Are you gearing up for a career in Foundation Drill Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Foundation Drill Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

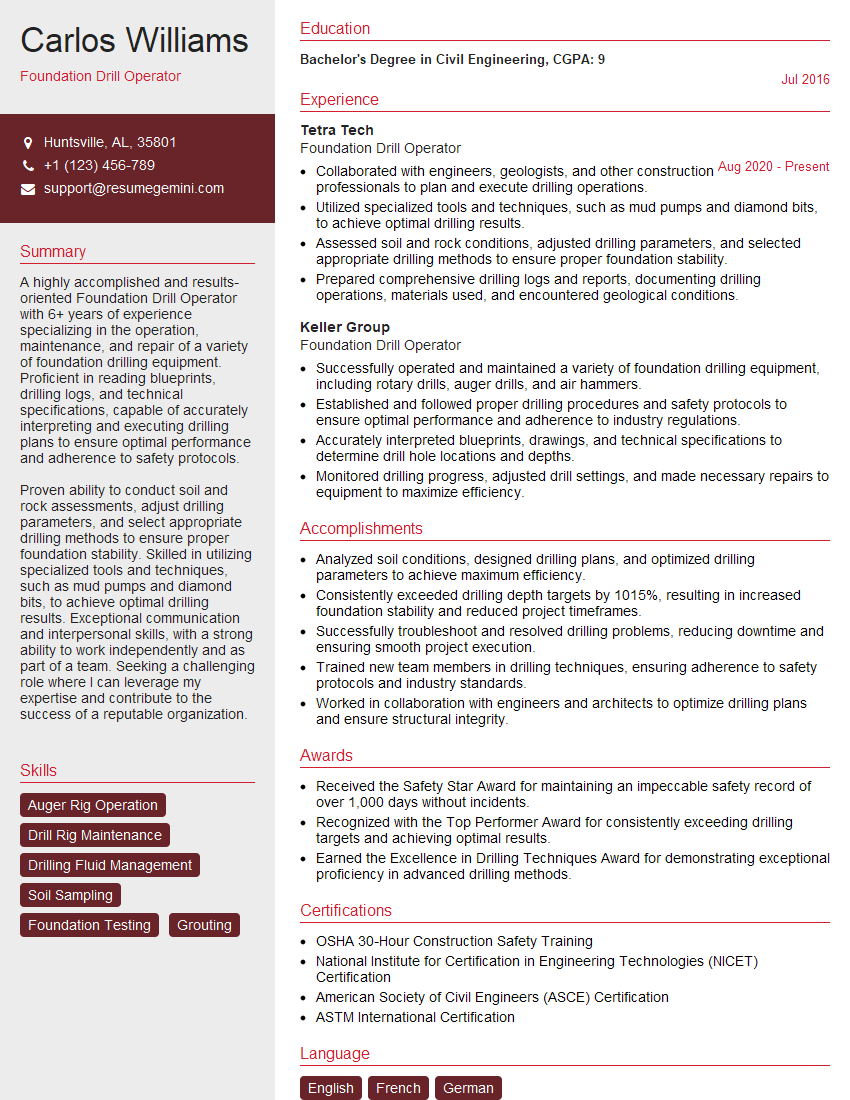

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundation Drill Operator

1. What are your responsibilities as a Foundation Drill Operator?

As a Foundation Drill Operator, my key responsibilities include:

- Operating and maintaining various drilling equipment, including hydraulic drills, augers, and core barrels

- Estimating drilling parameters such as depth, rate of penetration, and drilling fluid circulation

- Monitoring drilling operations and identifying any potential problems or hazards

- Ensuring compliance with safety regulations and environmental guidelines

- Preparing and maintaining drilling site records and logs

2. How do you ensure the accuracy of drilling depth and alignment during foundation drilling?

Equipment Calibration

- Calibrating all drilling equipment, including depth gauges and laser alignment systems

- Checking for any deviations or malfunctions

Monitoring and Adjustment

- Continuously monitoring drilling progress and comparing it to design specifications

- Making necessary adjustments to drilling parameters, such as speed, torque, and pressure

Record Keeping

- Maintaining accurate drilling logs, including depth measurements, alignment data, and any deviations

- Using this data to verify drilling accuracy and compliance with project specifications

3. Describe the different types of drilling fluids used in foundation drilling and their applications.

There are several types of drilling fluids used in foundation drilling, each with specific applications:

- Water-based fluids: Commonly used in stable soil conditions, they provide cooling and lubrication to the drilling tools.

- Bentonite-based fluids: Used in unstable or soft soil formations, they form a protective layer on the borehole walls to prevent collapse.

- Polymer-based fluids: These fluids are used in challenging conditions, such as high temperatures or the presence of hydrocarbons, as they offer superior stability and lubrication.

- Air: In certain applications, compressed air can be used as a drilling fluid to remove cuttings and cool the drilling tool.

4. How do you handle potential hazards and emergencies during foundation drilling operations?

Risk Assessment and Mitigation

- Identifying potential hazards, such as ground collapse, equipment failure, or environmental risks

- Implementing appropriate safety measures and emergency protocols

Emergency Response

- Training in emergency procedures for situations such as uncontrolled gas releases or equipment malfunctions

- Responding promptly and effectively to minimize risks to personnel, equipment, and the environment

Communication and Coordination

- Maintaining clear communication with all project stakeholders, including engineers, geologists, and site supervisors

- Coordinating efforts to ensure a safe and efficient response to emergencies

5. How do you determine the appropriate drilling method for different ground conditions?

Selecting the appropriate drilling method depends on various factors, including:

- Soil type and composition: Different drilling methods are suited for specific soil types, such as cohesive soils, granular soils, or rocky formations.

- Depth and diameter requirements: The drilling method should be capable of reaching the desired depth and creating the required borehole diameter.

