Are you gearing up for a career in Ore Miner, Blasting? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ore Miner, Blasting and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

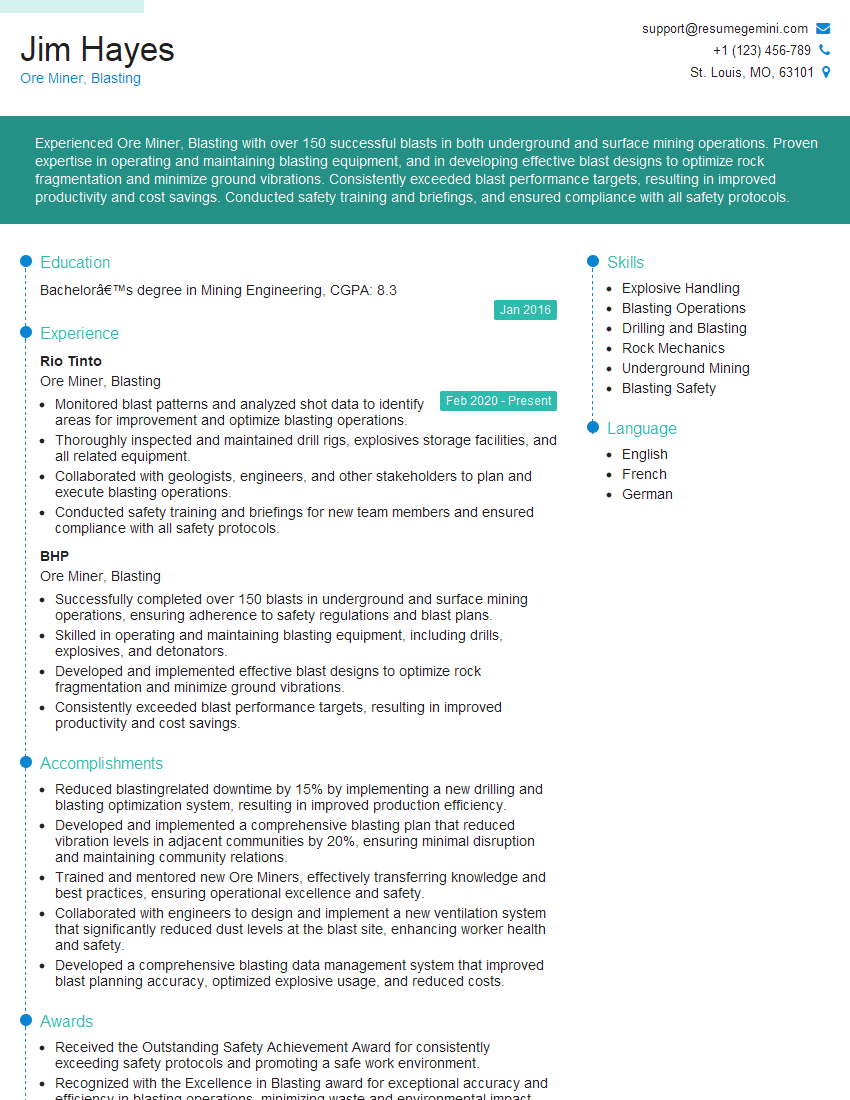

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ore Miner, Blasting

1. What are the different types of blasting techniques used in ore mining?

There are various blasting techniques employed in ore mining, each suited for specific geological conditions and ore characteristics. Some common techniques include:

- Cut and blast mining: This technique involves creating a series of cuts or slots in the ore body using shaped charges or explosives. The cuts are designed to weaken the ore, allowing it to be extracted more easily.

- Sublevel caving: This method involves creating a series of sublevels within the ore body. Explosives are placed and detonated at each sublevel, causing the ore to cave in on itself and allowing it to be collected from draw points below.

- Block caving: This technique is similar to sublevel caving but involves the caving of a large block of ore. It is typically used for large, deep, and low-grade ore deposits.

2. How do you determine the appropriate blasting pattern and explosive charge for a given ore body?

Considerations for Blasting Pattern:

- Ore body geometry and characteristics

- Rock properties (strength, density, etc.)

