Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sandstone Splitter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

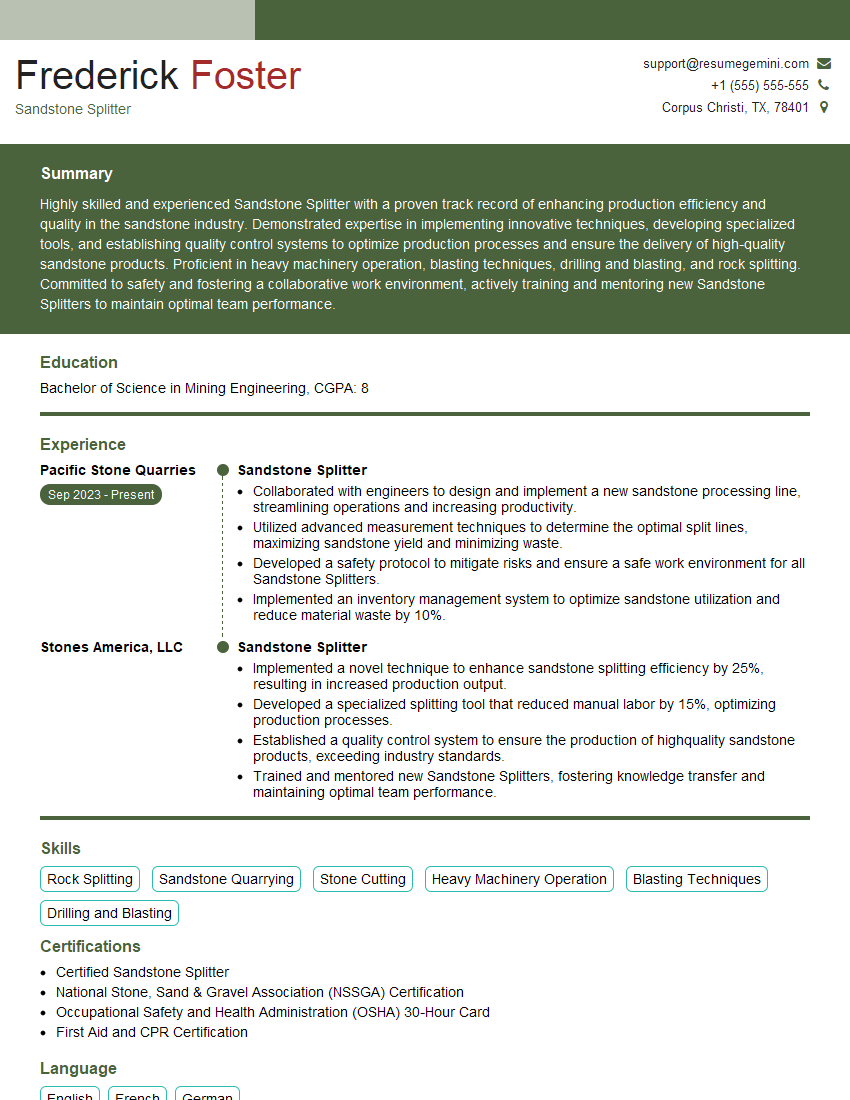

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sandstone Splitter

1. What tools and equipment are you experienced in using for sandstone splitting?

- Hand tools such as chisels, mallets, and wedges

- Power tools such as jackhammers, pneumatic splitters, and diamond saws

- Specialized equipment such as sandstone saws and guillotines

2. How do you determine the natural cleavage planes of sandstone?

Visual Observation:

- Inspect the sandstone surface for visible cracks, joints, and bedding planes.

- Look for changes in color, texture, or grain size that indicate potential cleavage planes.

Sounding:

- Tap the sandstone with a hammer or chisel.

- Listen for a clear, ringing sound that indicates a solid, uniform material.

- Identify areas that produce a dull or hollow sound, which may indicate cleavage planes.

3. What are the safety precautions you observe when splitting sandstone?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Establish a safe work area away from hazards and bystanders.

- Inspect tools and equipment regularly to ensure they are in good working order.

- Use proper techniques and follow established safety protocols.

- Be aware of potential hazards such as flying debris, sharp edges, and heavy equipment.

4. How do you assess the quality of sandstone for splitting?

- Examine the sandstone for cracks, fissures, or other defects that may affect its strength and integrity.

- Inspect the grain size and texture to determine its hardness and uniformity.

- Consider the presence of minerals or impurities that may affect the quality of the split.

- Conduct tests, such as compressive strength tests, to evaluate its structural properties.

5. What techniques do you use to split sandstone along irregular lines and shapes?

- Use a diamond saw to make precise cuts along the desired line.

- Employ a pneumatic chisel or jackhammer with a specialized bit to create controlled fractures.

- Utilize a guillotine or hydraulic splitter for larger blocks, providing a clean and efficient split.

- Apply a combination of techniques to achieve complex shapes and patterns.

