Are you gearing up for a career in Gas Derrick Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Gas Derrick Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

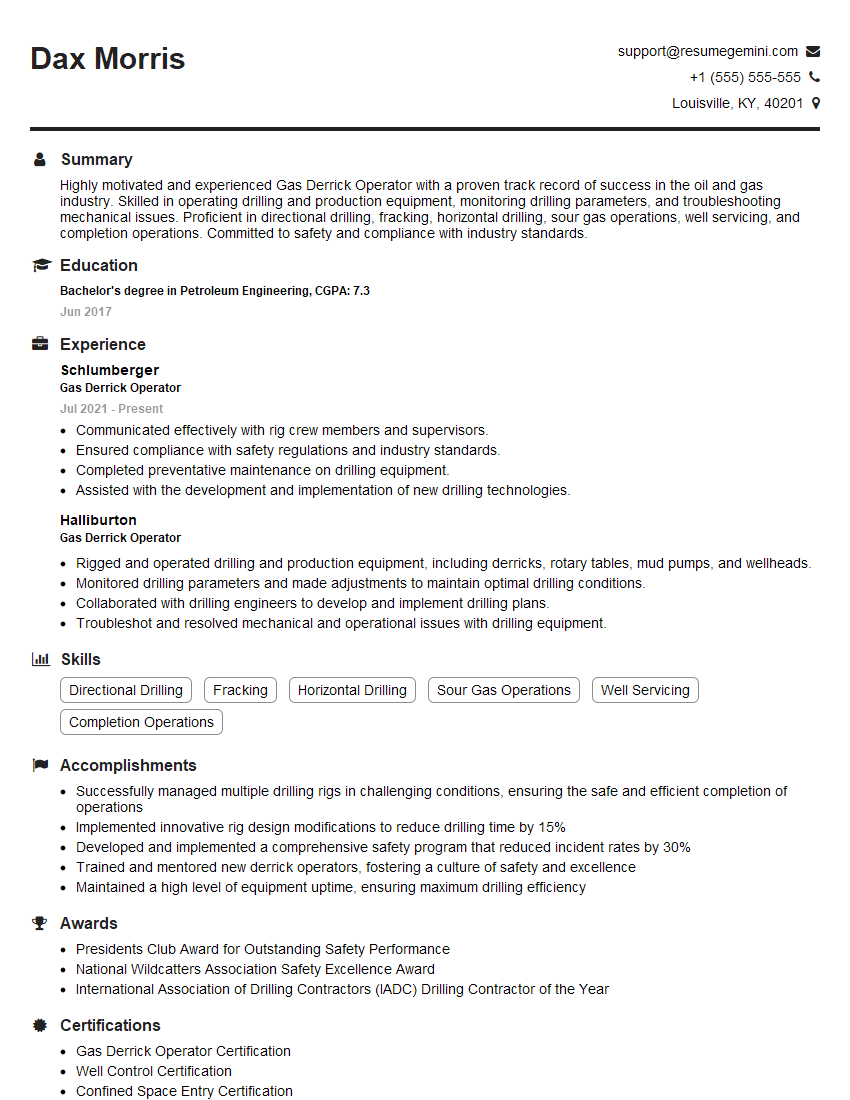

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Derrick Operator

1. Describe the process of installing a gas derrick?

The process of installing a gas derrick involves several key steps:

- Site preparation: The installation site is prepared by clearing the area, leveling the ground, and ensuring proper drainage.

- Foundation construction: A concrete foundation is poured to provide a stable base for the derrick.

- Derrick assembly: The derrick components, including the mast, substructure, and crown block, are assembled on the ground.

- Derrick erection: The assembled derrick is lifted into place using cranes or other heavy equipment.

- Equipment installation: Drilling equipment, such as the rotary table, drawworks, and mud pumps, is installed on the derrick.

- Rigging and testing: The derrick is rigged with wire ropes, sheaves, and other components to ensure its proper functioning.

- Commissioning: The derrick is tested and commissioned to verify its functionality and safety.

2. What are the key safety precautions to consider when operating a gas derrick?

Personal Protective Equipment

- Hard hat

- Safety glasses

- Safety boots

- Gloves

- Hearing protection

Environmental Hazards

- Falling objects

- Rotating equipment

- Electrical hazards

- Suspended loads

- Noise and vibration

Emergency Procedures

- Fire prevention and suppression

- First aid and medical emergencies

- Evacuation procedures

- Spill containment and cleanup

3. Explain the purpose and function of the following components of a gas derrick:

Mast: The primary vertical structure of the derrick, providing height and support for the drilling equipment.

Substructure: The base of the derrick, which anchors it to the foundation and provides stability.

Crown block: A pulley system located at the top of the mast, through which the drilling line passes.

Traveling block: A pulley system that moves up and down the mast, supporting the drilling tools.

Drawworks: A powered winch that controls the movement of the traveling block and drilling tools.

Mud pumps: Equipment that circulates drilling fluid through the drill string to cool and lubricate the drill bit and remove cuttings.

4. Describe the different types of wells that can be drilled using a gas derrick and the purpose of each type.

- Exploration wells: Drilled to locate and evaluate potential hydrocarbon reservoirs.

