Feeling lost in a sea of interview questions? Landed that dream interview for Churn Drill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Churn Drill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

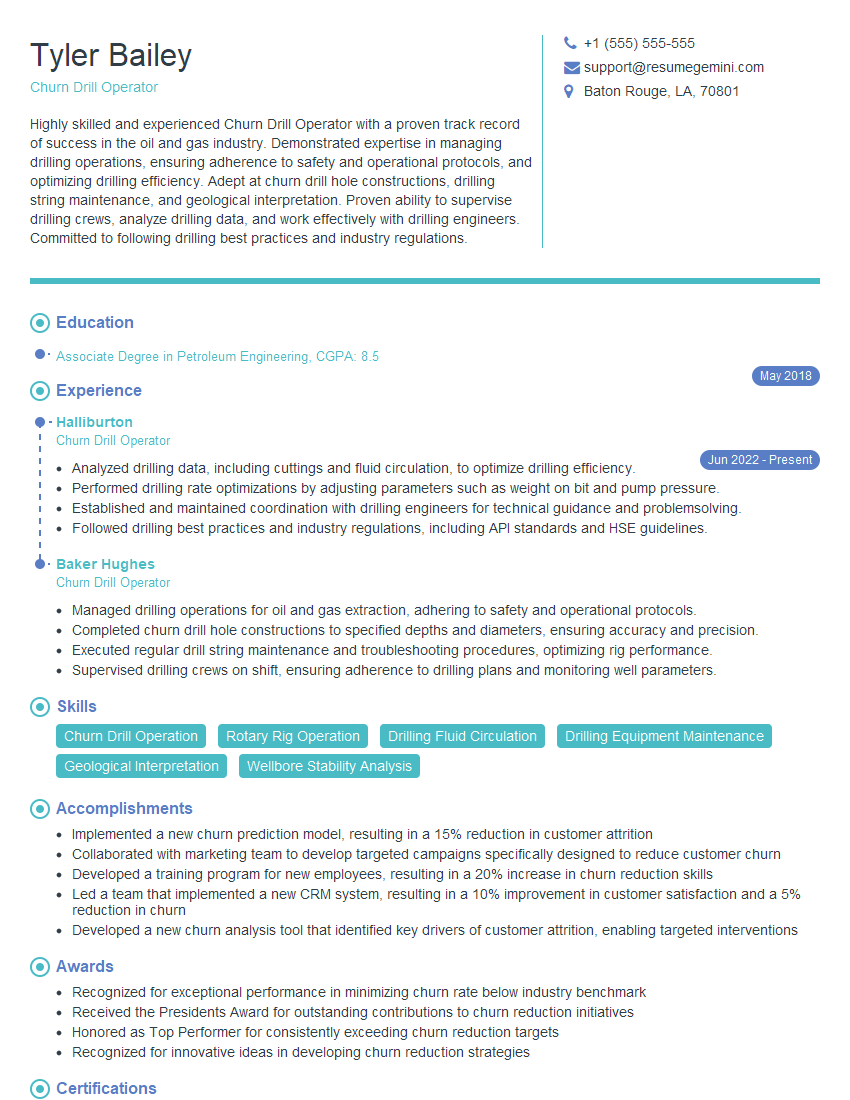

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Churn Drill Operator

1. Explain the principle of operation of a churn drill?

The churn drill, also known as a percussion drill, operates on the principle of repeatedly lifting and dropping a heavy bit to break down the rock formation. The bit is attached to a cable or rope, which is wound around a drum. A motor or engine powers the drum, which rotates to lift and drop the bit. As the bit strikes the rock, it breaks it down into smaller pieces, which are then removed from the hole by a bailer or other means.

2. What are the different types of churn drills available?

Cable Tool Rig

- Uses a cable to raise and lower the drilling tools.

- Suitable for drilling in soft to medium-hard formations.

Rotary Rig

- Rotates the drill pipe to drill the hole.

- Used for drilling in hard formations.

Downhole Hammer Rig

- Uses a downhole hammer to provide percussive force.

- Efficient for drilling in hard and fractured formations.

3. How do you calculate the penetration rate of a churn drill?

The penetration rate is calculated by dividing the depth drilled by the drilling time. The units are typically meters per hour or feet per hour. Factors affecting the penetration rate include the rock formation, bit type, drilling fluid, and equipment efficiency.

