Feeling lost in a sea of interview questions? Landed that dream interview for Optical Manufacturing Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Optical Manufacturing Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

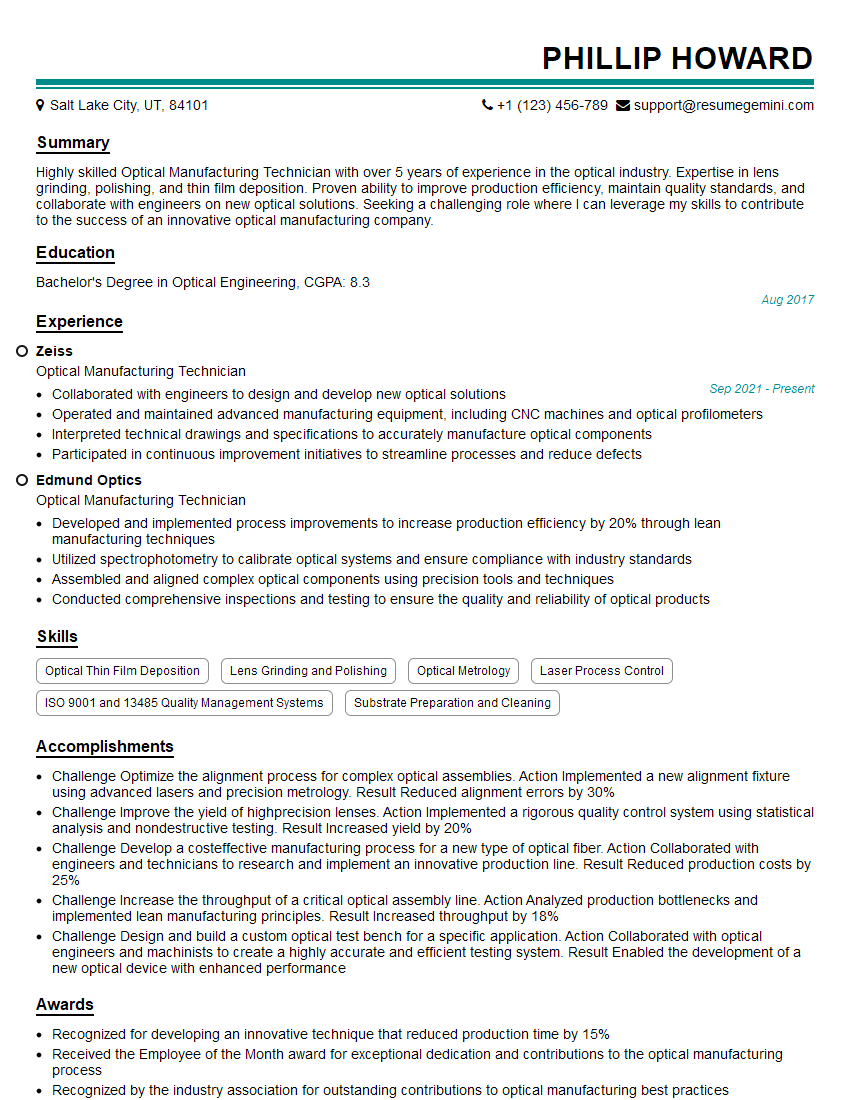

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Optical Manufacturing Technician

1. Describe the process of optical grinding and polishing.

Optical grinding and polishing is a crucial process in the manufacturing of optical components, such as lenses and mirrors. It involves removing material from a substrate to achieve precise surface shape and finish. Here’s an overview of the process:

- Grinding: This stage involves removing large amounts of material using abrasive wheels or stones. It shapes the surface of the substrate and prepares it for further processing.

- Polishing: Polishing is performed to achieve a smooth and precise surface finish. It removes fine defects and imperfections, utilizing abrasive powders and pads to gradually refine the surface.

- Fine Polishing: For high-precision applications, fine polishing may be employed to achieve extremely smooth surfaces. It utilizes finer abrasive powders and specialized pads to minimize surface roughness and improve optical performance.

2. Explain the principles of optical alignment and its importance in optical manufacturing.

Accuracy and Precision

- Optical alignment ensures that optical components are positioned and oriented correctly relative to each other. This is critical for achieving the desired optical performance, such as image quality and system efficiency.