- Development wells: Drilled to extract hydrocarbons from known reservoirs.

- Injection wells: Used to inject fluids, such as water or gas, into the reservoir to enhance production.

- Monitoring wells: Installed to monitor reservoir conditions, such as fluid levels and pressure.

- Geothermal wells: Drilled to access geothermal energy for heating or electricity generation.

5. Explain the role of drilling fluid in the drilling process.

- Cool and lubricate the drill bit and drill string.

- Remove cuttings from the hole.

- Control formation pressure.

- Form a filter cake on the borehole wall to prevent drilling fluid loss.

- Provide information about the formation through cuttings analysis.

6. Describe the different methods used to complete a well and the purpose of each method.

- Open hole completion: The well is left uncased and the reservoir is accessed directly.

- Cased hole completion: The well is lined with casing to protect it from collapse and to isolate the reservoir.

- Screen completion: A perforated casing or screen is installed to allow fluid flow from the reservoir into the wellbore.

- Gravel pack completion: Gravel is placed around the screen to prevent sand or other formation particles from entering the wellbore.

7. Explain the importance of well logging and the different types of logs that can be obtained.

Well logging is essential for gathering information about the geological formations and reservoir properties. Different types of logs include:

- Mud log: Records drilling parameters and cuttings.

- Electric logs: Measure electrical properties of the formation.

- Radioactive logs: Measure natural radioactivity of the formation.

- Sonic logs: Measure acoustic properties of the formation.

- Image logs: Provide images of the borehole wall.

8. Describe the process of tripping in and tripping out drill string.

Tripping In

- Connect the new drill pipe joint to the top of the existing drill string.

- Lower the drill string into the well until the new joint is in place.

- Tighten the connection.

- Repeat the process until the desired length of drill string is in the well.

Tripping Out

- Break the connection between the top two joints of drill pipe.

- Raise the top joint out of the well using the drawworks.

- Disconnect the raised joint from the drilling equipment.

- Repeat the process until all of the drill string is removed from the well.

9. Explain the purpose of directional drilling and the different techniques used.

Directional drilling allows for drilling wells that are not vertical, but instead follow a specific path. Techniques include:

- Whipstocking: Cutting a window in the casing and drilling a new hole at an angle.

- Jetting: Using a high-pressure jet to wash away formation material and create a new path.

- Rotary steerable systems: Using a steerable drill bit that can be controlled from the surface.

10. Describe the different methods of well stimulation and their applications.

- Acidizing: Injecting acid into the formation to dissolve minerals and improve permeability.

- Fracking: Injecting fluid and proppants into the formation to create cracks and increase flow.

- CO2 injection: Injecting carbon dioxide into the formation to reduce viscosity and improve recovery.

- Steam injection: Injecting steam into the formation to heat the reservoir and reduce oil viscosity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Derrick Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Derrick Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gas Derrick Operators are highly skilled professionals who perform various critical tasks in oil and gas extraction operations. They are responsible for the safe and efficient operation of drilling derricks and associated equipment.

1. Rig Operation

Derrick Operators are responsible for overseeing all aspects of drilling rig operations. This includes:

- Monitoring drilling operations and ensuring compliance with safety procedures

- Operating and maintaining drilling equipment, including derricks, drawworks, and mud pumps

2. Drilling Equipment Maintenance

Derrick Operators play a key role in ensuring that drilling equipment is in good working condition. Their responsibilities include:

- Inspecting and maintaining drilling equipment, including drill bits, drill rods, and casing

- Troubleshooting and resolving equipment issues to minimize downtime

3. Communication and Coordination

Derrick Operators work closely with other members of the drilling crew, including drillers, roughnecks, and geologists. They are responsible for:

- Communicating with the drilling team and providing updates on rig operations

- Coordinating with other departments, such as engineering and maintenance, to ensure smooth drilling operations

4. Safety and Emergency Response

Derrick Operators are responsible for maintaining a safe work environment on the drilling rig. Their duties include:

- Enforcing safety regulations and ensuring that all personnel adhere to safety protocols

- Responding to emergencies and implementing appropriate response measures

Interview Tips

To prepare for a Gas Derrick Operator interview, it is important to understand the key job responsibilities and demonstrate your technical skills and safety consciousness.

1. Research the Industry and Company

Familiarize yourself with the oil and gas industry, drilling techniques, and the company’s operations. This shows the interviewer that you are knowledgeable about the field and have taken an interest in their company.

2. Highlight Your Technical Skills

Emphasize your expertise in drilling equipment operation, maintenance, and troubleshooting. Provide specific examples of your technical abilities and how you have applied them in previous roles.

3. Showcase Your Safety Mindset

Safety is paramount in oil and gas operations. Demonstrate your commitment to safety by describing your experience in adhering to safety protocols, responding to emergencies, and maintaining a safe work environment.

4. Be Prepared for Behavioral Questions

Interviewers often ask behavioral questions to assess your work style and problem-solving abilities. Prepare examples of situations where you demonstrated teamwork, communication, and decision-making skills in a challenging environment.

5. Practice Common Interview Questions

Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?” Prepare concise and engaging responses that highlight your relevant experience and qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gas Derrick Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!