Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Crusher Loader Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Crusher Loader Operator so you can tailor your answers to impress potential employers.

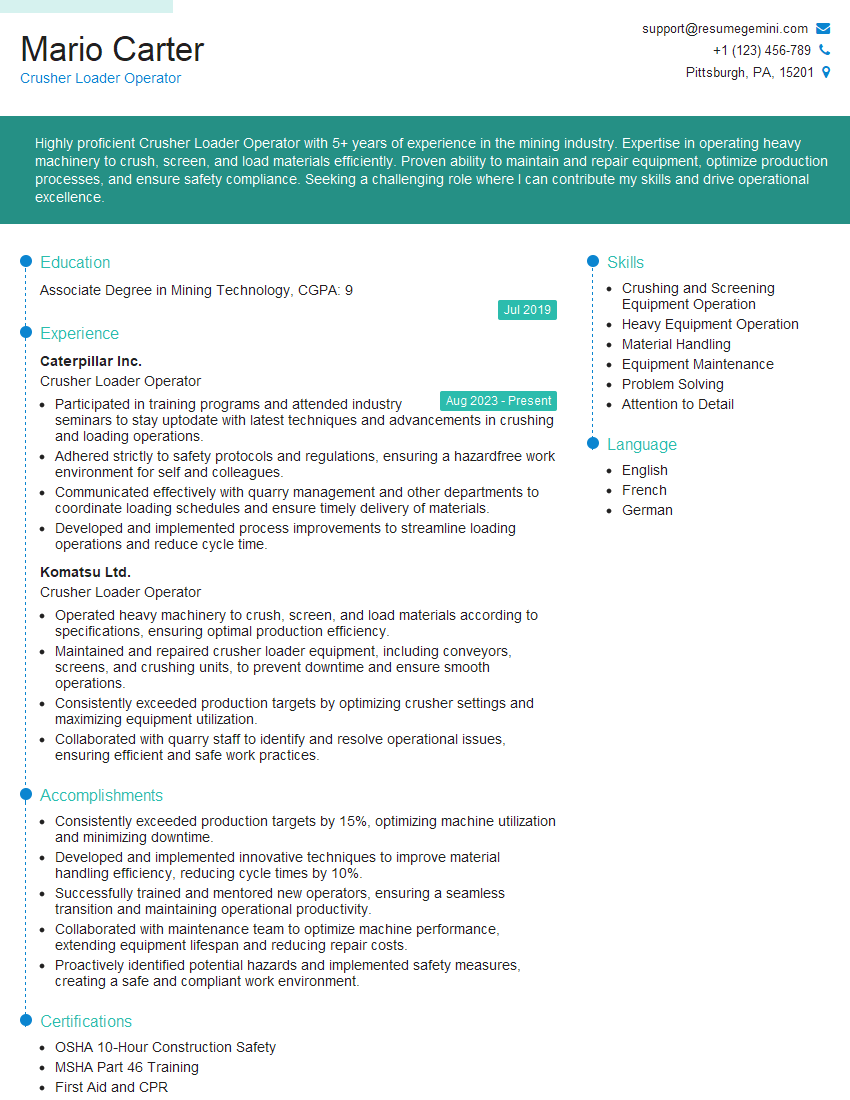

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crusher Loader Operator

1. Describe the process of maintaining a Crusher Loader and how often it should be done?

Maintaining a Crusher Loader involves regular inspections, servicing, and repairs to ensure optimal performance and prevent breakdowns.

- Daily Inspections: Visual checks of belts, bearings, hydraulics, and lubrication levels.

- Weekly Servicing: Lubrication of moving parts, cleaning of screens and conveyors, and checking of tire pressure.

- Monthly Maintenance: More thorough inspections, including belt tensioning, bearing checks, and hydraulic fluid changes.

- Quarterly Overhauls: Comprehensive inspections and repairs, including replacement of worn parts and calibration of sensors.

2. What are the safety precautions that must be taken when operating a Crusher Loader?

Personal Protective Equipment

- Wear hard hat, safety glasses, earplugs, and high-visibility clothing.

Crusher Area

- Stay clear of moving parts and follow designated walkways.

- Securely fasten all gates and guards before operating.

Material Handling

- Inspect materials for foreign objects before loading.

- Do not overload the crusher or feed excessive material.

Emergencies

- Know the location of emergency stop buttons and evacuation routes.

- Stay calm and follow established procedures in case of incidents.

3. How do you troubleshoot a Crusher Loader that is not feeding material properly?

Troubleshooting a Crusher Loader that is not feeding material properly involves a systematic approach to identify and rectify the issue.

- Check Material Supply: Ensure there is sufficient material available and that conveyors are operating correctly.

- Inspect Feed Apron: Examine the feed apron for any damage or obstructions that may be preventing material from entering the crusher.

- Inspect Jaw Plates: Check the jaw plates for wear or misalignment, which can affect material flow.

- Check Hydraulic Pressure: Verify if hydraulic pressure is sufficient to operate the feed mechanism.

- Reset Sensors: If sensors are malfunctioning, they may inhibit the feeding process. Try resetting or replacing them.

4. What are the critical components of a Crusher Loader and their functions?

- Feeder: Controls the flow of material into the crusher.

- Crusher Head: Breaks down larger rocks into smaller sizes.

- Conveyor Belt: Transports material away from the crusher.

- Hydraulic System: Provides power for the feeder, crusher, and other components.