Minimizing Errors

- Proper alignment minimizes errors that can arise from misalignments, such as aberrations, distortions, and reduced light throughput. By precisely aligning components, the system can function optimally and deliver accurate results.

3. Describe the different types of optical materials used in manufacturing and their properties.

In optical manufacturing, various types of materials are used, each possessing unique properties that make them suitable for specific applications. Here are some common types:

- Glass: Glass is a versatile material offering high optical clarity, low thermal expansion, and good mechanical strength. It’s commonly used for lenses, prisms, and windows.

- Crystals: Crystals possess excellent optical properties, such as high refractive indices and birefringence. They are often used in laser optics, nonlinear optics, and polarizing elements.

- Polymers: Polymers are lightweight, durable, and relatively inexpensive. They are used in applications where weight and cost constraints are critical, such as in plastic lenses and optical fibers.

- Metals: Metals, like aluminum and stainless steel, are employed in optical systems for structural support, reflective surfaces, and thermal management.

4. Discuss the role of metrology in optical manufacturing.

Metrology plays a vital role in optical manufacturing by providing precise measurements and characterization of optical components. It ensures that the components meet the required specifications and perform as intended. Some key aspects of metrology in optical manufacturing include:

- Dimensional Measurements: Metrology tools measure the physical dimensions of optical components, such as diameter, thickness, and surface profile, to ensure they meet design specifications.

- Optical Testing: Optical testing assesses the optical performance of components, including their transmission, reflection, and diffraction properties. This ensures they meet the required optical quality standards.

- Surface Characterization: Metrology techniques characterize the surface roughness, defects, and other surface properties of optical components. This information is crucial for optimizing optical performance and minimizing scattering losses.

5. Explain the importance of cleanliness and contamination control in optical manufacturing.

Cleanliness and contamination control are paramount in optical manufacturing to prevent defects and ensure the integrity of optical components. Contamination, such as dust particles or fingerprints, can disrupt the optical path, scatter light, and degrade system performance. Therefore, strict measures are taken to maintain a clean environment and minimize contamination:

- Cleanroom Facilities: Optical manufacturing is often performed in cleanroom environments that control the levels of dust, particles, and other contaminants in the air.

- Specialized Equipment: Specialized equipment, such as laminar flow hoods and anti-static tools, is used to minimize contamination during handling and assembly.

- Regular Cleaning and Inspection: Regular cleaning and inspection procedures are implemented to remove contaminants and monitor the cleanliness of work areas and equipment.

6. Describe the process of assembling and aligning optical systems.

Assembling and aligning optical systems requires precision and expertise to ensure proper functionality and performance. Here’s an overview of the process:

- Component Preparation: Optical components are carefully cleaned and inspected before assembly to ensure they are free of contamination and defects.

- Alignment and Mounting: Components are aligned and mounted in the system using specialized tools and techniques to achieve precise positioning and orientation.

- Optical Alignment: Advanced optical alignment techniques, such as interferometry and autocollimation, are employed to fine-tune the alignment of components and optimize system performance.

7. Discuss the quality control procedures used in optical manufacturing.

Quality control procedures are crucial in optical manufacturing to ensure that products meet the required specifications and standards. These procedures involve rigorous testing and inspection at various stages of the manufacturing process:

- Incoming Material Inspection: Raw materials and components are inspected upon receipt to verify their quality and conformance to specifications.

- In-Process Inspections: Inspections are performed throughout the manufacturing process to monitor progress, identify potential defects, and ensure adherence to quality standards.

- Final Inspection and Testing: Completed optical components and systems undergo thorough inspections and testing to assess their optical performance, dimensions, and compliance with customer requirements.

8. Describe the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) in optical manufacturing.

CAD and CAM play a significant role in optical manufacturing by streamlining the design and production processes. Here’s how they are utilized:

CAD (Computer-Aided Design)

- Design and Modeling: CAD software allows engineers to design and model optical components and systems with precision and accuracy.

- Simulation and Analysis: CAD models can be used for optical simulations and analyses to optimize designs and predict system performance.