- Desired fragmentation size

- Ground conditions and surrounding structures

Considerations for Explosive Charge:

- Type of explosive (e.g., ANFO, emulsion, dynamite)

- Explosive strength and energy

- Hole diameter and depth

- Spacing and burden between holes

3. What safety measures are essential in ore blasting operations?

- Proper planning and design of blast patterns

- Accurate drilling and loading of explosives

- Effective ground control and rock support

- Adequate warning and evacuation procedures

- Trained and qualified blasting personnel

- Regular safety inspections and audits

4. How do you manage blast-induced ground vibrations and minimize their impact on surrounding areas?

- Careful design of blasting patterns to control vibration levels

- Use of vibration-reducing explosives and techniques (e.g., cushioned blasting)

- Monitoring and controlling blast vibration levels

- Communication with nearby residents and businesses

- Implementation of blast vibration mitigation measures (e.g., vibration mats, buffers)

5. What tools and equipment are used in ore blasting operations?

- Drilling equipment (e.g., drills, bits)

- Explosives (e.g., ANFO, emulsion, dynamite)

- Detonators and blasting caps

- Blasting wire and connectors

- Blast monitoring equipment (e.g., seismographs, accelerometers)

- Safety gear (e.g., blasting helmets, earplugs)

6. What is the role of stemming in blasting operations?

- Confines the explosive energy and directs it towards the rock

- Prevents premature detonation of the explosive

- Minimizes blast-induced air blast and noise

- Reduces ground vibration levels

7. How do you assess the effectiveness of a blasting operation?

- Evaluating fragmentation size and distribution

- Measuring blast vibration levels and comparing them to regulatory limits

- Inspecting the condition of the blast area (e.g., ground stability, damage to structures)

- Monitoring production rates and costs

- Reviewing and analyzing blasting data for continuous improvement

8. What are the environmental considerations in ore blasting operations?

- Controlling air blast and noise levels

- Minimizing dust and particulate emissions

- Protecting water resources from contamination

- Managing vibration impacts on wildlife and ecosystems

- Implementing responsible waste disposal practices

9. What are the latest technologies and trends in ore blasting operations?

- Advanced drilling and blasting techniques (e.g., precision drilling, laser-guided blasting)

- Electronic detonators and wireless blasting systems

- Blast monitoring and vibration control technologies

- Automated data collection and analysis tools

- Emphasis on environmental sustainability and responsible blasting practices

10. Describe your experience in troubleshooting and resolving blasting-related problems.

Example Outline:

- Identify the problem (e.g., excessive vibration, poor fragmentation)

- Analyze potential causes (e.g., incorrect blasting pattern, inadequate stemming)

- Develop and implement solutions (e.g., adjusting blast design, using different explosives)

- Evaluate the effectiveness of the solutions

- Document and communicate the lessons learned

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ore Miner, Blasting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ore Miner, Blasting‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ore Miners, Blasting are responsible for the safe and efficient extraction of ore from underground or surface mines. They perform a variety of tasks related to drilling, blasting, and transporting ore.

1. Drilling and Blasting

Ore Miners use specialized drilling equipment to create holes in rock formations. They then insert explosives into the holes and detonate them to break the rock into smaller pieces. This process is repeated until the ore is exposed and can be removed.

2. Loading and Transporting Ore

Once the ore is exposed, Ore Miners use heavy machinery to load it into trucks or other vehicles for transport to processing facilities. They may also be responsible for maintaining and repairing the equipment they use.

3. Safety and Environmental Compliance

Ore Miners must adhere to strict safety and environmental regulations. They wear protective gear and follow established procedures to minimize risks to themselves and others. They also work to protect the environment by following proper waste disposal and spill prevention measures.

4. Communication and Teamwork

Ore Miners work in teams and communicate regularly with other miners, supervisors, and engineers. They need to be able to clearly communicate instructions and report on progress.

Interview Tips

Preparing for an interview for an Ore Miner, Blasting position requires research, practice, and a confident mindset. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to learn about the mining company and the specific position you’re applying for. Read the job description carefully and identify key responsibilities and requirements. By demonstrating your knowledge of the company and role, you’ll show the interviewer that you’re genuinely interested and prepared.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers. Practice speaking clearly and concisely, highlighting your relevant skills and experience. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples to support your points.

3. Highlight Safety and Compliance Knowledge

Emphasize your understanding of safety procedures and environmental regulations in the mining industry. Explain how you maintain a safe work environment and comply with applicable laws and regulations. Mention any certifications or training you have that demonstrate your commitment to safety.

4. Demonstrate Teamwork and Communication Abilities

Describe your experience working effectively in a team environment and communicating with diverse individuals. Give examples of how you’ve contributed to team success and resolved conflicts or challenges.

5. Show Eagerness to Learn and Grow

Express your interest in learning new technologies and techniques related to ore mining and blasting. Highlight your willingness to take on challenges and expand your skill set. By showing a positive attitude toward continuous development, you’ll indicate your commitment to the profession and your potential for future growth.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ore Miner, Blasting role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.