Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Copper Miner, Blasting position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

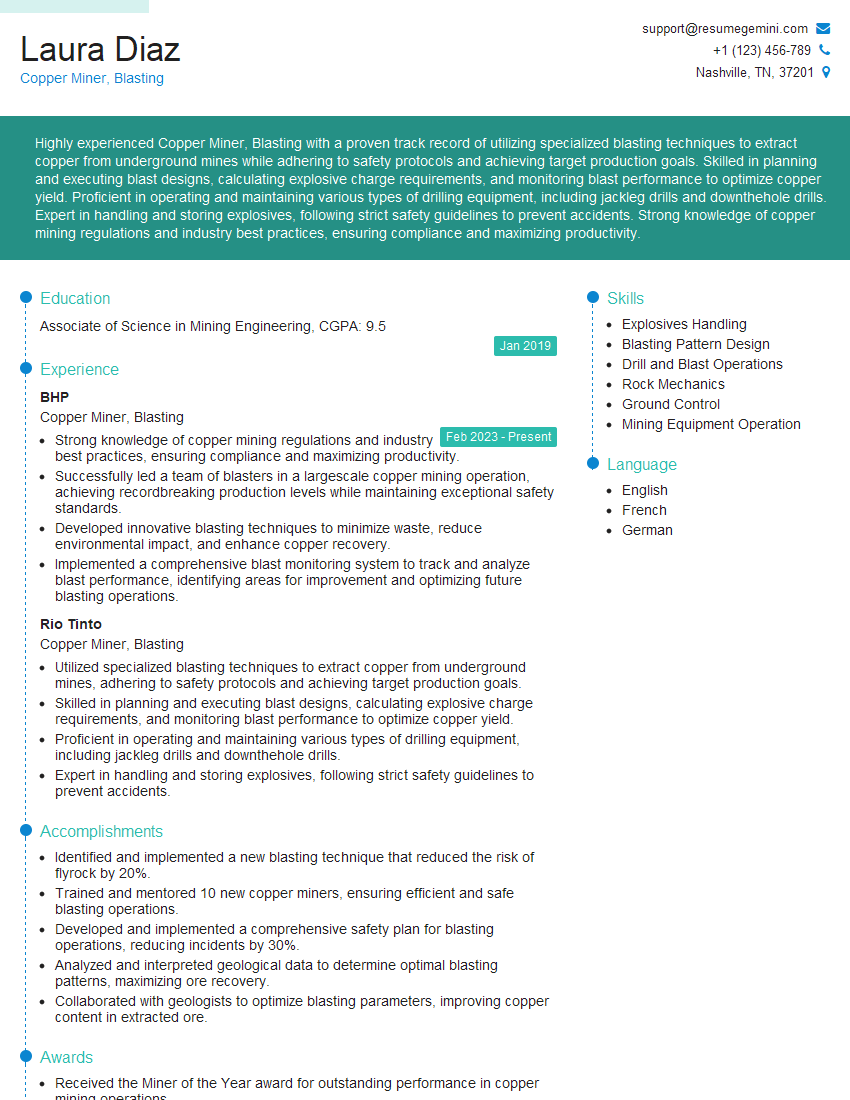

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Copper Miner, Blasting

1. What are the different types of explosives used in copper mining, and what are their advantages and disadvantages?

- ANFO (ammonium nitrate/fuel oil): ANFO is the most commonly used explosive in copper mining due to its low cost and ease of handling. It is a mixture of ammonium nitrate and fuel oil, and it is detonated using a blasting cap. ANFO is relatively safe to handle, but it can be sensitive to shock and vibration.

- Emulsions: Emulsions are a type of explosive that is made from a mixture of water, oil, and ammonium nitrate. Emulsions are more powerful than ANFO, and they are less sensitive to shock and vibration. However, emulsions are also more expensive than ANFO.

- Slurries: Slurries are a type of explosive that is made from a mixture of water, ammonium nitrate, and a gelling agent. Slurries are the most powerful type of explosive used in copper mining, and they are also the most expensive. Slurries are less sensitive to shock and vibration than ANFO and emulsions.

2. What are the different types of blasting methods used in copper mining, and what are their advantages and disadvantages?

Open-pit blasting:

- Open-pit blasting is the most common type of blasting method used in copper mining. In this method, the explosive is placed in a hole that is drilled into the rock. The hole is then filled with stemming, which is a material that helps to contain the blast. The explosive is detonated using a blasting cap, and the rock is broken up by the force of the explosion.

Underground blasting:

- Underground blasting is used in mines where the copper ore is located deep underground. In this method, the explosive is placed in a hole that is drilled into the rock. The hole is then filled with stemming, and the explosive is detonated using a blasting cap. The rock is broken up by the force of the explosion, and the ore is then removed from the mine using a conveyor belt or other equipment.

