Feeling lost in a sea of interview questions? Landed that dream interview for Well Service Floorperson but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Well Service Floorperson interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

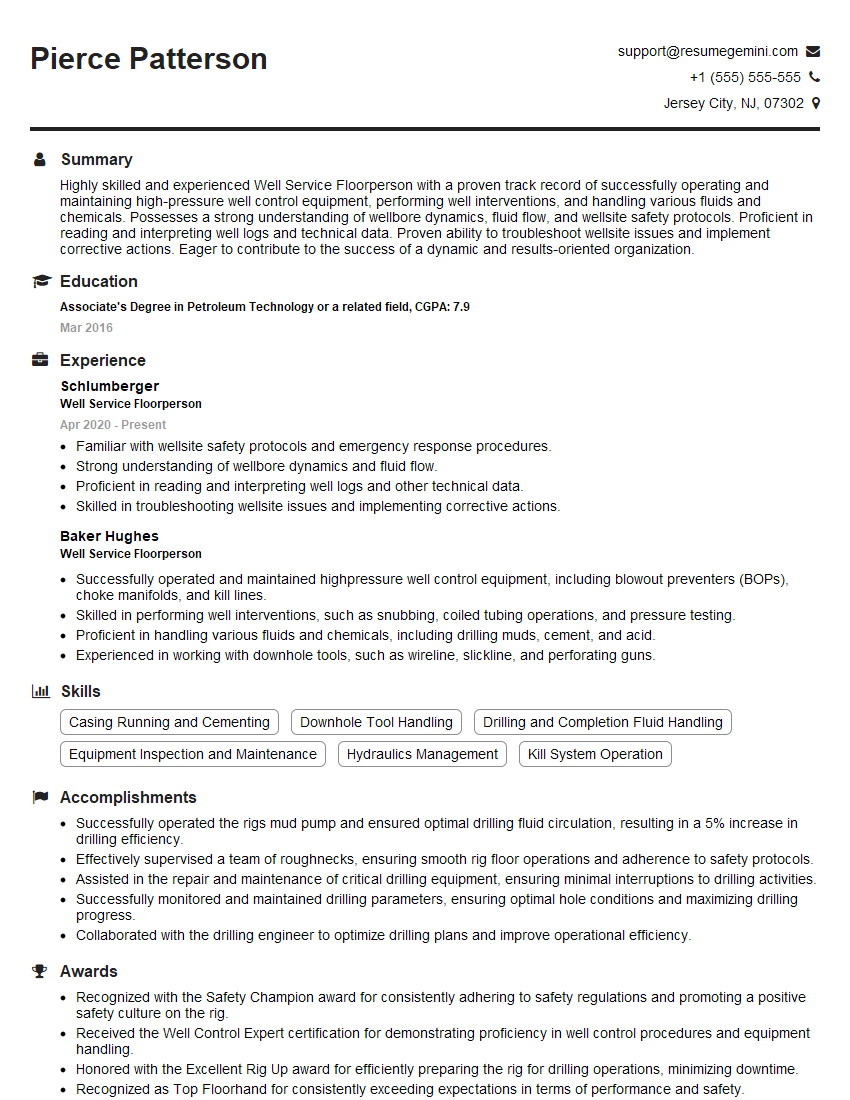

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Well Service Floorperson

1. Describe the role and responsibilities of a Well Service Floorperson?

As a Well Service Floorperson, I would be responsible for:

- Monitoring and controlling wellsite operations, including drilling, completion, and workover activities.

- Ensuring all safety regulations and procedures are followed to maintain a safe work environment.

- Operating and maintaining equipment, such as mud pumps, generators, and blowout preventers.

- Performing well servicing tasks, such as setting and retrieving tools, circulating fluids, and testing wellhead equipment.

- Assisting with wellsite maintenance and repairs.

2. Explain the key safety protocols to be observed on a wellsite?

: General Safety Protocols

- Always wear appropriate personal protective equipment (PPE), including hard hat, safety glasses, and gloves.

- Follow all posted safety signs and instructions.

- Stay aware of your surroundings and be alert to potential hazards.

- Do not operate equipment without proper training and authorization.

- Report any unsafe conditions or incidents immediately.

Subheading: Well Servicing Specific Protocols

- Ensure blowout preventers are properly installed and maintained.

- Follow established procedures for handling and storing hazardous materials.

- Be aware of the risks associated with pressure testing and other well servicing operations.

- Use proper lifting techniques and equipment when handling heavy objects.

- Never enter a confined space without proper ventilation and safety precautions.

3. What are the different types of fluids used in well servicing operations, and what are their purposes?

The different types of fluids used in well servicing operations include:

- Drilling fluids: Used to lubricate and cool the drill bit, remove cuttings, and control well pressure.

- Completion fluids: Used to fill the wellbore after drilling and to provide support for the casing.

- Workover fluids: Used to perform maintenance or repairs on existing wells.

- Test fluids: Used to test the integrity of the wellbore and its equipment.

4. Describe the operation and maintenance procedures for mud pumps?

Subheading: Operation

- Ensure mud pump is properly installed and connected to the wellbore.

- Check mud levels and add makeup fluid as needed.

- Start mud pump and adjust flow rate and pressure as per job requirements.

- Monitor mud pump performance and make adjustments as necessary.

Subheading: Maintenance

- Regularly inspect mud pump for leaks, wear, and damage.

- Lubricate moving parts and replace worn components as needed.

- Follow established maintenance schedules and perform preventive maintenance tasks.

- Keep a maintenance log to track repairs and replacements.

5. Explain the purpose and operation of blowout preventers?

Blowout preventers (BOPs) are critical safety devices used to prevent uncontrolled release of well fluids and gases in the event of a blowout. They work by sealing the wellbore and preventing the flow of hydrocarbons.

BOPs are typically installed in a stack on the wellhead. Each BOP has a specific function, such as:

- Annular preventer: Seals the annulus between the drill pipe and the wellbore.

- Ram preventer: Seals the wellbore by closing rams around the drill pipe or casing.

- Shear ram preventer: Cuts the drill pipe or casing in the event of a blowout.

6. What are the common causes of well control problems, and how can they be prevented or mitigated?

Common causes of well control problems include:

- Formation pressure exceeds wellbore pressure: Can be prevented by maintaining adequate mud weight and using appropriate drilling practices.

- Loss of circulation: Can be prevented by using proper drilling fluids and monitoring mud levels.

- Kick: An influx of formation fluids into the wellbore. Can be prevented by maintaining wellbore pressure and using blowout preventers.

- Blowout: An uncontrolled release of well fluids and gases. Can be mitigated by closing blowout preventers and taking appropriate emergency response measures.

7. What are the different methods for controlling well flow during drilling and completion operations?

Methods for controlling well flow include:

- Mud weight: The density of the drilling fluid helps to balance formation pressure and prevent influx of fluids.

- Casing: A steel pipe inserted into the wellbore to provide structural support and prevent fluid migration.

- Cement: A material pumped into the annulus between the casing and the wellbore to seal and strengthen the well.

- Blowout preventers: Safety devices that can be closed to seal the wellbore and prevent uncontrolled release of fluids.

8. How do you interpret well logs and what information can be obtained from them?

Well logs are graphical representations of data collected from sensors lowered into the wellbore. They provide valuable information about the geology, formation properties, and fluid content of the well.

Different types of well logs include:

- Gamma ray log: Measures the natural radioactivity of the formation.

- Neutron log: Measures the porosity of the formation.

- Density log: Measures the density of the formation.

- Resistivity log: Measures the electrical resistance of the formation.

9. Describe the different types of wellhead equipment and their functions?

Wellhead equipment includes:

- Christmas tree: A manifold that allows for control and regulation of well flow.

