Are you gearing up for an interview for a Shale Processing Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Shale Processing Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

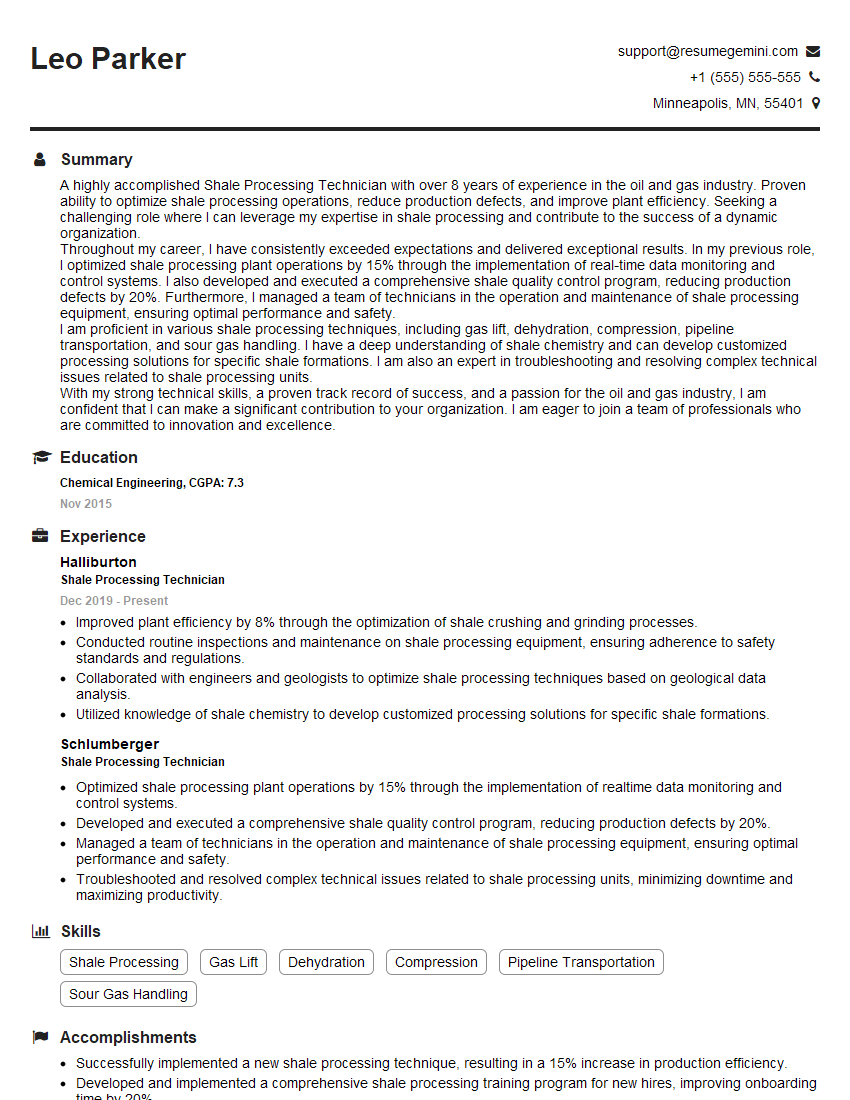

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shale Processing Technician

1. Describe the process of shale gas processing?

The shale gas processing involves several key steps:

- Separation: The raw gas is separated from other components, such as water, sand, and other hydrocarbons.

- Dehydration: The gas is dehydrated to remove water vapor, which can cause corrosion and other problems.

- Compression: The gas is compressed to increase its pressure for transportation.

- Sweetening: The gas is treated to remove hydrogen sulfide (H2S) and other impurities.

- Fractionation: The gas is fractionated to separate different hydrocarbons, such as methane, ethane, propane, and butane.

2. What are the different types of shale gas processing plants?

Centralized Plants:

- Large-scale facilities that process gas from multiple wells.

- Economical for areas with high gas production.

Field-Based Plants:

- Smaller plants located near individual wells.

- Cost-effective for low-volume gas production.

Mobile Plants:

- Transportable units that can be moved between well sites.

- Suitable for remote areas or areas with fluctuating gas production.

3. What are the key safety considerations in shale gas processing?

Shale gas processing involves handling hazardous materials and operating high-pressure equipment. Key safety considerations include:

- Proper training and certification of operators.

- Regular maintenance and inspection of equipment.

- Implementation of safety protocols and emergency response plans.

- Compliance with industry standards and regulations.

- Continuous monitoring and control of process parameters.

4. Describe the role of automation in shale gas processing?

Automation plays a crucial role in shale gas processing:

- Process Control: Automated systems monitor and control process parameters, ensuring optimal efficiency and safety.

- Equipment Monitoring: Sensors and data analytics help detect equipment malfunctions and prevent breakdowns.

- Data Analysis: Automated systems collect and analyze data to identify process improvements and optimize production.

- Remote Monitoring: Shale gas plants can be remotely monitored and controlled from central locations, improving operational efficiency.

