Are you gearing up for an interview for a Quartz Miner, Blasting position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Quartz Miner, Blasting and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

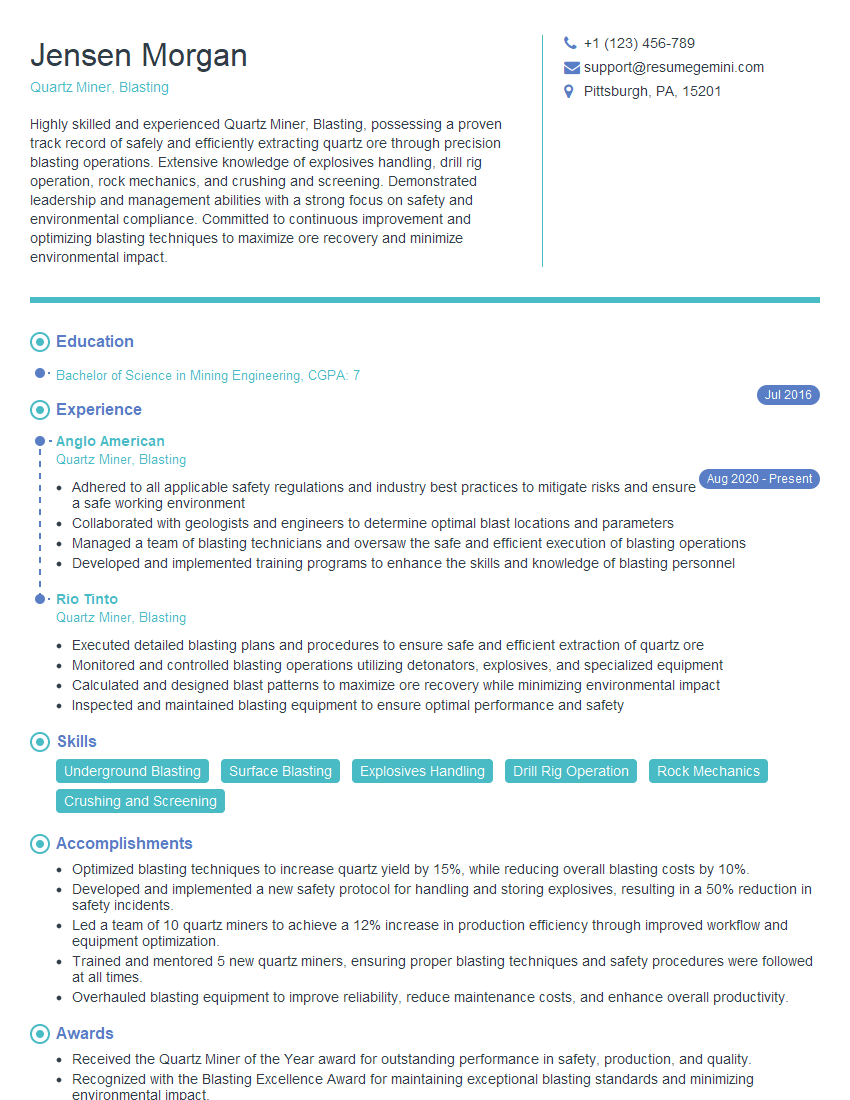

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quartz Miner, Blasting

1. Describe the process of preparing a blasting site for quartz mining.

The preparation of a blasting site for quartz mining involves several key steps:

- Site Assessment: Conduct a thorough evaluation of the site to determine the geological conditions, presence of water, and potential hazards.

- Drilling: Drill boreholes at predetermined locations and depths, according to the blasting plan.

- Charging: Load explosives (e.g., dynamite) into the boreholes, along with any necessary stemming material (e.g., sand).

- Wiring: Connect the explosives with detonating cords or blasting caps to create a firing circuit.

- Safety Measures: Implement safety protocols, including securing the site, posting warning signs, and providing protective equipment for personnel.

