Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mine Cutting and Channeling Machine Copper Miner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

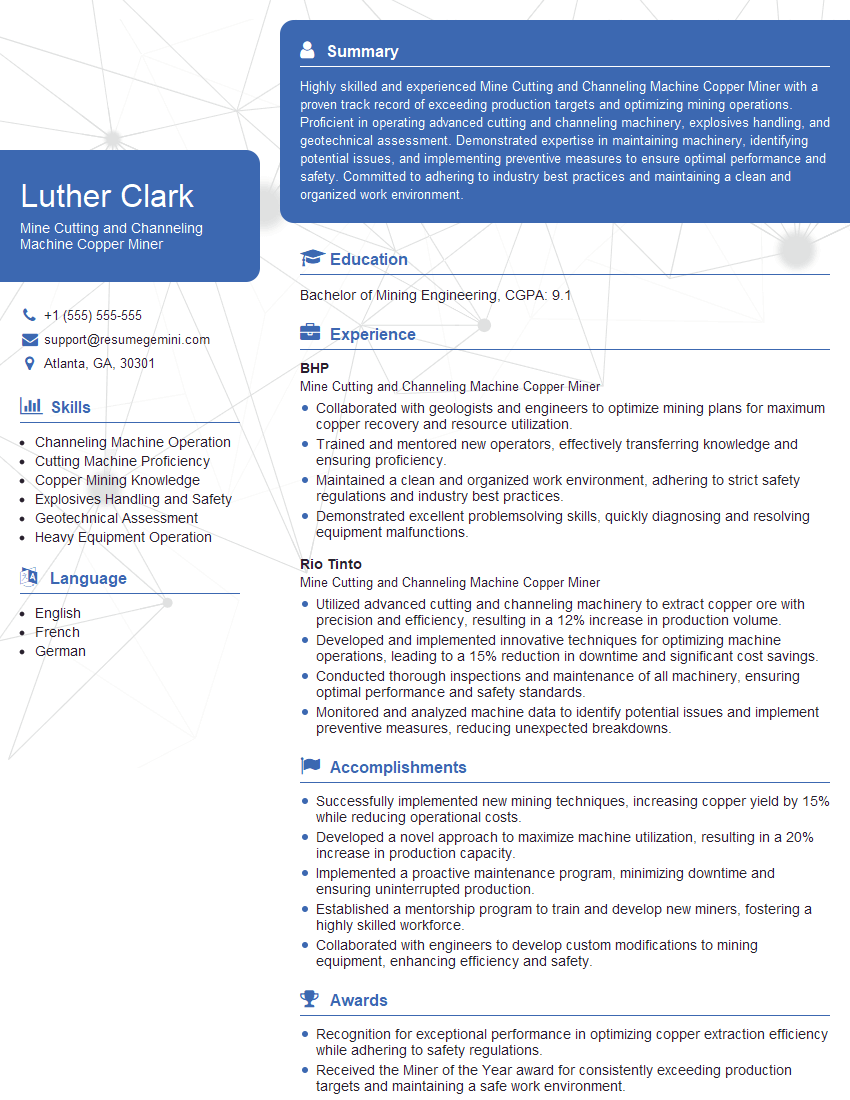

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mine Cutting and Channeling Machine Copper Miner

1. What are the key safety precautions that you must take while operating a mine cutting and channeling machine?

To ensure safety while operating a mine cutting and channeling machine, I strictly adhere to the following precautions:

- Thoroughly inspect the machine before each use, checking for any damage or loose connections.

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, earplugs, and gloves.

- Ensure the work area is well-ventilated to prevent the accumulation of harmful dust or gases.

- Maintain a safe distance from other workers and equipment to avoid accidents.

- Never operate the machine while under the influence of drugs or alcohol.

- Follow established operating procedures and never attempt any unauthorized modifications to the machine.

2. Explain the different types of cutting heads used in mine cutting and channeling machines and their specific applications.

Diamond-tipped cutting heads

- Used for cutting hard rock formations such as granite and quartzite.

- Provide clean and precise cuts with minimal chipping or fracturing.

Tungsten carbide-tipped cutting heads

- Suitable for cutting softer rock formations such as sandstone and limestone.

- Offer a good balance between durability and cutting efficiency.

Drag bits

- Used for trenching and channeling operations where high cutting rates are required.

- Designed to break and pulverize the rock rather than cut it.

3. Describe the maintenance procedures you perform on a mine cutting and channeling machine to ensure its optimal performance and safety.

To maintain optimal performance and safety of the mine cutting and channeling machine, I perform the following maintenance procedures:

- Regularly clean and lubricate all moving parts, including the cutting head, drive system, and bearings.

- Inspect and replace worn or damaged components, such as cutting teeth, drive belts, and hydraulic hoses.

- Check and adjust the tension of the cutting chain to ensure proper cutting efficiency.

- Monitor hydraulic fluid levels and replace or top up as necessary.

- Perform regular electrical inspections to ensure proper functioning of all electrical components.

4. How do you determine the appropriate cutting depth and feed rate for a given rock formation and cutting application?

To determine the appropriate cutting depth and feed rate, I consider the following factors:

- Rock hardness and abrasiveness

- Desired depth of cut

- Type of cutting head used

- Machine capabilities

I typically start with a conservative depth of cut and feed rate, and gradually adjust them based on the performance of the machine and the quality of the cut.

5. What are the common troubleshooting techniques you use to resolve issues with a mine cutting and channeling machine?

When troubleshooting issues with a mine cutting and channeling machine, I follow these steps:

- Identify the problem and observe the symptoms carefully.

