Feeling lost in a sea of interview questions? Landed that dream interview for Industrial X-Ray Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Industrial X-Ray Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

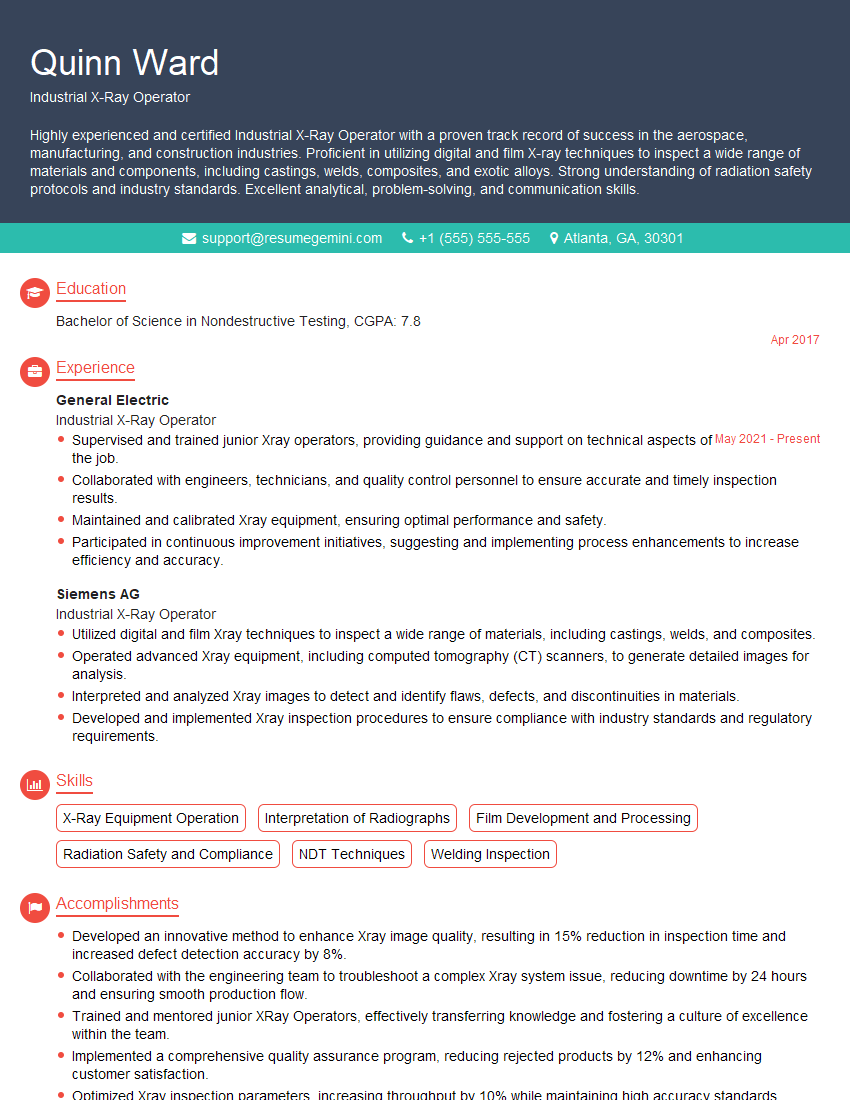

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial X-Ray Operator

1. What are the different types of industrial X-ray equipment and their applications?

- Portable X-ray machines: Used for on-site inspections, such as in construction and maintenance.

- Fixed X-ray machines: Used in factories and laboratories for quality control and research purposes.

- Computed tomography (CT) scanners: Used to create 3D images of objects for detailed analysis.

2. Explain the principles and techniques used in industrial X-ray inspection.

Radiation generation

- High-energy electrons strike a metal target, producing X-rays.

Interaction with materials

- X-rays pass through objects, interacting differently with different materials.

- Denser materials absorb more radiation, while less dense materials allow more radiation to pass through.