3. What are the safety precautions that must be taken when blasting in a copper mine?

- All blasting operations must be supervised by a qualified blaster.

- The blasting area must be cleared of all personnel and equipment before the blast is detonated.

- The blaster must use a blasting machine to detonate the explosive.

- The blaster must use a warning system to notify people in the area that a blast is about to be detonated.

- The blaster must inspect the blasting area after the blast to ensure that there are no unexploded explosives.

4. What are the environmental impacts of blasting in a copper mine?

- Blasting can create noise pollution, which can disturb wildlife and people living near the mine.

- Blasting can create air pollution, which can contribute to smog and other respiratory problems.

- Blasting can create water pollution, which can harm aquatic life and make water unsafe for drinking.

- Blasting can also damage the landscape, which can make it less attractive for recreation and tourism.

5. What are the steps involved in planning a blast in a copper mine?

- The first step is to determine the location of the blast.

- The next step is to determine the type of explosive that will be used.

- The next step is to determine the amount of explosive that will be used.

- The next step is to determine the method of detonation.

- The final step is to prepare the blasting area.

6. What are the different types of equipment used in blasting in a copper mine?

- Drilling equipment

- Loading equipment

- Detonation equipment

- Safety equipment

7. What are the different types of training required for copper miners who work with explosives?

- Basic explosives training

- Advanced explosives training

- Safety training

- Environmental training

8. What are the different types of certification required for copper miners who work with explosives?

- Blasting certification

- Safety certification

- Environmental certification

9. What are the different types of experience required for copper miners who work with explosives?

- Experience in drilling and blasting

- Experience in handling and storing explosives

- Experience in safety and environmental procedures

10. What are the different types of skills required for copper miners who work with explosives?

- Knowledge of explosives and their properties

- Ability to follow safety and environmental procedures

- Ability to work independently and as part of a team

- Ability to solve problems

- Ability to communicate effectively

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Copper Miner, Blasting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Copper Miner, Blasting‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Copper Miner, Blasting

Copper Miners, Blasting play a crucial role in the mining industry, ensuring the safe and efficient extraction of copper. Their responsibilities include:

1. Drilling and Blasting

Operate and maintain specialized drilling and blasting equipment to create boreholes and detonate explosives, fragmenting copper-bearing rock.

- Calculate hole locations, depths, and angles using geological data.

- Prepare and load explosive charges according to safety regulations.

2. Equipment Maintenance and Repair

Perform routine maintenance and repairs on drilling and blasting equipment to ensure optimal performance and safety.

- Inspect and replace worn or damaged components.

- Troubleshoot mechanical and electrical problems.

3. Safety and Environmental Compliance

Adhere strictly to safety protocols and environmental regulations throughout all blasting operations.

- Monitor blasting areas for potential hazards.

- Implement measures to minimize environmental impact, such as dust and noise control.

4. Communication and Teamwork

Effectively communicate with supervisors, other miners, and support staff to coordinate blasting operations and ensure safety.

- Participate in safety meetings and training sessions.

- Collaborate with engineers and geologists to plan and execute blasting strategies.

Interview Preparation Tips for a Copper Miner, Blasting

To ace your interview for a Copper Miner, Blasting position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the mining company, its operations, and the specific job requirements. Understand the scale and complexity of the blasting operations.

- Visit the company website and review industry publications.

- Identify the key responsibilities and skills required for the position.

2. Highlight Relevant Experience and Skills

Emphasize your experience in drilling, blasting, and heavy equipment operation. Showcase your knowledge of blasting techniques, safety protocols, and environmental regulations.

- Quantify your accomplishments using specific examples and metrics.

- Discuss your ability to work independently and as part of a team.

3. Demonstrate Safety Consciousness

Safety is paramount in mining operations. Highlight your commitment to safety and your understanding of industry best practices.

- Describe your experience in following safety protocols and identifying potential hazards.

- Discuss your knowledge of emergency procedures and risk management strategies.

4. Be Prepared for Technical Questions

Expect technical questions related to drilling, blasting, and explosives. Prepare by reviewing common industry terms and concepts.

- Explain the different types of explosives used in mining and their applications.

- Discuss the factors that influence blasting design, such as rock properties and geological conditions.

5. Practice Your Communication Skills

Effective communication is crucial in a mining environment. Practice articulating your thoughts clearly and confidently.

- Prepare responses to common interview questions about your experience, skills, and motivation.

- Be able to explain complex technical concepts in a concise and understandable way.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Copper Miner, Blasting interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!