- Refer to the manufacturer’s manual for possible causes and solutions.

- Inspect the machine thoroughly, checking for loose connections, damaged components, or hydraulic leaks.

- Perform basic electrical tests to ensure proper continuity and voltage.

- Consult with experienced colleagues or the manufacturer’s support team for assistance if needed.

6. Explain the importance of proper dust control measures when operating a mine cutting and channeling machine.

Proper dust control measures are crucial when operating a mine cutting and channeling machine for the following reasons:

- Health hazards: Inhalation of excessive dust can lead to respiratory problems, such as silicosis and lung cancer.

- Visibility reduction: Dust can obstruct visibility, increasing the risk of accidents.

- Equipment damage: Dust can accumulate on machine components, causing premature wear and tear.

7. Describe the different methods used to control dust generated by a mine cutting and channeling machine.

- Wet cutting: Using water or coolant to suppress dust during cutting.

- Dust collection systems: Vacuum cleaners or dust collectors to capture and remove dust from the work environment.

- Ventilation: Proper ventilation to dilute and remove dust from the air.

- Personal protective equipment (PPE): Respirators or dust masks to protect workers from inhaling dust.

8. What are the key performance indicators (KPIs) used to measure the effectiveness of a mine cutting and channeling operation?

- Cutting rate: The speed at which the machine can cut through rock.

- Depth of cut: The maximum depth that the machine can cut in a single pass.

- Accuracy: The precision with which the machine can follow a prescribed cutting path.

- Equipment utilization: The percentage of time that the machine is actively cutting rock.

- Maintenance downtime: The amount of time spent on maintenance and repairs.

9. Explain how you would optimize the cutting efficiency of a mine cutting and channeling machine.

To optimize cutting efficiency, I consider the following factors:

- Matching machine to rock formation: Selecting the appropriate machine and cutting head for the specific rock type.

- Optimizing cutting parameters: Determining the ideal cutting depth, feed rate, and water flow rate.

- Regular maintenance: Ensuring the machine is properly maintained and all components are in good working condition.

- Minimizing downtime: Planning maintenance and repairs to avoid interruptions during critical cutting operations.

- Operator training: Providing operators with proper training to maximize their skills and knowledge.

10. Describe the challenges you have faced while operating a mine cutting and channeling machine and how you overcame them.

One challenging situation I encountered was operating the machine in a narrow and confined space. The limited room made it difficult to maneuver the machine and maintain a safe distance from the rock face.

To overcome this challenge, I carefully planned the cutting sequence, taking into account the space constraints. I used a smaller cutting head and adjusted the cutting parameters to minimize the risk of accidents.

Additionally, I worked closely with a spotter to ensure that the machine was operating safely and that everyone in the vicinity was aware of its movements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mine Cutting and Channeling Machine Copper Miner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mine Cutting and Channeling Machine Copper Miner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mine Cutting and Channeling Machine Copper Miners operate and maintain specialized machinery to cut and channel rock in underground copper mines.

1. Operate Cutting and Channeling Machines

Use cutting and channeling machines to cut and shape rock surfaces in underground mines.

- Set up and position machines at designated locations according to mining plans.

- Control and operate machines to cut slots or channels into rock, creating a precise path for future mining activities.

2. Maintain and Repair Equipment

Perform routine maintenance and repairs on cutting and channeling machines, ensuring optimal functionality and safety.

- Inspect machines for any damage or wear and tear, and make necessary adjustments or repairs.

- Replace worn or damaged parts, such as cutting blades, chains, or lubricants.

3. Monitor Work Area

Continuously monitor the cutting and channeling operations, ensuring efficient and safe work conditions.

- Observe the rock formation and adjust machine settings or operating parameters as needed.

- Identify and address any potential hazards or safety concerns in the work area.

- Communicate with other miners to coordinate activities and ensure smooth operations.

4. Adhere to Safety Protocols

Strictly adhere to established safety protocols and regulations to minimize risks and ensure a safe work environment.

- Wear appropriate personal protective equipment (PPE) and follow established safety procedures.

- Inspect equipment regularly and report any defects or issues to supervisors promptly.

- Maintain a clean and organized work area, free from hazards or obstructions.

Interview Tips

Preparing for an interview can help you showcase your skills and increase your chances of success. Here are some tips to help you ace your interview for a Mine Cutting and Channeling Machine Copper Miner position:

1. Research the Company and Industry

Familiarize yourself with the mining company, its operations, and the specific requirements of the role. This will demonstrate your interest in the position and your commitment to the industry.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and knowledge of the mining industry. Practice answering questions clearly and concisely, emphasizing your relevant qualifications.

3. Highlight Your Technical Expertise

Emphasize your proficiency in operating and maintaining mining equipment, especially cutting and channeling machines. Provide specific examples of your experience and demonstrate your ability to troubleshoot and resolve technical issues.

4. Showcase Your Safety Consciousness

Mining is a safety-critical industry. Highlight your strong commitment to safety and your understanding of safety protocols and regulations. Describe your experience in adhering to safety procedures and maintaining a safe work environment.

5. Prepare Questions for the Interviewer

Prepare thoughtful questions to ask the interviewer. This shows your engagement in the interview process and your interest in the company and the role. Questions about safety practices, environmental stewardship, and career advancement opportunities are appropriate.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for your interview and arrive punctually. This demonstrates your respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mine Cutting and Channeling Machine Copper Miner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!