CAM (Computer-Aided Manufacturing)

- CNC Machining: CAM software generates toolpaths for CNC machines that precisely shape and grind optical components based on the CAD design.

- Automated Assembly: CAM systems can control automated assembly processes, ensuring accurate alignment and positioning of optical components.

9. Explain the concept of optical tolerancing and its importance in optical manufacturing.

Optical tolerancing is a crucial aspect of optical manufacturing that involves defining and controlling the allowable variations in optical components and systems. It ensures that the final product meets the desired performance specifications while minimizing manufacturing costs and maximizing yield.

- Impact on Performance: Optical tolerancing considers the impact of manufacturing variations on optical performance parameters, such as image quality, diffraction, and aberrations.

- Cost Optimization: By optimizing tolerances, manufacturers can reduce the cost of production while maintaining the required optical performance.

10. Describe the importance of understanding the principles of optics and optical design for an optical manufacturing technician.

For an optical manufacturing technician, understanding the principles of optics and optical design is essential for:

- Process Optimization: Knowledge of optics helps technicians understand the impact of manufacturing processes on optical performance and optimize production techniques accordingly.

- Troubleshooting: A deep understanding of optical principles enables technicians to effectively troubleshoot and resolve any issues that may arise during manufacturing.

- Quality Control: By comprehending optical design, technicians can perform more accurate quality control checks and ensure the production of high-quality optical components.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Optical Manufacturing Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Optical Manufacturing Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Optical Manufacturing Technicians play a key role in the manufacturing of optical components and systems. They are responsible for a variety of tasks, including:

1. Fabricating Optical Components

Optical Manufacturing Technicians fabricate optical components using a variety of techniques, including grinding, polishing, and coating. They must have a strong understanding of optics and be able to work with precision equipment.

- Grind and polish optical surfaces to precise specifications.

- Coat optical surfaces with thin films to improve their performance.

2. Assembling Optical Systems

Optical Manufacturing Technicians also assemble optical systems, such as telescopes, microscopes, and lasers. They must be able to work with a variety of materials and be able to follow complex assembly instructions.

- Assemble optical components into complex systems.

- Align and adjust optical systems to ensure proper performance.

3. Testing Optical Components and Systems

Optical Manufacturing Technicians test optical components and systems to ensure that they meet specifications. They use a variety of test equipment, including interferometers, spectrophotometers, and lasers.

- Test optical components and systems to ensure that they meet specifications.

- Troubleshoot and repair optical components and systems.

4. Maintaining Optical Equipment

Optical Manufacturing Technicians also maintain optical equipment. They clean, repair, and calibrate equipment to ensure that it is operating properly.

- Clean, repair, and calibrate optical equipment.

- Maintain a safe and clean work environment.

Interview Tips

Preparing for an interview can be a daunting task, but it is important to remember that the interviewer is just as interested in finding the right candidate as you are in finding in finding the right job. By following these tips, you can increase your chances of making a good impression and landing the job you want.

1. Research the Company

Before you go to your interview, take some time to research the company. This will help you understand the company’s culture, values, and goals. You can find information about the company on its website, social media pages, and Glassdoor.

- Visit the company’s website and social media pages.

- Read articles about the company in the news.

- Talk to people who work at the company.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Write down your answers to common interview questions.

- Practice answering the questions out loud.

- Get feedback from a friend or family member.

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of an interview shows that you are interested in the job and the company. It also gives you an opportunity to learn more about the position and the company culture. Some good questions to ask include: “What are the biggest challenges facing the company right now?” and “What is the company’s culture like?”

- Write down a list of questions to ask the interviewer.

- Practice asking the questions out loud.

- Be prepared to answer questions about your own questions.

4. Dress Professionally

Dressing professionally for an interview shows that you respect the interviewer and the company. It also makes you look more confident and polished. When choosing what to wear, opt for clothing that is clean, pressed, and fits well. You should also avoid wearing clothing that is too revealing or casual.

- Wear a suit or dress pants and a button-down shirt or blouse.

- Make sure your clothes are clean, pressed, and fit well.

- Avoid wearing clothing that is too revealing or casual.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic, and let your personality shine through.

- Be honest and authentic.

- Let your personality shine through.

- Don’t try to be someone you’re not.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Optical Manufacturing Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.