Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Driller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

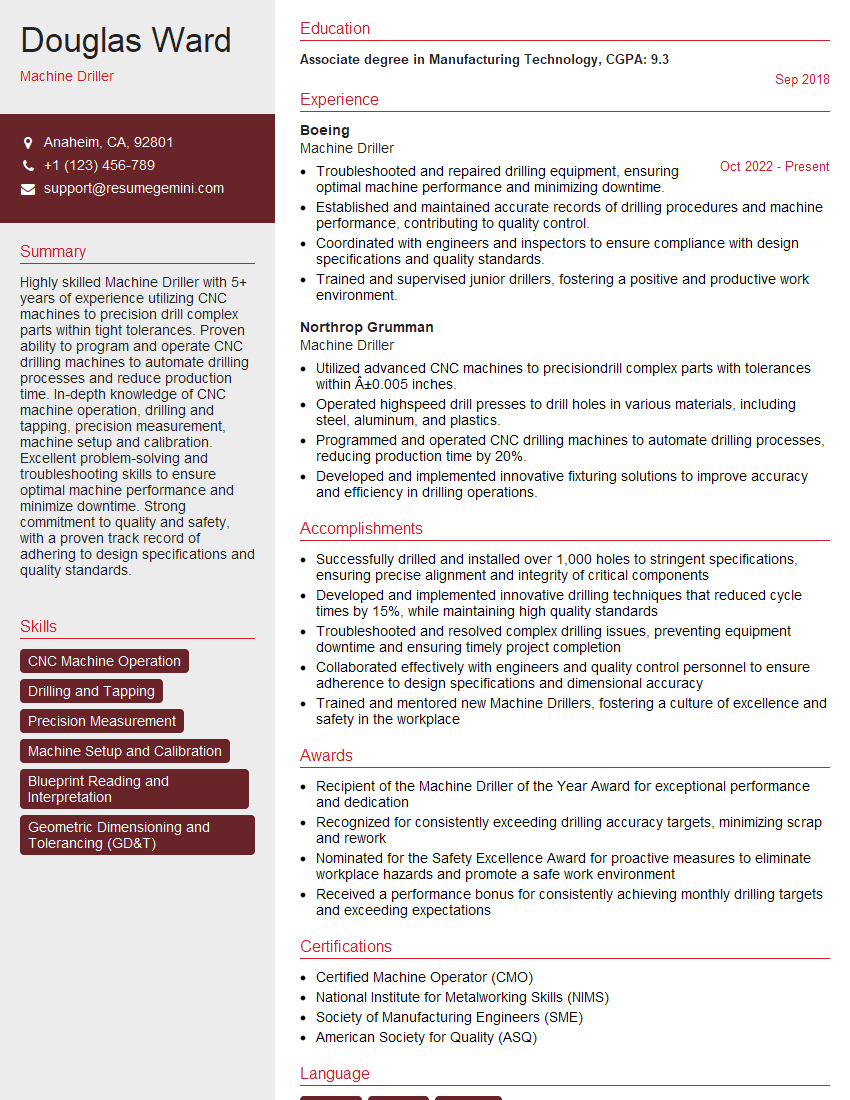

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Driller

1. What are the different types of drilling machines, and which one would you use for a particular task?

There are various types of drilling machines, each designed for specific tasks. Some common types include:

- Radial drilling machine: Used for drilling large holes in heavy workpieces, offering a wider range of motion.

- Upright drilling machine: Suitable for general-purpose drilling operations, featuring a fixed drill head that moves vertically.

- Sensitive drilling machine: Used for precision drilling, allowing for precise control over the drilling depth and feed rate.

- Gang drilling machine: Used for drilling multiple holes simultaneously, increasing productivity.

- Horizontal boring machine: Used for drilling large holes on large workpieces, providing high accuracy and precision.

The selection of a drilling machine for a particular task depends on factors such as the material being drilled, hole size, depth, and required accuracy.

2. How do you calculate the speed and feed rate for a drilling operation?

The speed and feed rate are crucial parameters in drilling operations. Here’s how to calculate them:

Calculating Speed

- Formula: Cutting speed = π × drill diameter × rpm / 12

Calculating Feed Rate

- Formula: Feed rate = cutting speed × chip load per tooth

The chip load per tooth is typically provided by the drill manufacturer based on the material being drilled.

3. What are the common types of drill bits, and when would you use each type?

There are numerous types of drill bits, each designed for specific materials and applications:

- Twist drill bit: General-purpose bit used for drilling in most materials.

- Carbide drill bit: Used for drilling hard materials such as steel and cast iron.

- Brad point drill bit: Used for creating precise holes, often for woodworking.

- Step drill bit: Used for drilling holes of various diameters in one operation.

- Hole saw: Used for cutting large holes in thin materials.

The selection of a drill bit depends on the material being drilled and the desired hole size and shape.

