Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tunneling Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

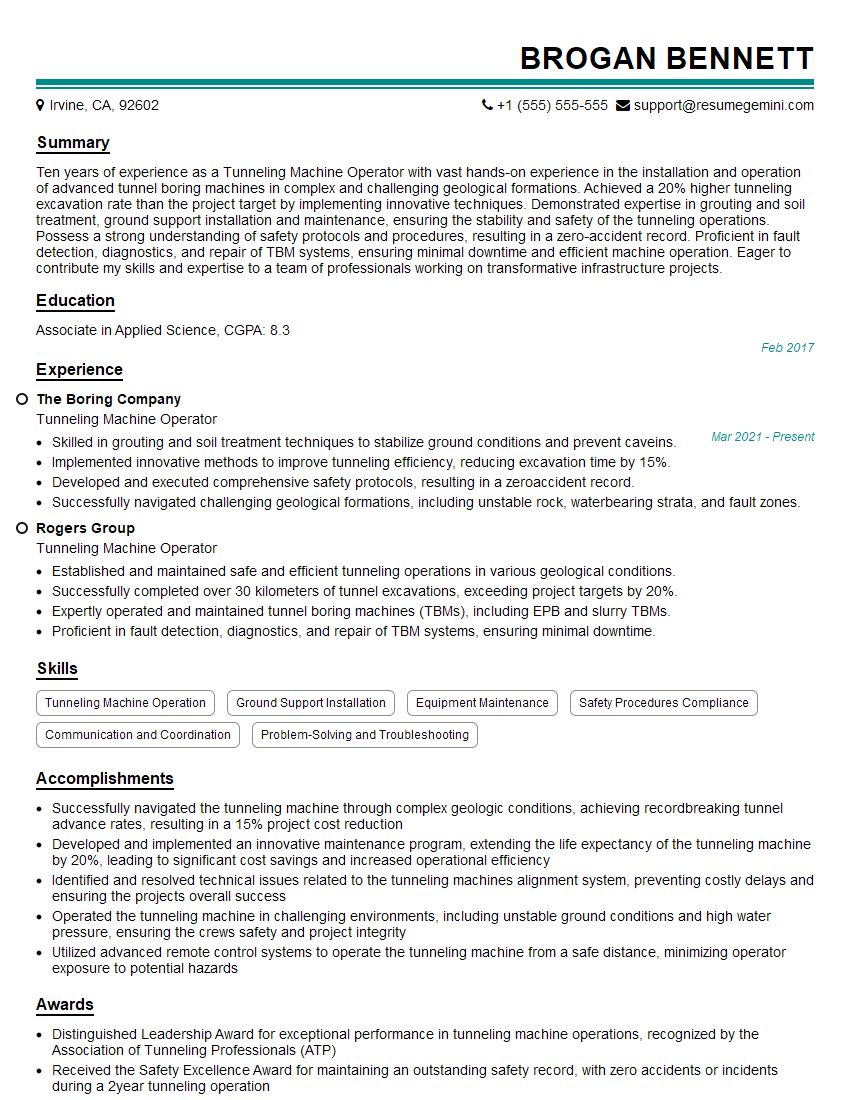

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tunneling Machine Operator

1. Describe the major components of a tunnel boring machine (TBM)?

- Cutterhead: The rotating head that excavates the ground, armed with cutters.

- Shield: Supports the excavated area, provides stability, and houses the TBM components.

- Gripper system: Clamps onto the tunnel lining, providing thrust and advancing the TBM.

- Conveyor belt: Transports excavated material from the cutterhead to the rear.

- Electric or diesel engine: Powers the TBM’s operations.

2. What are the key parameters to consider when selecting a TBM for a particular tunneling project?

Ground conditions:

- Soil or rock type

- Water table level

- Presence of boulders or obstacles

Tunnel design:

- Diameter and length

- Required lining

- Depth and alignment

Project requirements:

- Cost

- Timeline

- Environmental impact

3. Explain the different methods used for tunnel lining installation?

- Segmental lining: Precast concrete segments bolted together to form the tunnel wall.

- Shield tunneling: The TBM installs the tunnel lining as it advances, using a shield to support the ground.

- Drill-and-blast: Excavation using explosives, followed by lining installation.

- Jet grouting: Soil stabilization using high-pressure grout injections, creating a tunnel lining.

