Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lead Miner, Blasting interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lead Miner, Blasting so you can tailor your answers to impress potential employers.

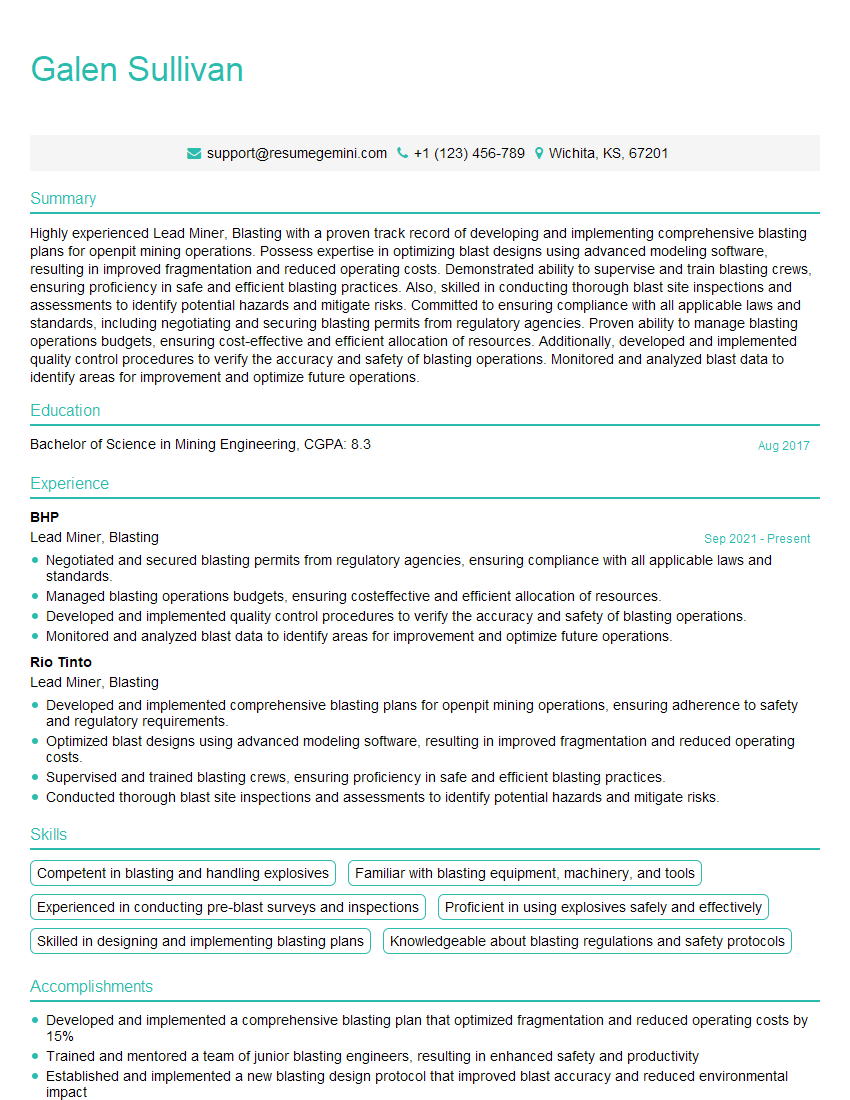

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lead Miner, Blasting

1. How do you determine the appropriate type and quantity of explosives to use for a specific blast?

To determine the appropriate type and quantity of explosives to use for a specific blast, I consider several factors, including:

- The rock type and its properties, such as hardness, density, and fracture pattern

- The desired fragmentation size

- The blasting environment, including the presence of water, gas, or other hazards

- The blasting pattern, including the hole spacing, depth, and burden

2. What are the different types of blasting caps used in mining, and when should each type be used?

There are three main types of blasting caps used in mining:

a. Electric blasting caps

- Used when precise timing is required or when there is a need for multiple blasts to be fired simultaneously

- Initiated by an electric current

b. Non-electric blasting caps

- Used when there is a risk of stray currents or when electric blasting is not feasible

- Initiated by a shock wave from a detonating cord

c. Detonating cord

- Used as a primary or secondary initiator

- Initiated by a blasting cap or another detonating cord

3. How do you calculate the charge weight and spacing for a given blast design?

To calculate the charge weight and spacing for a given blast design, I use various formulas and empirical methods, considering the following factors:

- The desired fragmentation size

- The rock type and its properties

- The blasting pattern

- The explosive type and its properties

4. What are the safety precautions that must be taken when handling and using explosives?

When handling and using explosives, I strictly adhere to safety precautions, including:

- Wearing appropriate protective gear, such as gloves, safety glasses, and earplugs

- Storing and transporting explosives in a safe and secure manner

- Following proper blasting procedures and techniques

- Inspecting equipment regularly and reporting any defects

- Maintaining a clean and organized work area

5. How do you manage and control ground vibrations from blasting operations?

To manage and control ground vibrations from blasting operations, I implement several measures, including:

- Using proper blasting techniques and explosives

- Monitoring vibration levels and adjusting blast design accordingly

- Utilizing vibration attenuation methods, such as mats or barriers

- Communicating with nearby residents and businesses to minimize disruption

6. What are the environmental impacts of blasting operations, and how can they be mitigated?

Blasting operations can have environmental impacts, including:

- Noise and vibration

- Dust and air pollution

- Water contamination

To mitigate these impacts, I implement measures such as:

- Using low-noise and low-vibration explosives

- Controlling dust and emissions through water sprays and dust collectors

- Managing water runoff to prevent contamination

- Reclaiming and revegetating blast sites

7. How do you ensure the safety of personnel and equipment during blasting operations?

To ensure the safety of personnel and equipment during blasting operations, I implement a comprehensive safety plan, including:

- Establishing clear safety protocols and procedures

- Training personnel on proper blasting techniques and safety measures

- Conducting regular safety inspections and audits

- Utilizing warning systems and exclusion zones to protect personnel

- Maintaining and inspecting equipment regularly to ensure proper functionality

8. How do you optimize blasting patterns to achieve the desired fragmentation and minimize waste?

To optimize blasting patterns and achieve the desired fragmentation and minimize waste, I consider several factors, including:

- The rock type and its properties

- The desired fragmentation size

- The blasting environment

- The available explosives and equipment

- The cost and efficiency of the blasting operation

9. How do you troubleshoot and resolve common problems encountered during blasting operations?

When encountering problems during blasting operations, I systematically troubleshoot and resolve them using the following steps:

- Identify the problem and its potential causes

- Gather data and information to analyze the situation

- Develop and test solutions to address the problem

- Implement the solution and monitor its effectiveness

- Document the problem and the resolution for future reference

10. How do you stay updated with the latest advancements and best practices in blasting technology?

To stay updated with the latest advancements and best practices in blasting technology, I engage in various activities, including:

- Attending industry conferences and workshops

- Reading technical journals and publications

- Participating in professional organizations and networking with peers

- Consulting with experts and manufacturers

- Conducting research and development projects

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lead Miner, Blasting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lead Miner, Blasting‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lead Miners, Blasting are responsible for overseeing and executing blasting operations in mining environments. They ensure that blasts are conducted safely and in compliance with regulations, while maximizing efficiency and productivity.

1. Blasting Operations Management

Supervise and manage all aspects of blasting operations, including planning, preparation, execution, and evaluation.

- Develop and implement blasting plans to optimize rock fragmentation and minimize environmental impact.

- Conduct pre-blast surveys to identify potential hazards and mitigate risks.

- Prepare and load explosives according to prescribed procedures and safety guidelines.

- Execute blasts using proper techniques and equipment, ensuring safety and efficiency.

- Monitor blast results and make adjustments as needed to achieve optimal outcomes.

2. Safety and Compliance

Maintain a safe work environment and ensure compliance with all applicable regulations and standards.

- Implement and enforce safety procedures, including proper use of personal protective equipment.

- Conduct regular safety inspections and audits to identify and address potential hazards.

- Stay up-to-date on industry best practices and regulatory changes.

- Report and investigate safety incidents and implement corrective measures to prevent recurrence.

3. Team Leadership and Training

Lead and motivate a team of miners, providing guidance and training.

- Assign tasks and responsibilities to team members and monitor their performance.

- Provide training and support to ensure team members are proficient in blasting techniques and safety procedures.

- Foster a positive and collaborative work environment.

4. Data Analysis and Improvement

Analyze blasting data and identify opportunities for improvement.

- Track and analyze blast results to identify areas for optimization.

- Recommend and implement improvements to blasting techniques and procedures.

- Use technology to enhance data collection and analysis.

Interview Tips

Preparing for an interview for the position of Lead Miner, Blasting requires thorough research and practice. Here are some tips to help you succeed:

1. Research the Company and Industry

Gather information about the mining company, its operations, and the specific role you are applying for. Understand the industry trends and challenges.

2. Highlight Your Experience and Skills

Tailor your resume and cover letter to emphasize your relevant experience in blasting operations, safety management, and team leadership. Quantify your accomplishments and provide specific examples of your contributions.

3. Practice Answering Common Interview Questions

Prepare for typical interview questions related to your technical expertise, safety practices, and leadership abilities. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide clear and concise examples.

4. Showcase Your Safety Mindset

Demonstrate your commitment to safety by highlighting your understanding of blasting regulations, your ability to identify and mitigate risks, and your experience in implementing safety procedures.

5. Be Enthusiastic and Confident

Convey your passion for the mining industry and your eagerness to contribute to the team. Show confidence in your abilities and your potential to excel in the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Lead Miner, Blasting, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Lead Miner, Blasting positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.