Are you gearing up for an interview for a Boring Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Boring Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

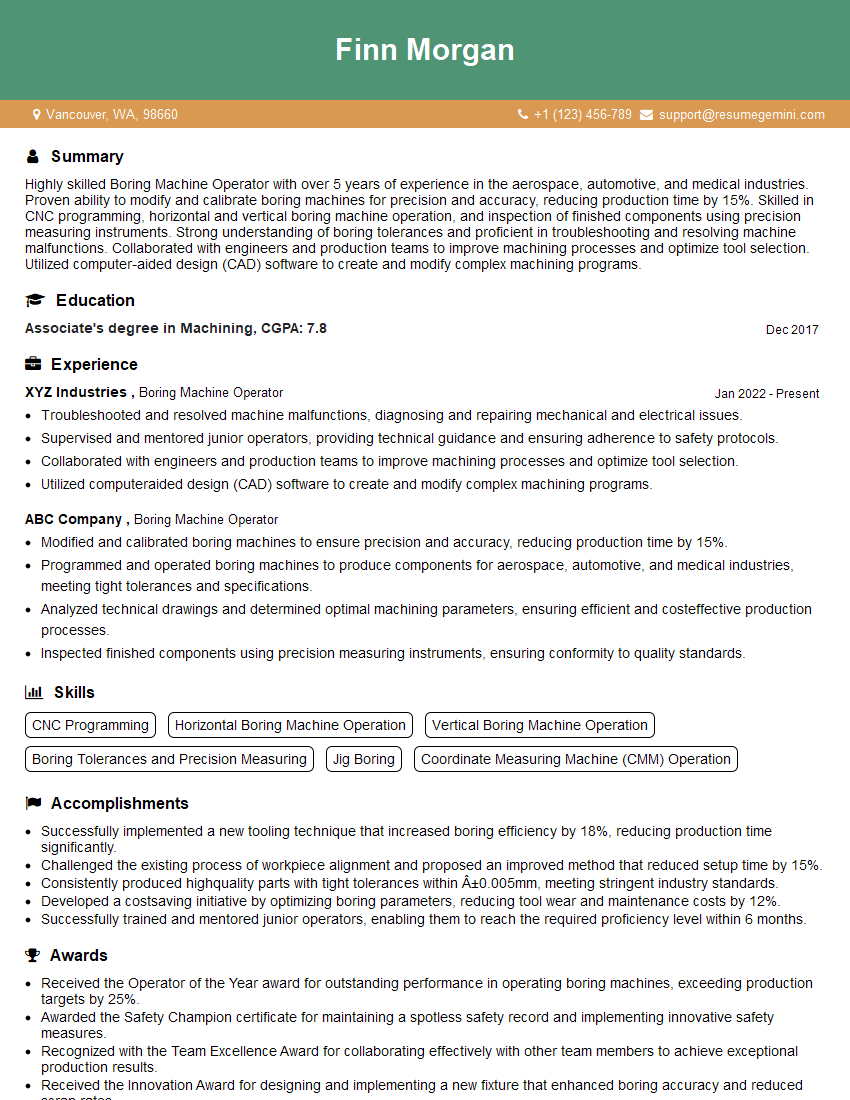

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boring Machine Operator

1. Explain the process of setting up and operating a boring machine?

- First, I secure the workpiece in the machine’s chuck or on the worktable, ensuring proper alignment and stability.

- Next, I select the appropriate cutting tool and mount it in the machine spindle.

- I then adjust the spindle speed, feed rate, and depth of cut according to the material being machined and the desired hole specifications.

- Once the machine is set up, I start the boring process by advancing the cutting tool into the workpiece.

- Throughout the operation, I monitor the process closely, making any necessary adjustments to ensure precisión and efficiency.

2. How do you determine the correct cutting tool and parameters for a specific boring operation?

subheading of the answer

- I consider the material of the workpiece and its hardness.

- I also take into account the desired hole size, depth, and tolerance.

subheading of the answer

- Based on these factors, I select the appropriate cutting tool material, such as carbide or high-speed steel.

- I then determine the optimal spindle speed and feed rate to achieve the desired cutting performance and surface finish.

3. How do you ensure the accuracy and precision of bored holes?

- Before starting the boring operation, I carefully check the alignment of the machine and the workpiece.

- I also use precision measuring tools, such as dial indicators or micrometers, to ensure that the hole is bored to the specified dimensions.

