Are you gearing up for an interview for a Spud Driller position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Spud Driller and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

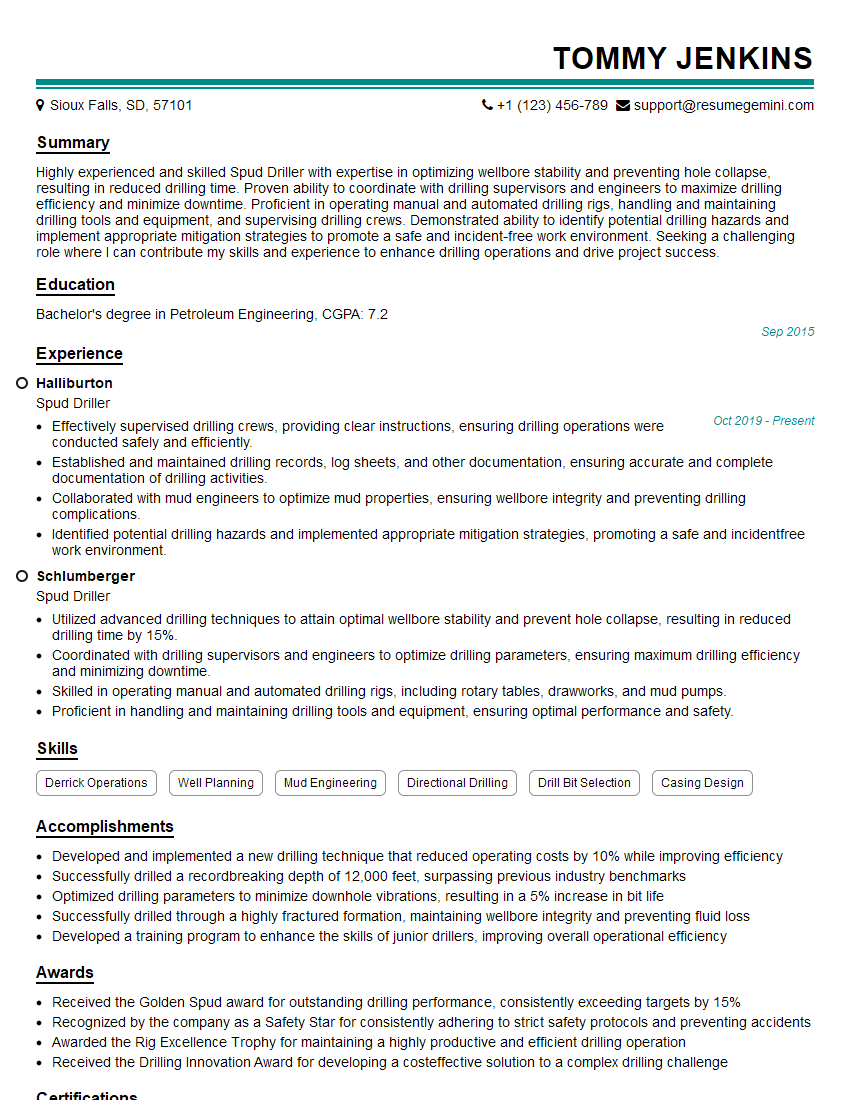

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spud Driller

1. Explain the basic principles of spudding-in a well?

Here is the basic principles of spudding-in a well:

- Establish a stable drilling platform by leveling the rig and ensuring the ground is solid enough to support the weight of the rig.

- Install the blowout preventer (BOP) stack to prevent uncontrolled release of formation fluids.

- Lubricate the drill string and bottom hole assembly (BHA) to reduce friction and prevent galling.

- Drill a pilot hole with a small diameter bit to establish a path for the main borehole.

- Set a casing or conductor pipe into the pilot hole to stabilize the wellbore and prevent collapse.

- Install a diverter to redirect drilling fluids away from the rig in case of a kick or blowout.

- Drill the main borehole to the desired depth, gradually increasing the bit size to enlarge the hole.

- Install production casing or liner to secure the wellbore and isolate different zones.

- Complete the well by installing a production tree or other completion equipment to allow for production.

2. What are the different types of spudding equipment?

Drilling Rig

- Provides power, rotation, and hoisting capabilities for drilling operations.

- Consists of a derrick, drawworks, rotary table, and mud pumps.

Drill String

- Carries drilling fluid to the bit and rotates the bit to break rock formations.

- Consists of drill pipe, collars, and a bottom hole assembly (BHA).

Bit

- Cuts into the rock formation to create the borehole.

- Various types of bits are used depending on formation characteristics.

Casing and Conductor

- Steel pipes installed in the borehole to stabilize the wellbore, prevent collapse, and isolate different zones.

- Conductor pipe is used for the initial phase of drilling, while casing is used for subsequent sections.

Drilling Fluids

- Circulate through the drill string and borehole to cool and lubricate the bit, remove cuttings, and control formation pressure.

- Different types of drilling fluids are used depending on formation conditions and drilling requirements.

3. Describe the safety precautions that must be taken when spudding-in a well?

- Ensure proper rig setup and stability.

- Wear appropriate personal protective equipment (PPE).

- Establish clear communication protocols.

- Have emergency response plans in place.

- Monitor drilling parameters closely.

- Control well pressure effectively.

