Are you gearing up for an interview for a Rock Drill Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rock Drill Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

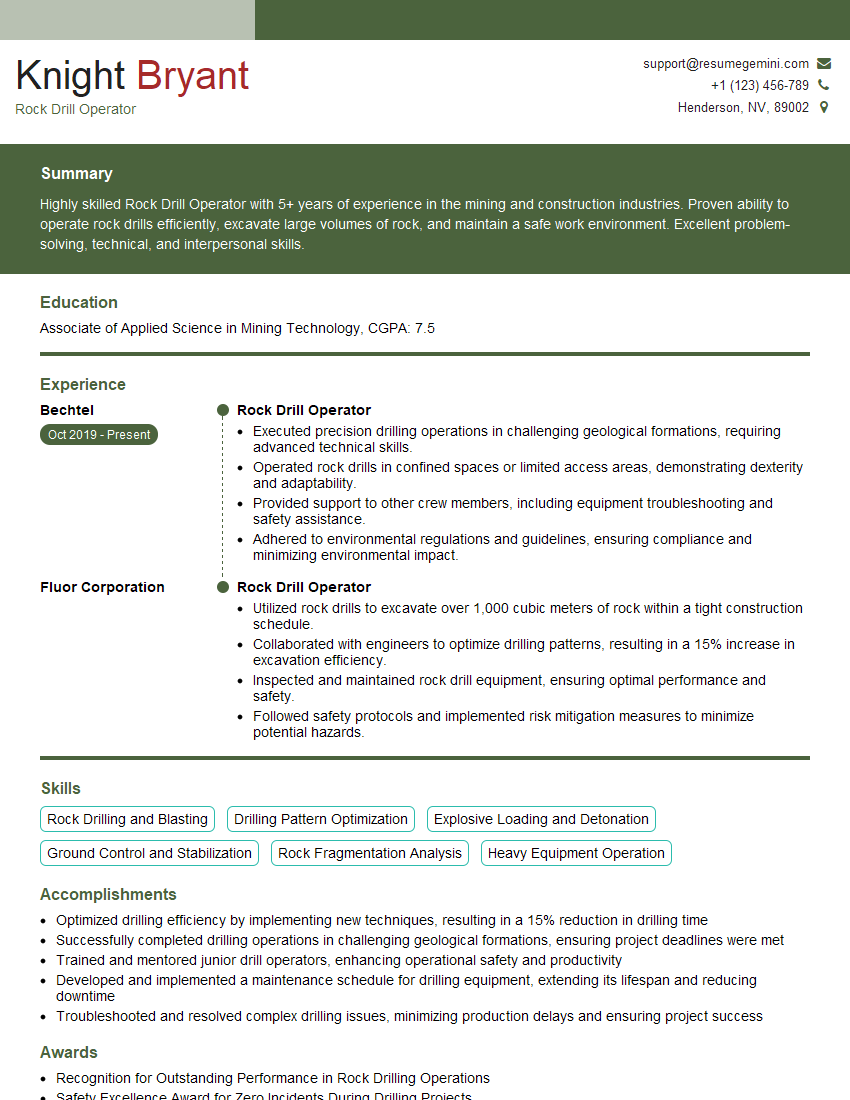

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rock Drill Operator

1. Describe the different types of rock drills and their uses?

There are various types of rock drills, each designed for specific applications:

- Jackhammers: Handheld drills used for breaking concrete, excavating trenches, and mining.

- Drifters: Mounted drills used for drilling holes in underground mines and tunnels.

- Tophammers: Drills mounted on a boom or mast, used for surface mining and construction.

- Down-the-hole (DTH) hammers: Rotary drills used for drilling deep holes in mining and oil exploration.

2. What are the safety precautions to be taken when operating a rock drill?

General Precautions

- Wear proper protective gear (hard hat, safety glasses, gloves).

- Inspect the drill and ensure it’s in good working condition.

- Establish a safe work area.

Operational Precautions

- Maintain a firm grip and control the drill’s movement.

- Secure the drill against rotation.

- Use the correct drilling technique to avoid kickbacks and injuries.

3. How do you maintain a rock drill to ensure optimal performance?

Regular maintenance is crucial to extend the drill’s life and ensure efficiency:

- Daily: Inspect drill for leaks, damage, and loose connections.

- Weekly: Clean and lubricate the drill’s moving parts. Check air or hydraulic systems.

- Monthly: Perform a thorough inspection, including testing controls and safety features.

- Scheduled: Major overhauls and repairs may be required periodically, depending on usage.

4. What are the common problems encountered while operating a rock drill and how do you troubleshoot them?

Some common issues and troubleshooting steps include:

- Drill not starting: Check power supply, air pressure, or hydraulic fluid levels.