2. Explain the factors that influence the selection of explosives for quartz blasting.

The selection of explosives for quartz blasting depends on various factors:

Explosives Characteristics:

- Detonation velocity: Higher velocities result in stronger shock waves.

- Energy density: Determines the amount of energy released per unit mass.

- Water resistance: Important in wet or underwater conditions.

- Fume production: Excessive fumes can pose safety risks.

Site Conditions:

- Rock type: Quartz requires explosives with high detonation velocities and energy densities.

- Geology: Presence of water, faults, or other geological features may influence explosive selection.

- Environmental considerations: Some explosives may have environmental impacts that need to be considered.

3. Discuss the techniques used to achieve proper fragmentation in quartz blasting.

Achieving proper fragmentation in quartz blasting requires careful planning and execution:

- Hole Loading: Optimizing the spacing and loading of explosives to create the desired fragmentation size.

- Delay Blasting: Using multiple delays to control the timing of explosions and improve fragmentation.

- Drilling Patterns: Designing drill hole patterns to create specific fragmentation characteristics.

- Decking: Blasting in stages to control the movement and fragmentation of the rock.

4. Describe the methods used to control ground vibration during quartz blasting.

Ground vibration control is crucial in quartz blasting to minimize damage to surrounding structures:

- Charge Weight Optimization: Reducing the amount of explosives used in each blast.

- Delay Blasting: Using delays to stagger the detonation of charges and reduce peak vibrations.

- Blast Matting: Placing mats or blankets over the blast site to absorb vibrations.

- Vibration Monitoring: Using seismographs to monitor ground vibrations and adjust blasting parameters accordingly.

5. Explain the importance of proper blasting records and how they are maintained.

Blasting records provide vital information for safety, compliance, and quality control:

- Safety: Documenting blast designs, explosives used, and safety measures ensures proper handling and use of explosives.

- Compliance: Records provide evidence of compliance with regulatory requirements and industry standards.

- Quality Control: Monitoring blasting results helps optimize future blasting procedures and achieve desired fragmentation.

- Maintenance: Records assist in maintaining equipment, assessing blasting performance, and identifying areas for improvement.

Records are typically maintained in blasting logs, electronic databases, or specialized software, with regular updates and review by qualified personnel.

6. Discuss the potential environmental impacts of quartz blasting and how they can be mitigated.

Quartz blasting can have environmental impacts that need to be managed:

Air Quality:

- Dust generation: Blasting can release particulate matter and dust into the air.

- Fume production: Some explosives release toxic fumes during detonation.

Water Quality:

- Sedimentation: Blasting can create sediment runoff, affecting water quality in nearby bodies of water.

- Groundwater contamination: Explosives and blasting residues can potentially contaminate groundwater.

Noise and Vibration:

- Noise pollution: Blasting can generate loud noises that can disturb communities.

- Ground vibration: Blasting can create vibrations that can damage nearby structures and infrastructure.

Mitigation measures include:

- Dust suppression systems

- Proper explosive selection and use

- Sediment control measures

- Noise and vibration monitoring and mitigation

7. Explain the role of technology in modern quartz blasting operations.

Technology has significantly advanced quartz blasting operations:

- Computer-Aided Blasting (CAB): Software used to design blast patterns, optimize explosive charges, and predict blasting outcomes.

- Electronic Detonators: Allow for precise timing and sequencing of explosions, improving fragmentation and safety.

- Vibration Monitoring Systems: Seismographs and monitoring devices track ground vibrations and provide real-time data to adjust blasting parameters.

- GPS and Laser Surveying: Used for accurate blast site mapping, hole placement, and fragmentation analysis.

8. Describe the key safety regulations and industry standards for quartz blasting.

Safety is paramount in quartz blasting, with regulations and standards in place:

- Occupational Safety and Health Administration (OSHA): Sets regulations for explosives handling, blasting procedures, and worker safety.

- American National Standards Institute (ANSI): Publishes standards for blasting materials, techniques, and training.