Image formation

- The resulting radiation is captured on a detector, such as a film or digital sensor.

- The detected radiation forms an image that represents the internal structure and density of the object.

3. Describe the safety precautions that must be observed when working with industrial X-ray equipment.

- Wear appropriate personal protective equipment (PPE), such as lead aprons and gloves.

- Stay behind barriers or in designated safe areas.

- Monitor radiation levels and follow established safety limits.

- Undergo regular medical examinations to ensure health and safety.

4. What are the common defects that can be detected using industrial X-ray inspection?

- Cracks

- Voids

- Inclusions

- Corrosion

- Weld defects

5. What techniques can be used to improve the quality of industrial X-ray images?

- Selecting the appropriate X-ray energy level and detector type.

- Using filtration to reduce scatter radiation.

- Employing image enhancement techniques to improve contrast and detail.

6. Describe the different types of X-ray image analysis methods.

- Qualitative analysis: Visual evaluation of images to identify defects and anomalies.

- Quantitative analysis: Measurement of specific parameters, such as crack length or thickness, using specialized software.

7. How do you interpret industrial X-ray images to assess the integrity of materials and components?

- Identify and classify defects based on their appearance and location.

- Determine the severity of defects and their potential impact on performance.

- Make recommendations for corrective actions or further inspection.

8. What are the current trends and advancements in industrial X-ray technology?

- Digital radiography: Use of digital detectors and software for improved image quality and efficiency.

- Computed tomography (CT): Creation of 3D models for more detailed analysis.

- Artificial intelligence (AI): Automated image analysis and defect detection.

9. How do you stay up-to-date on the latest developments and best practices in industrial X-ray inspection?

- Attend industry conferences and workshops.

- Read technical articles and journals.

- Seek training and certification from reputable organizations.

10. Describe a challenging industrial X-ray inspection project you have worked on. How did you approach it and what was the outcome?

- Explain the specific challenge encountered.

- Describe the steps taken to overcome the challenge.

- Highlight the results and impact of the inspection.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial X-Ray Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial X-Ray Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial X-Ray Operators possess expertise in operating and maintaining industrial X-ray systems. They ensure the safe and efficient production of high-quality radiographs for various industrial applications.

1. X-Ray Examination

Conduct thorough X-ray examinations on diverse materials and components, including castings, welds, composites, and various industrial machinery.

2. Equipment Setup and Maintenance

Set up and configure industrial X-ray equipment according to specific requirements. Perform regular maintenance and calibration to ensure optimal performance and accuracy.

3. Image Analysis and Interpretation

Analyze and interpret radiographic images to detect and identify flaws, defects, or anomalies within materials or components.

4. Quality Assurance and Compliance

Ensure the quality and accuracy of radiographic examinations through adherence to established standards and industry best practices. Maintain compliance with regulatory requirements related to radiation safety.

Interview Tips

Preparing for an interview as an Industrial X-Ray Operator requires careful consideration of the key responsibilities and demonstrating your expertise in the field. Here are some tips and preparation hacks to help you ace the interview.

1. Research the Company and Position

Thoroughly research the company you are interviewing with and the specific job position. Familiarize yourself with their products, services, and industry standing. This will demonstrate your interest and understanding of the company’s operations.

2. Highlight Your Technical Skills

Emphasize your technical proficiency in X-ray examination, equipment operation, and image analysis. Provide specific examples of your skills and expertise, quantifying your accomplishments whenever possible.

3. Prepare for Technical Questions

Expect to encounter technical questions related to X-ray principles, equipment maintenance, and image interpretation. Review basic X-ray physics, equipment specifications, and common industry standards to prepare for these questions.

4. Showcase Your Problem-Solving Abilities

Interviewers often seek candidates with excellent problem-solving skills. Describe instances where you successfully identified and resolved issues related to X-ray operations or image analysis. Highlight your analytical thinking and decision-making abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial X-Ray Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!