- Environmental considerations: Some drilling methods, such as dry drilling, may pose environmental concerns and require special precautions.

- Equipment availability: The availability and capabilities of drilling equipment, such as drill rigs and cutting tools, influence the choice of drilling method.

6. Describe the steps involved in preparing a drilling site for foundation construction.

Site Preparation

- Establishing the drilling grid and marking drilling locations

- Clearing the site of vegetation, debris, and any obstructions

- Ensuring proper access for drilling equipment and materials

Excavation and Leveling

- Excavating shallow pits or platforms for drilling rig placement

- Leveling the drilling area to ensure stability and prevent equipment damage

- Installing temporary platforms or mats for equipment support and worker safety

Utilities and Safety

- Locating and marking existing utilities to avoid damage

- Implementing safety measures such as barricades, warning signs, and personal protective equipment

- Ensuring proper ventilation and dust control

7. What are the key factors to consider when selecting drilling tools and equipment?

Drill Type and Capacity

- Matching the drill type (e.g., rotary, percussion) to the drilling method and ground conditions

- Selecting drills with appropriate capacity for the required drilling depth and diameter

Cutting Tools

- Choosing cutting tools (e.g., bits, augers, core barrels) suitable for the soil type and drilling method

- Selecting the appropriate material and design for the specific application

Equipment Condition and Maintenance

- Using well-maintained and calibrated equipment to ensure optimal performance

- Inspecting and servicing equipment regularly according to manufacturer’s recommendations

8. How do you interpret drilling logs and identify geological formations?

Log Analysis

- Examining drilling logs for information such as soil type, color, density, and moisture content

- Identifying patterns and changes in the log data to determine geological formations

Geological Knowledge

- Utilizing knowledge of local geology and stratigraphy to interpret drilling logs

- Correlating drilling data with geological maps and other available information

Communication and Reporting

- Documenting findings and interpretations in drilling reports

- Communicating geological information to engineers, geologists, and other project stakeholders

9. Describe your experience with performing soil sampling and testing during foundation drilling.

Sampling Techniques

- Using various soil sampling methods, such as split-spoon samplers and Shelby tubes

- Collecting samples at designated depths or according to geological changes

Testing and Analysis

- Performing field tests, such as standard penetration tests (SPT) and vane shear tests

- Sending samples to laboratories for detailed analysis, such as grain size distribution and shear strength testing

Data Interpretation

- Analyzing soil test results to assess soil properties and geotechnical characteristics

- Providing recommendations for foundation design and construction based on soil test data

10. How do you ensure the quality of your work and maintain high standards of drilling operations?

Quality Control Procedures

- Following established quality control protocols for all drilling activities

- Documenting drilling parameters, equipment calibration, and any deviations from specifications

Equipment Maintenance and Calibration

- Performing regular equipment inspections and maintenance to ensure accuracy and reliability

- Calibrating all equipment according to manufacturer’s specifications and industry standards

Continuous Improvement

- Seeking opportunities to enhance skills and knowledge through training and professional development

- Participating in industry events and staying up-to-date with best practices

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundation Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundation Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foundation Drill Operators are entrusted with the responsibility of operating heavy equipment to excavate and create holes in the ground for the installation of building foundations, utility poles, and other structures. Their primary duties involve:

1. Equipment Operation

Skilled in operating foundation drilling equipment, including hydraulic drills, augers, and rotary hammers

- Ensures equipment is in optimal working condition by conducting routine maintenance and inspections

- Selects appropriate drill bits and attachments based on soil conditions and project requirements

2. Hole Excavation

Precisely excavates holes to specified depths and diameters, ensuring stability and structural integrity

- Evaluates soil conditions and determines the most efficient drilling method

- Monitors drilling progress and adjusts techniques as needed to maintain hole quality and prevent collapse

3. Safety and Compliance

Prioritizes safety by adhering to established regulations and guidelines

- Conducts site inspections to identify potential hazards and implement safety measures

- Wears appropriate personal protective equipment (PPE), including gloves, goggles, and hard hat

4. Communication and Teamwork

Collaborates effectively with engineers, architects, and other construction professionals

- Interprets blueprints and specifications to ensure accurate drilling operations

- Communicates project updates, challenges, and safety concerns to the project manager

- Works harmoniously with other crew members to complete drilling tasks efficiently

Interview Tips

To excel in a Foundation Drill Operator interview, it is crucial to showcase your technical skills, safety consciousness, and ability to work effectively in a team environment.

1. Highlight Your Equipment Proficiency

Emphasize your expertise in operating various types of foundation drilling equipment. Provide specific examples of projects where you successfully utilized your skills to complete drilling tasks.

- Mention your experience in selecting and using appropriate drill bits for different soil conditions

- Discuss your ability to troubleshoot and resolve equipment issues to minimize downtime

2. Demonstrate Your Safety Knowledge

Convey your commitment to safety by describing your understanding of industry regulations and best practices. Highlight your experience in conducting site assessments and implementing risk management strategies.

- Provide examples of your involvement in safety training or certification programs

- Explain how you ensure the proper maintenance and inspection of drilling equipment

3. Emphasize Your Teamwork Skills

Describe your ability to collaborate effectively with other team members. Share experiences where you coordinated drilling operations with engineers, architects, or construction workers.

- Highlight your communication skills and ability to resolve conflicts or challenges

- Emphasize your willingness to contribute to a positive and productive work environment

4. Seek Clarification and Ask Questions

During the interview, don’t hesitate to ask questions about the specific requirements of the role and the company’s expectations. This demonstrates your interest and eagerness to learn.

- Inquire about the types of projects you would be involved in

- Ask about the safety protocols and training opportunities available

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Foundation Drill Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Foundation Drill Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.