- Throughout the process, I monitor the cutting tool’s condition and make adjustments as needed to maintain accuracy.

4. What are the common problems that can occur during boring operations and how do you troubleshoot them?

- Chattering or vibration can occur due to improper tool selection, excessive feed rates, or workpiece imbalance.

- To troubleshoot, I would check the tool condition, adjust the cutting parameters, and ensure that the workpiece is securely clamped.

- Another common issue is tool breakage, which can be caused by overloading the tool or using a dull cutting edge.

- In this case, I would replace the tool and inspect the machine for any potential issues.

5. How do you maintain and inspect boring machines to ensure optimal performance and safety?

- I regularly clean and lubricate the machine according to the manufacturer’s recommendations.

- I also inspect the spindle, bearings, and other critical components for wear or damage.

- If any issues are identified, I take prompt action to repair or replace the affected parts.

- Additionally, I follow established safety protocols, such as wearing appropriate PPE and observing proper lockout/tagout procedures.

6. What types of materials can be bored using a boring machine?

- Boring machines can be used to bore holes in a wide range of materials including metals, plastics, and composites.

- The specific materials that can be bored depend on the machine’s capabilities and the type of cutting tool used.

- For example, carbide cutting tools are suitable for boring hard materials such as steel, while high-speed steel tools are more suitable for softer materials such as aluminum or brass.

7. What are the safety precautions that should be taken when operating a boring machine?

- Always wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves.

- Ensure that the machine is properly grounded and that all guards and shields are in place.

- Be aware of the location of the cutting tool and keep hands clear of the cutting area.

- Never attempt to operate the machine while under the influence of drugs or alcohol.

- Follow all established safety protocols and procedures.

8. How do you measure the accuracy of a bored hole?

- The accuracy of a bored hole can be measured using various tools, such as a dial indicator, bore gauge, or micrometer.

- These tools allow me to measure the hole’s diameter, depth, and roundness to ensure it meets the specified tolerances.

9. What is the difference between boring and drilling?

- Boring is a machining process that involves enlarging an existing hole or creating a new hole with a high degree of accuracy and precision.

- Drilling, on the other hand, is primarily used to create new holes and is typically less precise than boring.

10. How do you ensure that the bored hole is perpendicular to the surface of the workpiece?

- To ensure that the bored hole is perpendicular to the surface of the workpiece, I use a boring head or a boring bar that is mounted in the spindle of the boring machine.

- The boring head or boring bar is then aligned with the surface of the workpiece using a dial indicator or a precision level.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Boring Machine Operator is responsible for operating and maintaining boring machines used in the manufacturing process. They ensure that the machines are operating correctly and that the parts being produced meet the required specifications. Key job responsibilities include:

1. Machine Operation

• Operate boring machines to create holes in various materials such as metal, plastic, and wood.

• Follow blueprints and specifications to determine the correct hole size, depth, and location.

2. Machine Maintenance

• Perform routine maintenance on boring machines, including cleaning, lubrication, and minor repairs.

• Identify and troubleshoot any mechanical or electrical issues that arise during operation.

3. Quality Assurance

• Inspect parts produced by the boring machine to ensure they meet the required quality standards.

• Use measuring tools and gauges to verify hole dimensions and surface finish.

4. Safety and Compliance

• Adhere to all safety regulations and procedures related to the operation of boring machines.

• Wear appropriate personal protective equipment, such as safety glasses and gloves.

Interview Tips

Preparation is key to acing any job interview. Here are some tips to help you prepare for a Boring Machine Operator interview:

1. Research the Company and Position

• Visit the company’s website and read about their products, services, and culture.

• Review the job description carefully and identify the key skills and qualifications required.

2. Practice Your Answers

• Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

• Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills.

3. Highlight Your Skills and Experience

• Emphasize your experience with operating boring machines, including the specific types of machines you’ve worked with.

• Showcase your knowledge of quality assurance procedures and your ability to troubleshoot mechanical issues.

4. Demonstrate Your Safety Awareness

• Highlight your understanding of safety regulations and your commitment to following safe work practices.

• Provide examples of how you have ensured the safety of yourself and others while operating machinery.

5. Ask Thoughtful Questions

• At the end of the interview, ask thoughtful questions that demonstrate your interest in the position and the company.

• This shows that you’re engaged and that you’re taking the interview seriously.

Next Step:

Now that you’re armed with the knowledge of Boring Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Boring Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini