Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Longwall Headgate Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

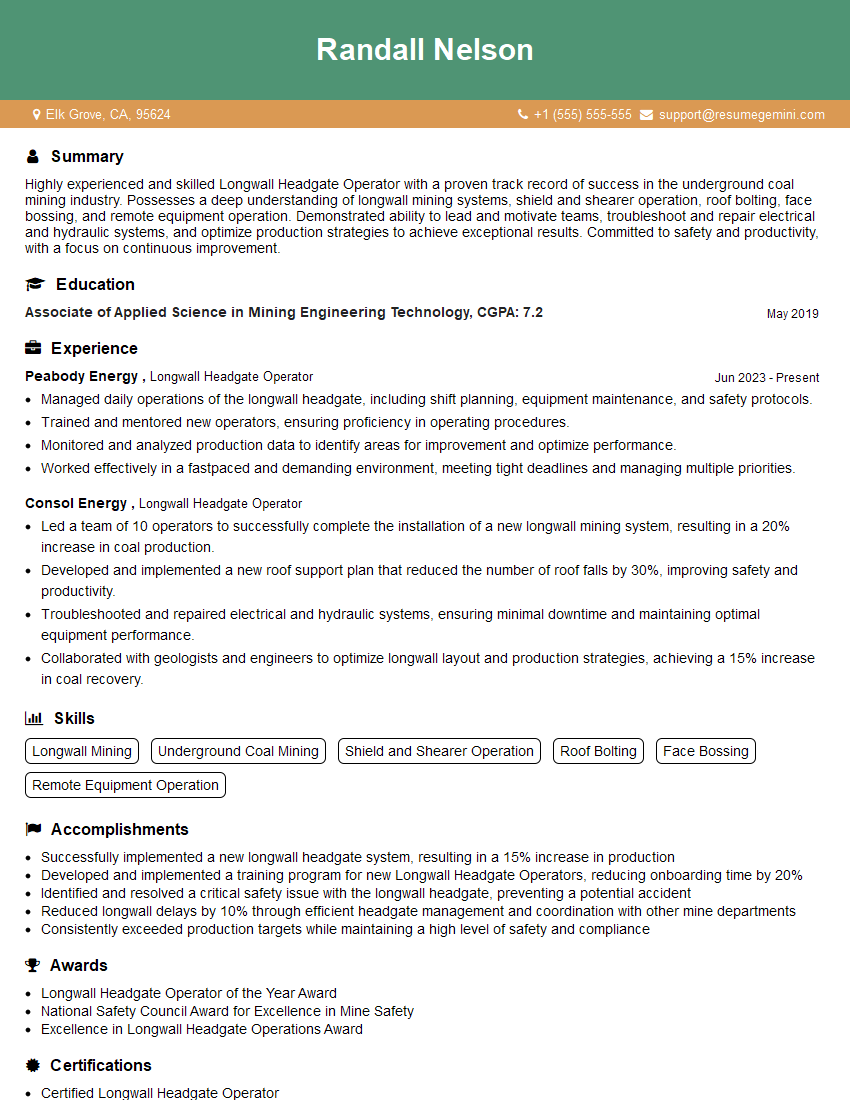

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Longwall Headgate Operator

1. Explain the key responsibilities of a Longwall Headgate Operator?

The key responsibilities of a Longwall Headgate Operator include:

- Operating and maintaining longwall headgate equipment, including shearers, AFCs, and face conveyors.

- Monitoring and adjusting machine settings to optimize production and efficiency.

- Identifying and troubleshooting equipment problems, and making necessary repairs.

- Ensuring that the headgate area is safe and compliant with all applicable regulations.

- Working closely with other members of the longwall team to achieve production goals.

2. Describe the different types of longwall headgate equipment?

Shearers

- Shearers are the machines that cut the coal from the face.

- They are typically equipped with a rotating drum that has cutting picks attached to it.

- Shearers can be either single-ended or double-ended.

AFCs (Armored Face Conveyors)

- AFCs are the conveyors that transport the coal from the face to the headgate.

- They are typically made up of a series of pans that are linked together.

- AFCs are powered by electric motors.

Face Conveyors

- Face conveyors are the conveyors that transport the coal from the headgate to the surface.

- They are typically made up of a series of belts that are linked together.

- Face conveyors are powered by electric motors.

3. What are the most common problems that you have encountered with longwall headgate equipment, and how did you resolve them?

The most common problems that I have encountered with longwall headgate equipment include:

- Shearer breakdowns

- AFC blockages

- Face conveyor problems

I have resolved these problems by:

- Troubleshooting the problem and identifying the root cause.

- Making the necessary repairs to the equipment.

- Working with other members of the longwall team to clear blockages and get the equipment back up and running.

4. What are the safety procedures that you must follow when working on longwall headgate equipment?

The safety procedures that I must follow when working on longwall headgate equipment include:

- Always wear the proper PPE, including a hard hat, safety glasses, and gloves.

- Never work on equipment that is not properly locked out and tagged out.

- Be aware of your surroundings and watch for any potential hazards.

- Never work alone, and always have a spotter when working on equipment.

- Follow all applicable company safety procedures.