- Blowout preventers: Safety devices that can be closed to seal the wellbore and prevent uncontrolled release of fluids.

- Casing head: A housing that connects the casing to the wellhead.

- Tubing head: A housing that connects the tubing to the wellhead.

- Annular blowout preventer: Seals the annulus between the casing and the drill pipe or tubing.

10. What are the environmental regulations and safety protocols that must be followed during well servicing operations?

Environmental regulations and safety protocols for well servicing operations include:

- Proper disposal of waste materials: Drilling fluids, cuttings, and other waste materials must be disposed of in accordance with environmental regulations.

- Protection of water resources: Well servicing operations must be conducted in a manner that protects water resources from contamination.

- Air pollution control: Emissions from well servicing equipment must be controlled to minimize air pollution.

- Noise control: Noise levels from well servicing operations must be controlled to minimize disturbance to the surrounding community.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Well Service Floorperson.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Well Service Floorperson‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Well Service Floorpersons, also known as Field Service Technicians, are responsible for the maintenance and operation of well servicing equipment, including pumps, valves, and tanks. They work closely with engineers, geologists, and other specialists to ensure the safe and efficient operation of wells.

1. Maintain and Repair Equipment

Floorpersons are responsible for maintaining and repairing all equipment used in well servicing operations. This includes pumps, valves, tanks, and other equipment. They must be able to identify and troubleshoot problems with equipment, and make repairs quickly and efficiently.

- Inspect and maintain pumps, valves, tanks, and other equipment

- Troubleshoot and repair equipment problems

- Perform scheduled maintenance and repairs

2. Operate Equipment

Floorpersons are also responsible for operating well servicing equipment. This includes operating pumps, valves, and tanks. They must be able to operate equipment safely and efficiently, and follow all safety procedures.

- Operate pumps, valves, and tanks

- Follow all safety procedures

- Monitor equipment operation

3. Assist with Well Servicing Operations

Floorpersons assist with all aspects of well servicing operations. This includes preparing the well for servicing, installing and removing equipment, and cleaning up after the operation. They must be able to work as part of a team, and follow instructions from supervisors.

- Prepare the well for servicing

- Install and remove equipment

- Clean up after the operation

- Work as part of a team

4. Maintain Safety

Safety is a top priority in well servicing operations. Floorpersons must be aware of all safety procedures, and follow them at all times. They must also be able to identify and mitigate potential hazards.

- Follow all safety procedures

- Identify and mitigate potential hazards

- Wear appropriate personal protective equipment

Interview Tips

To ace your job interview for a Well Service Floorperson position, you can follow these tips:

1. Research the Company and Position

Before your interview, take some time to research the company and the specific well service floorperson position you are applying for. Learn about the company’s history, values, and mission. Also, be sure to review the job posting carefully and identify the key responsibilities and qualifications for the position.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked in a Well Service Floorperson interview. These questions may include:

- Tell me about your experience in well servicing.

- What are your strengths and weaknesses as a well service floorperson?

- Why are you interested in this position?

- What are your salary expectations?

- Do you have any questions for me?

Take some time to practice answering these questions. Be sure to tailor your answers to the specific job posting and company you are applying to.

3. Be Prepared to Discuss Your Safety Experience

Safety is a top priority in well servicing operations. In your interview, you will likely be asked about your safety experience and knowledge. Be sure to highlight your experience in following safety procedures and mitigating potential hazards. If you have any specific safety certifications, be sure to mention them.

4. Dress Appropriately

Dress professionally for your interview. This means wearing a suit or other business attire. First impressions matter, so making a good impression with your appearance is important.

5. Be Confident and Enthusiastic

Be confident and enthusiastic in your interview. This will show the interviewer that you are genuinely interested in the position and that you are a hard worker. Be sure to make eye contact with the interviewer and speak clearly. Also, be prepared to ask questions about the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Well Service Floorperson interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!