5. What are the challenges associated with shale gas processing?

Shale gas processing faces several challenges:

- Water Management: Shale gas production generates large volumes of wastewater that need to be treated and disposed of.

- Impurity Removal: Shale gas contains impurities such as H2S and CO2, which require specialized treatment processes.

- Environmental Impact: Shale gas processing can have environmental impacts, such as air pollution and water contamination.

- Fluctuating Gas Prices: The profitability of shale gas processing can be affected by fluctuating gas prices.

6. Explain the importance of sample analysis in shale gas processing?

Sample analysis is crucial in shale gas processing for:

- Quality Control: Monitoring the composition and properties of the gas throughout the processing chain.

- Process Optimization: Identifying areas for improvement and making adjustments to ensure efficient operation.

- Trouble Detection: Detecting and diagnosing equipment malfunctions or process disturbances.

- Safety Control: Ensuring the gas meets safety specifications and does not pose any risks to operators or the environment.

7. What are the common maintenance practices in shale gas processing plants?

Common maintenance practices include:

- Equipment Inspection: Regularly inspecting equipment for signs of wear, corrosion, or damage.

- Preventive Maintenance: Performing scheduled maintenance tasks to prevent breakdowns and extend equipment life.

- Calibration and Testing: Calibrating and testing instruments and sensors to ensure accuracy.

- Lubrication: Lubricating moving parts to minimize friction and wear.

8. Describe the role of corrosion management in shale gas processing?

Corrosion management is crucial due to the presence of corrosive elements in shale gas:

- Corrosion Monitoring: Using corrosion sensors and inspections to identify areas susceptible to corrosion.

- Corrosion Protection: Implementing protective coatings, corrosion-resistant materials, and cathodic protection systems.

- Corrosion Mitigation: Conducting corrosion analyses and implementing strategies to reduce corrosion rates.

9. What are the latest advancements in shale gas processing technology?

Advancements include:

- Membrane Technology: Using membranes to separate gases efficiently, reducing energy consumption.

- Chemical Looping Combustion: Using oxygen carriers to burn impurities, capturing CO2, and improving efficiency.

- Artificial Intelligence (AI): Employing AI algorithms for process optimization, predictive maintenance, and safety management.

10. How do you stay up-to-date with developments in shale gas processing?

I stay updated by:

- Attending industry conferences and seminars.

- Reading technical journals and publications.

- Participating in online forums and discussion groups.

- Networking with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shale Processing Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shale Processing Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Shale Processing Technician plays a critical role in the shale processing industry, responsible for operating and maintaining equipment, monitoring processes, and ensuring the efficient and safe production of shale products. Their key job responsibilities include:

1. Equipment Operation and Maintenance

Operate and maintain various shale processing equipment, including crushers, screens, conveyors, and pumps.

- Perform regular equipment inspections and maintenance to prevent breakdowns and ensure optimal performance.

- Troubleshoot and resolve equipment issues promptly and effectively.

2. Process Monitoring and Control

Monitor and control shale processing parameters, such as feed rates, temperatures, and pressures.

- Make necessary adjustments to process settings to optimize production efficiency and product quality.

- Keep accurate records of process data for analysis and optimization purposes.

3. Quality Control and Assurance

Conduct quality control tests on shale products to ensure they meet specifications.

- Identify and resolve any quality issues or deviations from standards.

- Implement quality control procedures and maintain quality records.

4. Safety and Environmental Compliance

Adhere to safety regulations and guidelines to ensure a safe work environment.

- Wear appropriate personal protective equipment (PPE) and follow all safety protocols.

- Monitor environmental emissions and ensure compliance with environmental regulations.

Interview Tips

Preparing for an interview for a Shale Processing Technician position requires thorough research and preparation. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Gain a good understanding of the company’s operations, industry trends, and the specific role you are applying for.

- Visit the company’s website and social media pages to learn about their mission, values, and recent projects.

- Read industry news and articles to stay informed about the latest developments in shale processing.

2. Highlight Relevant Skills and Experience

Carefully review the job description and identify the key skills and experience required for the position.

- In your resume and interview responses, emphasize your proficiency in operating and maintaining shale processing equipment.

- Provide examples of your experience in process monitoring, quality control, and safety compliance.

3. Prepare for Technical Questions

Expect to encounter technical questions during the interview that assess your understanding of shale processing principles and equipment.

- Review common shale processing techniques, such as crushing, screening, and flotation.

- Be familiar with the different types of shale processing equipment and their functions.

4. Practice Answering Behavioral Questions

Many interviewers use behavioral questions to evaluate your problem-solving, teamwork, and communication skills.

- Prepare for questions about how you handled equipment malfunctions, resolved quality issues, or worked effectively in a team.

- Use the STAR method (Situation, Task, Action, Result) to provide clear and structured answers.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude.

- Dress professionally and arrive on time for the interview.

- Be polite and respectful to the interviewer and ask insightful questions that demonstrate your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shale Processing Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!