4. How do you ensure the safety of the TBM crew during tunneling operations?

- Regular inspections and maintenance

- Ventilation and air quality monitoring

- Emergency escape and communication systems

- Training and certification of operators

- Ground support and monitoring

5. Describe the steps involved in the launch and retrieval of a TBM?

Launch:

- Excavate a launch pit

- Assemble the TBM components

- Lower the TBM into the launch pit

Retrieval:

- Excavate a retrieval pit

- Drive the TBM into the retrieval pit

- Disassemble the TBM components

6. What are the potential hazards associated with TBM operations and how do you mitigate them?

- Ground collapse: Use ground support systems, monitoring, and risk assessments.

- Gas leaks: Provide adequate ventilation and gas detection systems.

- Equipment failures: Regular inspections, maintenance, and redundancy measures.

- Fire: Fire suppression systems, training, and emergency procedures.

- Flooding: Waterproofing measures, drainage systems, and contingency plans.

7. How do you monitor and control the alignment and grade of the TBM during tunneling?

- Laser guidance systems

- Total station surveys

- Inclinometers

- Monitoring and adjustment of steering systems

- Regular data analysis and reporting

8. Explain the role of instrumentation and data acquisition systems in TBM operations?

- Monitoring ground conditions (stress, pressure, water levels)

- Tracking TBM parameters (cutterhead rotation, thrust, torque)

- Collecting data for safety and risk assessments

- Optimizing TBM performance and efficiency

- Providing early warning of potential issues

9. How do you handle unexpected ground conditions during tunneling?

- Conduct thorough ground investigation

- Develop contingency plans for various scenarios

- React quickly and adjust TBM parameters and ground support systems

- Consult with geotechnical experts and engineers

- Implement safety measures and ensure crew protection

10. Describe your experience in managing a TBM crew and coordinating with other project stakeholders?

- Leadership and team management skills

- Communication and coordination with engineers, geologists, surveyors, and support staff

- Delegation of tasks and responsibilities

- Conflict resolution and decision-making

- Health, safety, and environmental management

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tunneling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tunneling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tunneling Machine Operators are responsible for operating and maintaining Tunnel Boring Machines (TBMs) used in the construction of tunnels for transportation, utilities, and other underground infrastructure projects.

1. Machine Operation

Operate TBMs according to established plans and specifications.

- Control the TBM’s cutting head rotation, thrust, and steering.

- Monitor and adjust machine parameters to ensure optimal performance and safety.

2. Maintenance and Troubleshooting

Perform routine maintenance and repairs on TBMs.

- Inspect and replace worn or damaged components.

- Diagnose and resolve mechanical, electrical, and hydraulic issues.

3. Safety Management

Follow established safety protocols and procedures.

- Wear appropriate personal protective equipment (PPE).

- Monitor tunnel conditions and take appropriate measures to mitigate risks.

4. Communication and Coordination

Communicate with engineers, supervisors, and other team members.

- Provide updates on machine status and progress.

- Coordinate with other trades involved in the tunneling project.

Interview Tips

Preparing for a Tunneling Machine Operator interview requires a combination of technical knowledge and effective interview skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, projects, and industry reputation. Research the specific TBM model you will be operating and its technical capabilities.

- Use the company website, industry publications, and LinkedIn to gather information.

- Identify the keywords in the job description and tailor your resume and cover letter accordingly.

2. Highlight Your Technical Expertise

Emphasize your experience and skills in operating TBMs, including your understanding of machine mechanics and electrical systems. Provide specific examples of projects where you successfully operated and maintained TBMs.

- Quantify your accomplishments using metrics such as footage excavated or hours of operation.

- Be prepared to discuss your troubleshooting abilities and how you resolved complex machine issues.

3. Showcase Your Safety Mindset

Safety is paramount in tunneling operations. Demonstrate your commitment to following safety protocols and procedures. Highlight your understanding of potential hazards and your experience in implementing risk mitigation measures.

- Provide examples of your involvement in safety training or initiatives.

- Discuss your approach to hazard identification and risk assessment.

4. Emphasize Your Communication Skills

Effective communication is crucial in a team environment. Describe your ability to communicate clearly and concisely with engineers, supervisors, and other team members.

- Provide examples of successful communication in challenging or time-sensitive situations.

- Discuss your experience in providing technical updates and cooperating with other trades.

5. Practice and Prepare

Prepare for common interview questions by practicing your responses. Anticipate questions related to your technical expertise, safety awareness, and communication skills. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Conduct mock interviews with a friend, family member, or career counselor.

- Research the company’s values and prepare questions that demonstrate your alignment with their culture.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tunneling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!