6. Explain the difference between natural and manufactured sandstone splitters.

- Natural Splitters:

- Derived from naturally occurring sandstone formations with existing cleavage planes.

- Require less processing and are often more cost-effective.

- Manufactured Splitters:

- Created using specialized machinery and techniques to achieve desired shapes and sizes.

- Offer greater precision and consistency in splitting.

7. What are the different types of sandstone sealers and their applications?

- Penetrating Sealers: Penetrate the sandstone pores, repelling water and stains.

- Film-Forming Sealers: Create a protective layer on the sandstone surface, preventing moisture absorption.

- Combination Sealers: Provide both penetrating and film-forming properties.

- Water Repellents: Repel water but allow vapor to escape, preventing moisture buildup.

- Color Enhancers: Enhance the natural colors and patterns of the sandstone while providing protection.

8. How do you determine the appropriate size and spacing of wedges for splitting sandstone?

- Consider the thickness and hardness of the sandstone.

- Use wedges that are slightly wider than the natural cleavage planes.

- Space the wedges evenly along the intended split line.

- Adjust the spacing based on the desired split size and shape.

9. Describe the process of restoring and repairing damaged sandstone.

- Clean the damaged area to remove dirt, debris, and loose fragments.

- Repair cracks and fissures using specialized epoxy or mortar.

- Replace missing or severely damaged pieces with compatible sandstone.

- Seal and protect the repaired area to prevent further damage.

10. What are the challenges and solutions in splitting large sandstone blocks?

- Challenges:

- Weight and handling difficulties.

- Risk of fractures and breakages.

- Specialized equipment and techniques required.

- Solutions:

- Use lifting equipment and cranes to handle heavy blocks.

- Employ controlled splitting techniques, such as line drilling or wire sawing.

- Utilize hydraulic splitters or guillotines for efficient and precise cuts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sandstone Splitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sandstone Splitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sandstone Splitters are responsible for extracting sandstone from quarries and preparing it for use in construction and other industries. Their duties encompass various aspects of sandstone processing, ensuring that the extracted sandstone meets the required specifications.

1. Sandstone Extraction

Splitters begin by identifying and accessing sandstone deposits within quarries. Using specialized tools and equipment, they extract sandstone blocks or slabs from the quarry face.

- Operate heavy machinery, such as drills, saws, and excavators

- Determine the optimal extraction methods based on rock formations and safety protocols

2. Block Preparation

Once extracted, sandstone blocks undergo preparation to remove impurities and prepare them for further processing. Splitters employ various techniques to enhance the quality of the sandstone.

- Trim excess rock and remove imperfections to ensure uniformity

- Wash and clean sandstone blocks to eliminate dirt and debris

3. Splitting and Cutting

Sandstone Splitters employ specialized techniques to split sandstone blocks into smaller, usable pieces. They use wedges, chisels, or mechanical splitters to separate the sandstone along its natural lines of weakness, creating slabs or tiles of the desired dimensions.

- Utilize specialized tools to split sandstone along its natural grain

- Cut sandstone into specific shapes and sizes using saws or other cutting equipment

4. Finishing and Packaging

After splitting and cutting, Splitters perform finishing touches on the sandstone products. This includes shaping, smoothing, and polishing the surfaces to meet the required specifications. They also prepare the sandstone for packaging and transportation to ensure it reaches the end-user in optimal condition.

- Shape and smooth sandstone surfaces using hand tools or machinery

- Package and prepare sandstone products for shipping and delivery

Interview Tips

Preparing for a Sandstone Splitter interview requires a combination of technical knowledge, industry awareness, and effective communication skills. Here are some tips to help you ace the interview and showcase your qualifications.

1. Research the Company and Role

Before the interview, thoroughly research the company’s history, operations, and the specific role of a Sandstone Splitter within their organization. This demonstrates your interest and prepares you to ask insightful questions.

- Visit the company’s website to learn about their products, services, and industry standing.

- Read industry publications and articles to stay updated on trends and best practices in sandstone processing.

2. Highlight Your Technical Skills

Sandstone Splitters are expected to possess a strong understanding of sandstone properties, extraction techniques, and processing equipment. Emphasize your knowledge and experience in these areas during the interview.

- Describe your proficiency in operating heavy machinery, such as drills, saws, and excavators.

- Explain your understanding of sandstone geology and how it influences extraction and splitting methods.

3. Showcase Your Safety Awareness

Quarrying and sandstone processing involve potential hazards. Demonstrate your commitment to safety by highlighting your knowledge of industry regulations and your experience in implementing safe work practices.

- Discuss your understanding of OSHA or other relevant safety regulations.

- Describe your experience in using personal protective equipment (PPE) and implementing safety protocols.

4. Emphasize Your Communication and Teamwork Skills

Sandstone Splitters often work as part of a team and interact with clients. Highlight your ability to communicate effectively, collaborate with others, and build strong relationships.

- Describe your experience working in a team environment and contributing to successful outcomes.

- Explain how you maintain open communication and resolve conflicts professionally.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sandstone Splitter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!