in industrial automation and what are their applications?

- Temperature sensors: These sensors measure the temperature of a process fluid.

- Pressure sensors: These sensors measure the pressure of a process fluid.

- Flow sensors: These sensors measure the flow rate of a process fluid.

- Level sensors: These sensors measure the level of a process fluid.

6. What are the different types of actuators used in industrial automation and what are their applications?

- Electric actuators: These actuators use an electric motor to move a valve or other device.

- Pneumatic actuators: These actuators use compressed air to move a valve or other device.

- Hydraulic actuators: These actuators use hydraulic fluid to move a valve or other device.

7. What are the different types of communication protocols used in industrial automation?

- HART: Highway Addressable Remote Transducer

- Modbus: A serial communication protocol

- Ethernet: A high-speed network protocol

8. What are the different types of software used in industrial automation?

- SCADA: Supervisory Control and Data Acquisition

- MES: Manufacturing Execution System

- ERP: Enterprise Resource Planning

9. What are the challenges and opportunities of working in the field of industrial automation?

Challenges:

- Rapid technological change: The field of industrial automation is constantly evolving, which means that technicians need to be constantly learning and adapting.

- Complex systems: Industrial automation systems are often complex and interconnected, which can make it difficult to troubleshoot and maintain them.

Opportunities:

- High demand for skilled workers: The demand for skilled industrial automation technicians is high, which means that there are plenty of job opportunities available.

- Competitive salaries: Industrial automation technicians can earn competitive salaries.

10. Why are you interested in working as an Instrument/Control Technician?

- I am passionate about industrial automation and I am eager to learn more about this field.

- I am a quick learner and I am confident that I can quickly master the skills required to be a successful Instrument/Control Technician.

- I am a team player and I am always willing to go the extra mile to help my colleagues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrument/Control Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrument/Control Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Instrument/Control Technician is responsible for the installation, maintenance, and repair of instrumentation and control systems, following electrical and instrumentation techniques. The primary focus of this role is to ensure the efficient and reliable operation of instrumentation systems, including sensors, transmitters, controllers, and data acquisition equipment, within industrial or laboratory settings.

1. Installation and Commissioning

Involves the physical installation of new instrumentation systems, including the mounting of sensors, wiring, and cabling. Commissioning involves testing and adjusting the installed systems to ensure they meet operational specifications and industry standards.

2. Troubleshooting and Repair

The ability to quickly detect and diagnose faults in instrumentation and control systems is crucial. The technician must have the skills to repair or replace faulty components, such as sensors, actuators, and controllers.

3. Calibration and Maintenance

Regular calibration and maintenance are essential to ensure the accuracy and reliability of instrumentation systems. The technician performs routine checks, adjustments, and preventive maintenance procedures to keep these systems operating within specified tolerances.

4. Documentation and Reporting

The technician is responsible for maintaining accurate and up-to-date documentation on all aspects of instrumentation systems, including installation drawings, maintenance logs, and calibration reports. They may also be required to provide technical reports to management or other stakeholders.

Interview Tips

Adequately preparing for an Instrument/Control Technician interview will significantly improve your chances of success. Here are some helpful tips:

1. Research the Company and Position

Researching the company’s industry, products, and services will demonstrate your interest and knowledge of their operations. Additionally, reviewing the specific requirements and responsibilities of the position will help you tailor your responses to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read industry-related articles and news to stay updated on the latest trends.

- Network with professionals in your field through LinkedIn or industry events.

2. Practice Your Technical Skills

As an Instrument/Control Technician, you will be expected to possess a strong foundation in technical skills. Practice solving common problems related to instrumentation and control systems, such as troubleshooting faults, calibrating sensors, and interpreting data logs.

- Review your textbooks, notes, and laboratory manuals.

- Work on personal projects or simulations to apply your knowledge practically.

- Participate in online forums or discussion groups to engage with other professionals.

3. Prepare for Behavioral Interview Questions

Behavioral interview questions focus on your past experiences and behaviors in specific situations. By using the STAR method (Situation, Task, Action, Result), you can effectively answer these questions and highlight your relevant skills.

- Identify common behavioral interview questions and prepare examples from your experience.

- Use the STAR method to structure your answers clearly and concisely.

- Practice delivering your answers aloud to improve your confidence and fluency.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview. Arrive on time to show respect for the interviewer’s schedule and punctuality.

- Wear business attire or a clean and pressed uniform.

- Arrive at the interview location 10-15 minutes early.

- Bring copies of your resume and any supporting documents.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Instrument/Control Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.