Are you gearing up for a career in Coiled Tubing Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Coiled Tubing Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

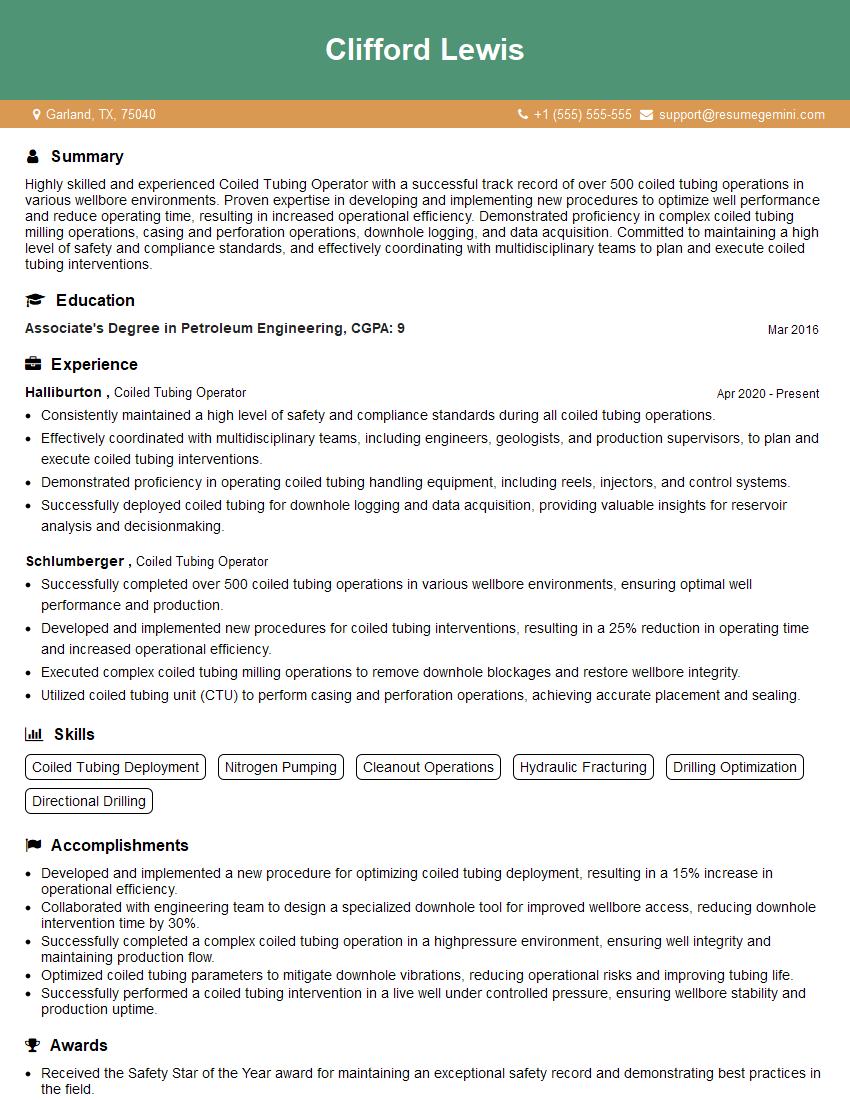

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coiled Tubing Operator

1. Describe the process of tripping in coiled tubing?

- Ensure that the well is secure and that the BOPs are closed.

- Connect the coiled tubing to the wellhead and pressure test the system.

- Open the BOPs and begin pumping fluid down the coiled tubing.

- Lower the coiled tubing into the well to the desired depth.

- Close the BOPs and secure the coiled tubing.

2. What are the different types of coiled tubing interventions?

- Drilling

- Milling

- Fishing

- Logging

- Stimulation

3. What are the key considerations when designing a coiled tubing intervention?

- The wellbore conditions

- The coiled tubing equipment available

- The desired outcome of the intervention

4. What are the risks associated with coiled tubing interventions?

- Equipment failure

- Wellbore damage

- Personnel injury

5. How do you mitigate the risks associated with coiled tubing interventions?

- Proper planning and preparation

- Use of high-quality equipment

- Experienced and trained personnel

6. What are the advantages of using coiled tubing over other methods of well intervention?

- Reduced rig time

- Lower cost

- Increased safety

- Improved flexibility

7. What are the disadvantages of using coiled tubing?

- Limited depth reach

- Potential for equipment damage

- Requirement for specialized equipment and personnel

8. What are the key performance indicators for a coiled tubing operation?

- Rig time

- Intervention success rate

- Safety record

- Cost

9. How do you improve the efficiency of a coiled tubing operation?

- Proper planning and preparation

- Use of high-quality equipment

- Experienced and trained personnel

- Continuous improvement

10. What are the latest trends in coiled tubing technology?

- Development of new materials and equipment

- Improved drilling and milling techniques

- Increased use of real-time data analysis

11. Describe a challenging coiled tubing intervention that you have been involved in and how you overcame the challenges.

- I was involved in a coiled tubing intervention to mill out a fish in a live well. The fish was located at a depth of 10,000 feet and was blocking the production tubing.

- We used a coiled tubing unit with a milling head to mill out the fish. The milling operation was difficult due to the high pressure and temperature of the wellbore.

- We overcame the challenges by using a high-pressure milling head and by circulating a cooling fluid down the coiled tubing.

- We were able to successfully mill out the fish and restore production to the well.

12. What are your career goals?

- I am interested in a career in coiled tubing operations. I would like to learn more about the different aspects of coiled tubing interventions and become a coiled tubing supervisor.

- I am also interested in developing new coiled tubing technologies and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coiled Tubing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coiled Tubing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Coiled Tubing Operator, you will have a range of key responsibilities, including:

1. Coiled Tubing Operations

Playing a crucial role in coiled tubing operations: from unit installation and maintenance to rigging up and down, and coil running.

2. Surface Equipment Operation

Handling surface equipment with expertise, such as the injector head, gooseneck, and reel drive system, to ensure smooth operation.

3. Well Intervention

Actively participating in well intervention operations, including well cleanouts, nitrogen and acid stimulation, and slickline operations.

4. Safety and Compliance

Maintaining a strong focus on safety and compliance at all times, adhering to established protocols and industry standards.

Interview Tips

To prepare for your interview as a Coiled Tubing Operator, here are some insightful tips to help you ace it:

1. Research the Company and Position

Thoroughly research the company you’re applying to, including their values, mission, and specific requirements for the Coiled Tubing Operator position.

2. Highlight Relevant Skills and Experience

Showcase your proficiency in coiled tubing operations, surface equipment handling, and well intervention techniques. Quantify your achievements with specific examples and metrics whenever possible.

3. Emphasize Safety and Compliance Mindset

Emphasize your unwavering commitment to safety and compliance. Highlight your understanding of industry regulations and your ability to maintain a safe work environment.

4. Prepare for Common Interview Questions

Anticipate common interview questions related to coiled tubing operations, such as “Describe your experience in running coiled tubing” or “How do you handle unexpected situations during well intervention?” Prepare thoughtful and concise answers that demonstrate your expertise.

5. Ask Insightful Questions

Prepare thoughtful questions to ask the interviewer during the interview. This shows your interest in the position, the company, and your willingness to actively engage.

6. Professionalism and Enthusiasm

Throughout the interview, maintain a professional demeanor and exude enthusiasm for the role. Your positive attitude and eagerness to contribute will leave a lasting impression.

Next Step:

Now that you’re armed with the knowledge of Coiled Tubing Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Coiled Tubing Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini