Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Woolen Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

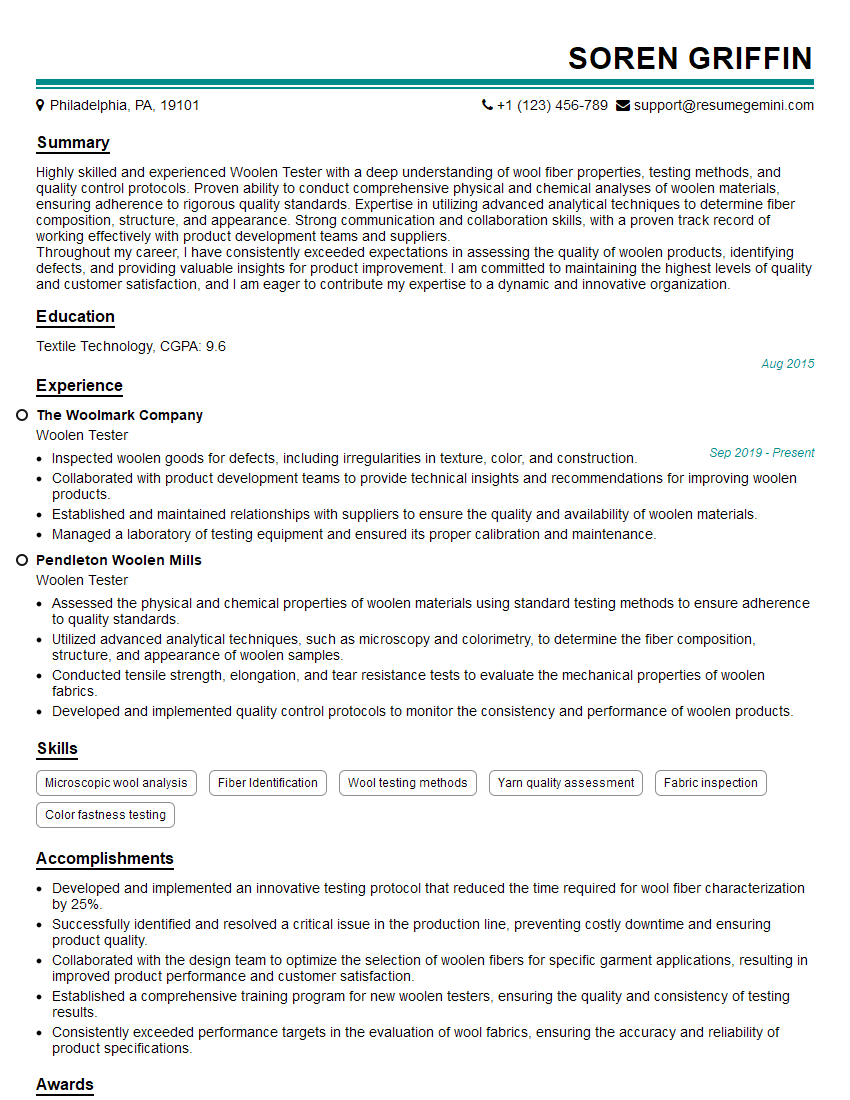

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Woolen Tester

1. What are the key steps involved in evaluating the quality of wool?

As a Woolen Tester, I follow a comprehensive process to evaluate wool quality, including the following key steps:

- Visual Inspection: I start by visually examining the wool to assess its color, luster, crimp, and overall appearance.

- Microscopic Analysis: I use a microscope to examine the individual wool fibers, evaluating their fineness, length, and diameter.

- Tensile Strength Testing: I conduct tensile strength tests to determine the wool’s resistance to breaking under stress.

- Elongation Testing: I measure the wool’s elongation at break, indicating its elasticity.

- Crimp Evaluation: I assess the wool’s crimp pattern, which affects its elasticity, insulation, and appearance.

- Moisture Regain Testing: I determine the wool’s ability to absorb and release moisture, which influences its comfort and durability.

- Shrinkage Evaluation: I evaluate the wool’s susceptibility to shrinkage during washing and drying.

2. Describe the different types of wool fibers and their properties.

Fine Wool

- Extremely soft and smooth

- Fine diameter with high crimp

- Excellent insulation and warmth retention

Medium Wool

- Slightly coarser than fine wool

- Moderately crimped with good elasticity

- Versatile for various applications

Coarse Wool

- Rugged and less pliable

- Lower crimp with higher tensile strength

- Suitable for carpets and industrial use

Specialty Wool

- Unique properties such as curly, lustrous, or colored

- Used in luxury and decorative applications

3. What are the common wool defects and how do you identify them?

Common wool defects include:

- Cottage Wool: Short, coarse, and medullated fibers that reduce wool quality and strength.

- Kemp: Coarse, white, and brittle fibers that lower the wool’s value.

- Burrs: Vegetable matter that can contaminate the wool and damage fibers during processing.

- Seed Coats: Hard, black specks that can damage carding machinery and reduce yarn quality.

- Staining: Discoloration caused by urine, soil, or other contaminants.

- Moths: Insect larvae that can create holes and damage wool fibers.

I identify these defects through visual inspection, microscopy, and laboratory testing.