5. What are the different types of maintenance that you perform on longwall headgate equipment?

The different types of maintenance that I perform on longwall headgate equipment include:

- Routine maintenance, such as greasing and oiling.

- Preventive maintenance, such as replacing worn parts and checking for potential problems.

- Corrective maintenance, such as repairing breakdowns.

6. What are the most important skills that a Longwall Headgate Operator should have?

The most important skills that a Longwall Headgate Operator should have include:

- Strong mechanical skills

- Ability to troubleshoot and repair equipment

- Working knowledge of longwall mining equipment

- Understanding of safety procedures

- Ability to work in a team environment

7. What are the career advancement opportunities for a Longwall Headgate Operator?

The career advancement opportunities for a Longwall Headgate Operator include:

- Longwall Section Foreman

- Longwall Maintenance Supervisor

- Longwall Mine Manager

8. What is your favorite thing about working as a Longwall Headgate Operator?

My favorite thing about working as a Longwall Headgate Operator is the challenge of keeping the equipment running smoothly and efficiently.

I also enjoy the camaraderie of working with my fellow longwall miners.

9. What is your greatest accomplishment as a Longwall Headgate Operator?

My greatest accomplishment as a Longwall Headgate Operator was when I was able to troubleshoot and repair a major breakdown on the shearer.

The breakdown was costing the company thousands of dollars per hour, and I was able to get the shearer back up and running within a few hours.

10. Why should we hire you as a Longwall Headgate Operator?

I have the skills and experience that you are looking for in a Longwall Headgate Operator.

I am a highly motivated and results-oriented individual with a strong commitment to safety.

I am confident that I can make a significant contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Longwall Headgate Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Longwall Headgate Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Longwall Headgate Operators are responsible for operating and maintaining longwall mining equipment, ensuring the safe and efficient extraction of coal from underground mines. The key job responsibilities include:

1. Operating Longwall Equipment

Operate and control longwall mining equipment, including shearers, roof supports, and conveyors, to extract coal from underground seams.

- Monitor and adjust equipment settings to optimize coal production and minimize downtime.

- Identify and resolve equipment malfunctions and perform basic repairs as needed.

2. Maintaining Equipment

Perform preventive maintenance and repairs on longwall equipment, including inspections, lubrication, and cleaning.

- Identify and report equipment issues to maintenance personnel for timely repairs.

- Maintain a clean and organized work area to ensure equipment safety and efficiency.

3. Safety and Compliance

Adhere to all safety regulations and follow established operating procedures to ensure a safe work environment.

- Monitor gas levels, roof conditions, and other safety hazards to protect personnel and equipment.

- Report any unsafe conditions or practices to supervisors and take corrective actions.

4. Communication and Coordination

Communicate effectively with supervisors, maintenance personnel, and other team members to coordinate activities.

- Provide updates on equipment status, production rates, and any issues encountered.

- Participate in safety meetings and drills to enhance teamwork and ensure compliance.

Interview Tips

Preparing thoroughly for an interview is crucial to showcasing your skills and experience and impressing the hiring manager. Here are some tips to help you ace your Longwall Headgate Operator interview:

1. Research the Company and Position

Demonstrate your interest in the company and the position by researching their website, industry news, and company culture. This knowledge will allow you to ask informed questions and convey your understanding of the role.

- Visit the company website to learn about their operations, goals, and values.

- Read industry publications or articles specific to longwall mining to stay up-to-date on current trends and technologies.

2. Highlight Your Relevant Experience and Skills

Focus on highlighting your experience and skills that are most relevant to the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact.

- Emphasize your experience operating and maintaining longwall equipment, including shearers, roof supports, and conveyors.

- Share examples of your ability to identify and resolve equipment malfunctions and perform basic repairs.

3. Prepare for Technical Questions

Anticipate technical questions related to longwall mining equipment and operations. Review common terminologies and concepts to ensure you can answer these questions confidently.

- Prepare to discuss different types of longwall equipment, their functions, and maintenance procedures.

- Be ready to explain how you monitor and adjust equipment settings to optimize production and minimize downtime.

4. Emphasize Safety and Compliance

Highlight your commitment to safety and adherence to safety regulations in the mining industry. Share examples of how you ensure a safe work environment.

- Describe your experience with gas monitoring, roof condition assessments, and hazard identification procedures.

- Explain how you communicate safety concerns and take corrective actions to prevent accidents.

5. Practice Your Communication Skills

Effective communication is vital in this role. Practice answering interview questions clearly and concisely, demonstrating your ability to convey technical information accurately.

- Rehearse your responses to common interview questions, such as “Tell me about your experience operating longwall equipment.”

- Use specific examples and quantifiable results to illustrate your accomplishments.

6. Ask Thoughtful Questions

Asking thoughtful questions during the interview shows that you are engaged and interested in the position. Prepare questions related to the company’s operations, safety protocols, or industry trends.

- Inquire about the company’s plans for expanding or improving their longwall mining operations.

- Ask about their commitment to employee training and development programs.

7. Follow Up Professionally

After the interview, send a thank-you note to the hiring manager, reiterating your interest in the position and key points discussed during the interview. This shows your gratitude and professionalism.

- Thank the hiring manager for their time and consideration.

- Re-emphasize your qualifications and how you can contribute to their organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Longwall Headgate Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.