- Institute of Explosives Engineers (IExE): Provides training, certification, and technical guidance on blasting practices.

- Company-Specific Policies: Mining companies often have their own safety protocols and procedures that align with industry standards.

9. Discuss the importance of ongoing training for quartz mining and blasting personnel.

Continuous training is crucial for safety and efficiency in quartz mining and blasting:

- Safety Practices: Reinforcing safe handling of explosives, blasting techniques, and emergency response protocols.

- Technological Advancements: Keeping up with the latest technology and best practices in blasting design and execution.

- Environmental Awareness: Ensuring understanding of environmental regulations and mitigation measures.

- Regulatory Compliance: Staying informed about changes in safety regulations and industry standards.

- Skill Development: Enhancing skills in blasting design, vibration control, and fragmentation analysis.

10. Share your experience in implementing innovative blasting techniques or technologies in your previous role.

In my previous role, I was involved in implementing the use of electronic detonators in quartz blasting operations:

- Improved Fragmentation: Precise timing and sequencing of explosions resulted in optimal fragmentation size and reduced waste.

- Enhanced Safety: Electronic detonators allowed for remote initiation, minimizing the risk of accidental explosions.

- Reduced Environmental Impact: By optimizing fragmentation, we were able to reduce the number of blasts required, minimizing noise and vibration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quartz Miner, Blasting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quartz Miner, Blasting‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A quartz miner, blasting, is a skilled professional responsible for extracting quartz ore from the earth using explosives. They work in hazardous environments, utilizing specialized equipment and following strict safety protocols to ensure their own safety and the safety of others.

1. Blasting Operations

Plan and execute blasting operations to extract quartz ore from the mine.

- Prepare blasting sites, including drilling boreholes, placing explosives, and connecting detonators.

- Calculate and ensure proper explosive charges and detonation sequences.

2. Equipment Operation

Operate heavy machinery, including drills, excavators, and loaders, to facilitate ore extraction.

- Maintain and repair machinery to ensure optimal performance and safety.

- Troubleshoot and resolve equipment malfunctions to minimize downtime.

3. Ore Processing

Assist in ore processing operations, such as crushing, screening, and sorting, to prepare quartz ore for further use.

- Monitor ore quality and ensure it meets specifications.

- Operate and maintain processing equipment to maximize efficiency and minimize downtime.

4. Safety and Compliance

Adhere to strict safety regulations and industry best practices.

- Wear appropriate personal protective equipment (PPE) and follow safety protocols to minimize risk.

- Monitor environmental conditions and take measures to mitigate potential hazards.

Interview Tips

Preparing for an interview can be nerve-wracking, but with the right approach, you can increase your chances of success. Here are some tips to help you ace your interview for a quartz miner, blasting position:

1. Research the Company and Role

Take the time to thoroughly research the mining company and the specific role you’re applying for. This will demonstrate your interest in the position and the company’s values.

- Visit the company’s website and social media pages.

- Read industry news and articles about the company’s operations.

2. Highlight Relevant Skills and Experience

In your resume and interview, emphasize your skills and experience that are directly relevant to the job. For example, discuss your knowledge of explosives handling, heavy machinery operation, and safety regulations.

- Quantify your accomplishments using specific metrics and data whenever possible.

- Prepare examples of situations where you successfully applied your skills in a practical setting.

3. Be Enthusiastic and Professional

Employers are looking for candidates who are passionate about their work and have a strong work ethic. Show your enthusiasm for the mining industry and the role by being engaged and asking thoughtful questions during the interview.

- Dress professionally and arrive on time for your interview.

- Maintain eye contact and actively listen to the interviewer’s questions.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to blasting operations, equipment operation, and safety protocols. These questions may be specific to the mining company’s methods and procedures.

- Review blasting techniques, explosive types, and safety regulations.

- Familiarize yourself with the different types of heavy machinery used in mining operations.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Quartz Miner, Blasting role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.