4. How do you inspect and maintain a drilling machine?

Regular inspection and maintenance are essential for ensuring the accuracy and longevity of a drilling machine:

- Inspection: Inspect the machine for any visible damage, loose parts, or excessive wear. Check the chuck for proper alignment and tightness.

- Maintenance: Clean the machine regularly, lubricate moving parts, and replace worn or damaged components as needed. Follow the manufacturer’s recommended maintenance schedule.

5. How do you troubleshoot common drilling problems, such as drill bit breakage or chattering?

Troubleshooting drilling problems requires a systematic approach:

- Drill bit breakage: Check for proper drill bit selection, correct speed and feed rate, and workpiece stability.

- Chattering: Ensure the drill bit is sharp, the workpiece is securely clamped, and the machine is operating at the proper speed and feed rate.

Other common problems and their solutions include:

- Hole size inaccuracies: Check drill bit diameter, machine accuracy, and workpiece alignment.

- Surface finish issues: Adjust speed and feed rate, use a lubricant, and ensure the drill bit is sharp.

6. What safety precautions should be observed when operating a drilling machine?

Safety is paramount when operating a drilling machine:

- Wear appropriate safety gear, including eye protection, gloves, and protective clothing.

- Securely clamp the workpiece to prevent movement.

- Never attempt to adjust or clean the machine while it is running.

- Use sharp drill bits and maintain proper speed and feed rates to avoid accidents.

- Follow all manufacturer’s instructions and safety guidelines.

7. How do you measure and ensure the accuracy of drilled holes?

Accurate hole measurement is crucial for precision drilling:

- Use precision measuring tools such as calipers or micrometers.

- Check hole diameter and depth against specifications.

- Inspect the hole for any irregularities or imperfections.

- Regularly calibrate measuring tools to ensure accuracy.

8. What techniques do you use to optimize drilling efficiency?

Optimizing drilling efficiency involves several techniques:

- Choose the correct drill bit and machine settings for the material and hole requirements.

- Use sharp drill bits and maintain proper lubrication.

- Secure the workpiece properly to prevent movement.

- Consider using automated drilling systems or CNC machines for high-volume production.

9. How do you handle different types of materials, such as metals, plastics, and composites?

Handling different materials requires specific techniques:

- Metals: Use appropriate drill bits and cutting fluids for different metal types.

- Plastics: Adjust speed and feed rates to prevent melting or distortion.

- Composites: Use specialized drill bits designed for composite materials.

10. What are your experiences in working with advanced drilling technologies, such as CNC drilling or laser drilling?

Advanced drilling technologies offer increased precision and efficiency:

- CNC drilling: Experience in programming and operating CNC drilling machines.

- Laser drilling: Knowledge of laser drilling principles and applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Drills are pivotal in manufacturing processes, meticulously creating holes and shaping materials to precise specifications. To excel in this role, candidates must possess a keen eye for detail, adeptness at operating complex machinery, and a commitment to safety.

1. Machine Operation and Maintenance

The Machine Driller’s primary responsibility is to skillfully operate and maintain drilling machines. This involves:

- Setting up and calibrating drilling machines to ensure optimal performance.

- Selecting appropriate drill bits and cutting tools for various materials and hole configurations.

- Monitoring drilling operations, adjusting parameters as needed to achieve desired results.

- Performing routine maintenance on drilling machines, including lubrication, cleaning, and minor repairs.

2. Quality Control and Inspection

Ensuring the precision and quality of drilled parts is paramount. Machine Drillers conduct thorough inspections:

- Measuring and verifying hole dimensions, tolerances, and surface finishes.

- Identifying and correcting any deviations from specifications.

3. Material Handling

Machine Drillers often handle materials, including:

- Loading and unloading workpieces onto drilling machines.

- Positioning materials for precise drilling operations.

4. Safety Protocols

Adhering to safety regulations is essential. Machine Drillers:

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Follow established safety procedures when operating drilling machines.

- Maintain a clean and organized work area.

Interview Tips

Preparing for a Machine Driller interview requires a combination of technical knowledge and presentation skills. Use these tips to ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Understanding the specific requirements of the Machine Driller role will help you tailor your responses and highlight your qualifications.

2. Highlight Your Technical Expertise

Demonstrate your proficiency in operating drilling machines, including different types, capabilities, and safety protocols. Quantify your accomplishments, providing specific examples of how you have achieved success.

3. Emphasize Quality and Precision

Stress your commitment to delivering high-quality results. Explain your understanding of quality standards and inspection procedures. Provide examples of how you have identified and resolved deviations from specifications.

4. Practice Safety Knowledge

Convey your understanding of safety regulations and your commitment to maintaining a safe work environment. Highlight your experience in following established safety protocols and operating drilling machines in a responsible manner.

5. Show Enthusiasm and Motivation

Express your passion for the manufacturing industry and your desire to contribute to the company’s success. Share your goals and aspirations, demonstrating your commitment to growth and learning.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Machine Driller, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Machine Driller positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.