- Slow drilling: Check for dull bits, clogged air lines, or insufficient lubrication.

- Excessive vibration: Inspect the drill for loose bolts, damaged bearings, or unbalanced bits.

- Air leaks: Identify and tighten any loose connections or replace damaged hoses.

5. How do you calculate the drilling time for a specific task?

To calculate drilling time, consider the following factors:

- Drill type and efficiency: Determine the rate of penetration for the drill you’re using.

- Rock hardness: Harder rocks require more time to drill through.

- Hole depth and diameter: Calculate the total volume of material to be removed.

- Environmental factors: Account for potential delays due to weather or ground conditions.

6. What are the different methods for positioning a rock drill for accurate drilling?

Positioning is crucial for accurate drilling:

- Manual positioning: Using manual controls or handles to guide the drill.

- Automated positioning: Using sensors or laser guidance to align the drill precisely.

- Template or jig: Creating a physical guide to ensure consistent hole placement.

7. How do you ensure safety when working around other equipment and personnel?

Safety is paramount in a shared work environment:

- Maintain a clear work area: Keep the area free from obstacles and tripping hazards.

- Communicate with others: Clearly communicate intentions and movements to avoid accidents.

- Establish safe work zones: Designate areas for different tasks to minimize interference.

- Use warning signals: Utilize horns, lights, or hand signals to alert others of potential hazards.

8. How do you measure drilling productivity and efficiency?

Productivity and efficiency can be measured through various metrics:

- Footage drilled per hour: Calculates the total length of holes drilled in a given time frame.

- Drilling rate: Determines the speed at which the drill penetrates the rock, expressed in feet per minute.

- Cost per foot drilled: Assesses the financial efficiency of drilling operations, considering labor, equipment, and materials.

9. What is the importance of proper bit selection for different rock types?

Bit selection directly affects drilling performance:

- Matching bit type: Different bits are designed for specific rock formations (e.g., button bits for hard rock, cross bits for soft rock).

- Bit diameter: Choosing the appropriate diameter ensures hole size accuracy and drilling efficiency.

- Bit wear and maintenance: Regular bit inspection and sharpening are essential to maintain optimal drilling performance.

10. Describe the environmental considerations and regulations when operating a rock drill?

Environmental compliance is crucial:

- Noise pollution: Minimize noise levels by using silencers or enclosures.

- Dust control: Implement dust suppression systems to reduce air pollution.

- Water usage: Use water judiciously and consider recycling options.

- Waste management: Dispose of drilling cuttings and used bits responsibly according to regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rock Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rock Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rock Drill Operators are responsible for operating rock drills to extract rock and minerals from the earth. They work in a variety of settings, including mines, quarries, and construction sites. Their key responsibilities include:

1. Drilling Holes

Rock Drill Operators use rock drills to bore holes into rock. The size and depth of the holes will vary depending on the project. The operator must be able to accurately control the drill to ensure that the holes are drilled to the correct specifications.

- Operate rock drills to bore holes into rock

- Control the drill to ensure that the holes are drilled to the correct specifications

2. Explosives Handling

In some cases, Rock Drill Operators may be required to handle explosives. They must be trained in the safe handling and storage of explosives. They must also be able to follow the instructions of a blasting supervisor.

- Handle explosives in a safe manner

- Follow the instructions of a blasting supervisor

3. Equipment Maintenance

Rock Drill Operators are responsible for maintaining their equipment. They must be able to troubleshoot problems and make repairs as needed. They must also keep their equipment clean and in good working order.

- Maintain equipment in good working order

- Troubleshoot problems and make repairs as needed

- Keep equipment clean

4. Safety

Rock Drill Operators work in a hazardous environment. They must be aware of the potential hazards and take precautions to avoid injury.

- Follow safety procedures

- Wear appropriate safety gear

- Be aware of potential hazards

Interview Tips

Preparing for a job interview can be nerve-wracking, but there are steps you can take to improve your chances of success.

1. Research the Company

Take some time to learn about the company you’re interviewing with. This will help you understand their culture, values, and goals. It will also help you answer questions about why you’re interested in the position.

- Visit the company’s website

- Read news articles about the company

- Talk to people who work for the company

2. Practice Your Answers

Once you’ve researched the company, start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Use the STAR method to answer questions

- Practice with a friend or family member

- Record yourself answering questions

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you’re interviewing for.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing strong perfumes or colognes

4. Be On Time

Punctuality is important, so make sure you arrive for your interview on time. This shows that you’re respectful of the interviewer’s time and that you’re serious about the position.

- Plan your route ahead of time

- Allow extra time for traffic or unforeseen delays

- If you’re running late, call the interviewer to let them know

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rock Drill Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!