- Electrical System: Powers the control panel and safety features.

5. How do you adjust the settings of a Crusher Loader to achieve different product sizes?

Adjusting the settings of a Crusher Loader is crucial to control the size of the crushed material.

- Jaw Gap: Adjusting the gap between the jaw plates affects the size of particles produced.

- Conveyor Speed: Varying the speed of the conveyor can control the residence time of material in the crusher.

- Feeder Rate: Regulating the rate at which material is fed into the crusher impacts product size.

6. Explain the importance of calibrating the load cells on a Crusher Loader and how it is done?

Calibrating the load cells on a Crusher Loader ensures accurate weighing of the processed material, which is essential for production accounting and quality control.

- Use Certified Test Weights: Place known weights on the conveyor belt and adjust the load cell readings to match.

- Perform Multiple Calibrations: Conduct calibrations at different load ranges to ensure accuracy across the entire operating range.

- Regular Recalibration: Schedule regular recalibrations to maintain accuracy and compensate for any wear or drift in the load cells.

7. Describe the preventative maintenance procedures you would implement to minimize breakdowns of a Crusher Loader?

- Regular Inspections: Conduct daily and weekly inspections to identify potential issues early on.

- Lubrication: Follow a lubrication schedule to ensure all moving parts are adequately greased.

- Belt Maintenance: Inspect and tighten belts regularly to prevent slippage and extend their lifespan.

- Hydraulic System Maintenance: Change hydraulic fluids and filters according to the manufacturer’s recommendations.

- Component Replacement: Replace worn or damaged components promptly to prevent further breakdowns.

8. How do you handle unexpected equipment failures and ensure minimal downtime?

Unexpected equipment failures can occur, and it is crucial to respond promptly and effectively to minimize downtime.

- Isolate the Failure: Identify the source of the failure and isolate it from the rest of the system.

- Assess Damage: Determine the extent of the damage and whether it can be repaired on-site or requires external assistance.

- Initiate Repairs: Contact maintenance personnel or suppliers to initiate repairs as soon as possible.

- Plan for Contingency: If repairs cannot be made immediately, implement contingency measures to maintain production, such as using backup equipment or rescheduling operations.

9. How do you optimize the performance of a Crusher Loader to achieve maximum efficiency and productivity?

- Regular Maintenance: Implement a comprehensive maintenance schedule to prevent breakdowns and ensure optimal performance.

- Fine-Tune Settings: Adjust crusher settings to achieve the desired product size and minimize waste.

- Monitor Performance: Track production rates, downtime, and energy consumption to identify areas for improvement.

- Train Operators: Provide training to operators to enhance their skills and knowledge of the equipment.

10. Describe any innovative solutions or technologies you have implemented to improve the operation of Crusher Loaders?

- Remote Monitoring System: Implemented a remote monitoring system to track equipment performance, identify potential issues, and schedule maintenance proactively.

- Automated Feed Control: Integrated an automated feed control system to optimize material flow and prevent overloading.

- Energy-Efficient Motors: Replaced conventional motors with energy-efficient models to reduce power consumption and operating costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crusher Loader Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crusher Loader Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Crusher Loader Operators play a crucial role in the production process by maneuvering heavy machinery to feed material into crushing and screening equipment. Key responsibilities include:

1. Material Handling

Operate loaders to collect and transport material to the crusher or conveyor systems. Ensure proper material flow and prevent equipment damage.

2. Equipment Operation

Control and maintain loaders, including track, wheel, and skid steer models. Monitor equipment performance and identify any issues requiring maintenance.

3. Safety Compliance

Adhere to all safety regulations and protocols related to equipment operation and material handling. Use protective gear and follow established safety procedures.

4. Production Monitoring

Collaborate with other operators to monitor production levels and ensure efficient material flow. Identify bottlenecks and suggest improvements to enhance productivity.

5. Maintenance and Troubleshooting

Perform basic equipment maintenance and troubleshooting. Conduct routine inspections and promptly report any issues to supervisors or maintenance personnel.

Interview Tips

To ace the interview for a Crusher Loader Operator position, follow these tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the crushing industry by researching their operations, products, and safety record. Showcase your understanding of the role and how your skills align with their needs.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Prepare for Technical Questions

Expect questions related to loader operation, safety procedures, and troubleshooting techniques. Review your knowledge of equipment mechanics, material handling, and safety protocols. Practice answering questions clearly and concisely.

- Review your experience handling different types of loaders.

- Describe specific safety measures you follow in your work.

3. Highlight Relevant Experience

Emphasize your experience in material handling, equipment operation, and maintenance. Provide specific examples of your contributions to previous projects and how they apply to the role. Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Describe a time when you effectively handled a large volume of material under pressure.

- Share an experience where you identified and resolved an equipment malfunction.

4. Demonstrate Safety Consciousness

Safety is paramount in this role. Emphasize your commitment to following safety protocols and your role in maintaining a safe work environment. Highlight any safety certifications or training you possess.

- Explain your understanding of the safety protocols for the equipment you operate.

- Describe a situation where you prioritized safety over productivity.

5. Be Professional and Enthusiastic

Present yourself professionally and demonstrate enthusiasm for the role. Ask thoughtful questions about the company, the position, and the industry. Your positive attitude and eagerness to learn will make a lasting impression.

- Dress appropriately and arrive on time for the interview.

- Be prepared to answer questions about your availability and career goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Crusher Loader Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!