4. Explain the importance of assessing wool’s moisture regain capacity.

Moisture regain capacity measures the wool’s ability to absorb and release moisture from the air.

- Comfort: Wool’s natural moisture-wicking properties keep the wearer dry and comfortable.

- Insulation: Wool’s hollow fibers trap air, providing insulation even when wet.

- Shrinkage: High moisture regain can lead to shrinkage during washing and drying if not properly controlled.

- Dyeing: Moisture content affects the dye uptake and colorfastness of wool.

5. Describe the role of wool’s crimp in its properties.

Wool’s crimp is a natural wave-like pattern in the fibers.

- Elasticity: Crimp allows wool to stretch and recover without losing its shape.

- Resilience: Crimped fibers enhance wool’s resilience and resistance to matting.

- Insulation: Crimp creates pockets of air, providing excellent insulation.

- Felting: The interlocking of crimped fibers contributes to wool’s felting properties.

6. How do you evaluate the handle of wool?

The handle of wool refers to its softness, smoothness, and texture.

- Tactile Assessment: I manually feel the wool to assess its softness and smoothness.

- Fiber Diameter: Finer fibers contribute to a softer handle.

- Crimp: Crimp reduces the scratchiness of wool, making it more comfortable to wear.

- Surface Friction: I measure the friction between wool fibers to evaluate its smoothness and handle.

7. What are the different standards and grading systems used for wool?

Wool is graded according to various standards and systems, including:

- Micron Grading: Based on the average fiber diameter in microns.

- Yield: Percentage of clean wool obtained after processing.

- Visual Grading: Assesses the wool’s appearance, crimp, and consistency.

- International Wool Textile Organization (IWTO): Sets standards for wool testing and classification.

- Australian Wool Testing Authority (AWTA): Grades Australian wool based on a comprehensive set of criteria.

8. Discuss the factors that affect the strength of wool fibers.

- Fiber Diameter: Thinner fibers are generally stronger.

- Crimp: Crimp increases the surface area of fibers, enhancing their strength.

- Medullation: Medullated fibers with hollow cores are weaker.

- Damage: Physical or chemical damage can weaken wool fibers.

- Breed: Different sheep breeds produce wool with varying strength characteristics.

9. Explain the process of determining the wool’s shrinkage resistance.

- Water Immersion Test: I immerse a wool sample in water and measure its change in length and width.

- Felting Resistance Test: I subject a wool sample to mechanical agitation to evaluate its resistance to felting.

- Dimensional Stability Test: I measure the dimensional changes in a wool sample after washing and drying.

10. Describe the laboratory equipment and techniques used for wool testing.

- Microscope: For examining fiber structure and characteristics.

- Tensile Tester: For measuring fiber strength and elongation.

- Moisture Analyzer: For determining moisture regain capacity.

- Spectrophotometer: For color measurement and dye analysis.

- Shrinkage Tester: For evaluating dimensional stability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Woolen Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Woolen Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Woolen Testers are responsible for ensuring the quality of woolen products, from raw materials to finished goods. They conduct a variety of tests to evaluate the physical and chemical properties of wool, and they report their findings to management.

1. Test Raw Materials

Woolen Testers begin by testing the raw materials used to make wool products. They examine the wool for its fiber length, strength, and color. They also test the wool for the presence of impurities, such as dirt and grease.

- Determine the fiber length, strength, and color of wool

- Test for the presence of impurities, such as dirt and grease

2. Test Finished Products

Woolen Testers also test finished wool products to ensure that they meet quality standards. They examine the products for defects, such as holes, tears, and stains. They also test the products for their colorfastness, shrinkage resistance, and durability.

- Examine products for defects, such as holes, tears, and stains

- Test products for their colorfastness, shrinkage resistance, and durability

3. Report Findings

Woolen Testers report their findings to management in the form of written reports. These reports include the results of the tests that were conducted, as well as the Tester’s recommendations for any necessary corrective actions.

- Write reports summarizing test results and make recommendations for corrective actions

- Communicate findings to management and other stakeholders

4. Stay Up-to-Date on Industry Standards

Woolen Testers must stay up-to-date on industry standards for the testing of wool products. They must also be familiar with the latest testing equipment and techniques.

- Stay abreast of industry standards and best practices

- Attend industry conferences and workshops

Interview Tips

To ace an interview for a Woolen Tester position, you should prepare for the following:

1. Research the Company and the Position

Before your interview, take the time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You should also review your resume and be prepared to discuss your experience and qualifications.

- Visit the company’s website to learn about its history, mission, and values.

- Read the job description carefully to identify the key requirements of the position.

- Review your resume and be prepared to discuss your experience and qualifications in detail.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with testing wool products?

- How do you stay up-to-date on industry standards?

3. Be Prepared to Answer Technical Questions

In addition to the general interview questions, you may also be asked some technical questions about wool testing. Be prepared to discuss your knowledge of the different types of wool tests, the equipment that is used, and the interpretation of test results.

- What are the different types of wool tests that you are familiar with?

- What equipment is used to conduct these tests?

- How do you interpret the results of wool tests?

4. Ask Questions

At the end of the interview, be sure to ask the interviewer any questions that you have about the position or the company. This is a good way to show your interest in the job and to learn more about the opportunity.

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Woolen Tester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.