- Train personnel on safety procedures.

- Maintain a clean and organized work area.

- Follow all applicable regulations and industry standards.

4. How do you determine the appropriate bit size for spudding-in a well?

- Consider the formation characteristics, such as hardness, abrasiveness, and expected drilling rate.

- Take into account the diameter of the casing or conductor to be installed.

- Determine the desired hole size for subsequent drilling operations.

- Refer to industry guidelines and consult with drilling engineers for recommendations.

5. What are the challenges that can be encountered when spudding-in a well?

- Unstable ground conditions.

- Hard or abrasive formations.

- Unexpected geological formations.

- High formation pressure.

- Equipment malfunctions.

- Weather conditions.

- Safety hazards.

6. How do you handle a kick or blowout during spudding-in operations?

- Remain calm and assess the situation.

- Activate the blowout preventer (BOP) stack immediately.

- Increase drilling fluid circulation rate to control formation pressure.

- Divert drilling fluids away from the rig using a diverter.

- Notify relevant personnel and follow emergency response plans.

- Maintain communication with the drilling team.

- Take necessary steps to prevent further escalation of the situation.

7. Describe the role of drilling fluid in spudding-in operations?

- Cools and lubricates the bit and drill string.

- Removes cuttings from the borehole.

- Maintains wellbore stability and prevents collapse.

- Controls formation pressure.

- Protects the environment from drilling fluids and cuttings.

8. Explain the process of setting casing or conductor during spudding-in?

- Run the casing or conductor into the borehole using the drill string.

- Circulate drilling fluid to displace the borehole fluid with casing fluid.

- Set the casing or conductor at the desired depth.

- Cement the casing or conductor in place to provide structural support and isolate different zones.

- Allow the cement to cure before melanjutkan drilling operations.

9. What are the key performance indicators (KPIs) for evaluating the efficiency of spudding-in operations?

- Time to spud-in (days).

- Drilling rate (feet per hour).

- Bit life (hours).

- Circulation rate (gallons per minute).

- Mud weight (pounds per gallon).

- Formation pressure (pounds per square inch).

- Number of safety incidents.

10. Describe the latest advancements in spudding-in technology?

- Automated drilling systems.

- Real-time monitoring and control.

- Improved drilling fluids and additives.

- Advanced bit designs.

- Enhanced safety features.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spud Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spud Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Spud Driller is responsible for overseeing the initial drilling phase of an oil or gas well. They work closely with the drilling team to ensure that the well is drilled safely and efficiently.

1. Manage Drilling Operations

The Spud Driller is responsible for planning and executing all drilling operations. This includes selecting the drilling rig, drilling fluids, and drilling bits. They must also ensure that the drilling crew is properly trained and equipped.

- Plan and execute all drilling operations, including selecting the drilling rig, drilling fluids, and drilling bits.

- Ensure that the drilling crew is properly trained and equipped.

- Monitor drilling progress and make adjustments as needed.

- Troubleshoot and resolve drilling problems.

2. Maintain Drilling Equipment

The Spud Driller is responsible for maintaining all drilling equipment. This includes the drilling rig, drilling fluids, and drilling bits. They must also ensure that the equipment is operating safely and efficiently.

- Maintain all drilling equipment, including the drilling rig, drilling fluids, and drilling bits.

- Inspect drilling equipment regularly and make repairs as needed.

- Lubricate drilling equipment to prevent wear and tear.

- Keep drilling equipment clean and free of debris.

3. Coordinate with Other Team Members

The Spud Driller works closely with other team members, including the drilling foreman, the mud engineer, and the geologist. They must be able to communicate effectively with all team members to ensure that the well is drilled safely and efficiently.

- Coordinate with other team members, including the drilling foreman, the mud engineer, and the geologist.

- Communicate effectively with all team members to ensure that the well is drilled safely and efficiently.

- Resolve conflicts between team members.

- Build and maintain a positive working relationship with all team members.

4. Follow Safety Procedures

The Spud Driller is responsible for following all safety procedures. This includes wearing the proper personal protective equipment, following all drilling safety protocols, and ensuring that the work area is safe.

- Follow all safety procedures, including wearing the proper personal protective equipment, following all drilling safety protocols, and ensuring that the work area is safe.

- Identify and assess potential hazards.

- Develop and implement safety plans.

- Train and educate drilling crew on safety procedures.

Interview Preparation Tips

Preparing thoroughly for your Spud Driller interview is key to making a good impression and increasing your chances of getting the job. Here are a few tips to help you prepare:

1. Research the Company and the Position

Take some time to research the company you’re interviewing with and the specific position you’re applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website and social media pages.

- Read articles about the company in the news and industry publications.

- Talk to people you know who work for the company.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

- Use the STAR method to answer interview questions.

- Prepare for behavioral interview questions.

- Practice answering questions about your experience and skills.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as a Spud Driller. Be prepared to talk about your experience in detail, including your responsibilities, accomplishments, and any challenges you’ve faced. You should also be able to discuss your skills and how they would benefit the company.

- Highlight your experience in drilling operations, equipment maintenance, and team coordination.

- Quantify your accomplishments whenever possible.

- Be prepared to talk about your safety record.

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows the interviewer that you’re respectful of their time and that you’re serious about the job.

5. Be Yourself and Be Confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spud Driller interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.