- Penetration Rate = Depth Drilled / Drilling Time

4. What are the common problems encountered during churn drilling and how do you resolve them?

- Bit wear: Replace or sharpen the bit.

- Stuck pipe: Use jarring tools or apply torque to free the pipe.

- Excessive deviation: Adjust drilling parameters, use stabilizers, or consider directional drilling techniques.

- Lost circulation: Add lost circulation materials to the drilling fluid or use a casing shoe.

5. How do you maintain and inspect a churn drill rig?

- Regularly inspect the drill bit, drill pipe, and other components for wear, damage, or corrosion.

- Lubricate moving parts and ensure proper alignment.

- Inspect the drilling fluid system, including pumps, tanks, and hoses, for leaks or blockages.

- Check the engine or motor for proper operation and maintenance.

6. What safety precautions should be taken when operating a churn drill rig?

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, gloves, and work boots.

- Follow established drilling procedures and guidelines.

- Maintain a safe working area, free from trip hazards and debris.

- Be aware of potential hazards, such as falling objects, rotating equipment, and electrical connections.

7. How do you handle and transport drilling samples?

- Collect samples at regular intervals and store them in labeled containers.

- Ensure proper labeling and documentation of sample depth, location, and other relevant information.

- Transport samples carefully to avoid contamination or damage.

8. What is the role of drilling fluid in churn drilling?

- Lubricates and cools the drill bit and drilling tools.

- Removes cuttings from the hole.

- Maintains wellbore stability and prevents blowouts.

9. Explain the purpose and components of a bailer.

A bailer is a tool used in churn drilling to remove cuttings and debris from the hole. It consists of a cylindrical body with a valve at the bottom. The bailer is lowered into the hole and filled with cuttings. The valve is then closed, and the bailer is retrieved. The cuttings are then dumped out of the bailer.

10. How do you troubleshoot a churn drill that is not making progress?

- Check the bit for wear or damage.

- Inspect the drilling fluid for proper viscosity and circulation.

- Ensure that the drilling parameters (e.g., weight on bit, rotational speed) are appropriate for the formation.

- Consider using different drilling techniques or tools.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Churn Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Churn Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Churn Drill Operator is responsible for the safe and efficient operation of churn drills, which are used to create boreholes for various purposes, such as water wells, oil and gas exploration, and geothermal energy production.

1. Operating and Maintaining Churn Drills

Operate churn drills to create boreholes according to specifications.

- Set up and assemble churn drills.

- Install and maintain drill bits.

- Monitor drilling progress and make adjustments as needed.

2. Sample Collection and Testing

Collect soil and rock samples from boreholes.

- Identify and classify soil and rock samples.

- Conduct basic geological tests on samples.

3. Equipment Maintenance and Repairs

Inspect and maintain churn drills and related equipment.

- Perform minor repairs and adjustments.

- Lubricate and clean equipment.

- Order and replace parts as needed.

4. Safety and Regulatory Compliance

Adhere to safety regulations and follow established procedures.

- Wear appropriate safety gear.

- Follow drilling plans and safety protocols.

- Report any incidents or hazards.

Interview Preparation Tips

To ace an interview for a Churn Drill Operator position, it is important to prepare thoroughly. Here are some tips:

1. Research the Company and Position

Take the time to learn about the company, its values, and the specific requirements of the Churn Drill Operator position.

- Visit the company website.

- Read industry news and articles.

- Contact the hiring manager for more information.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

- Focus on highlighting your skills and experience that are relevant to the position.

- Ask for feedback from a friend, family member, or career counselor.

3. Prepare Technical Questions

Expect to be asked technical questions about churn drill operation, geology, and safety protocols.

- Review drilling techniques, soil and rock classification, and safety regulations.

- Demonstrate your understanding of different types of churn drills and their applications.

- Be prepared to discuss your experience with equipment maintenance and troubleshooting.

4. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving at the interview on time.

- Wear business casual attire.

- Arrive 15-20 minutes early to show your interest and respect.

- Bring a copy of your resume and any relevant certifications or training.

Next Step:

Now that you’re armed with the knowledge of Churn Drill Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Churn Drill Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini