Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spragger position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

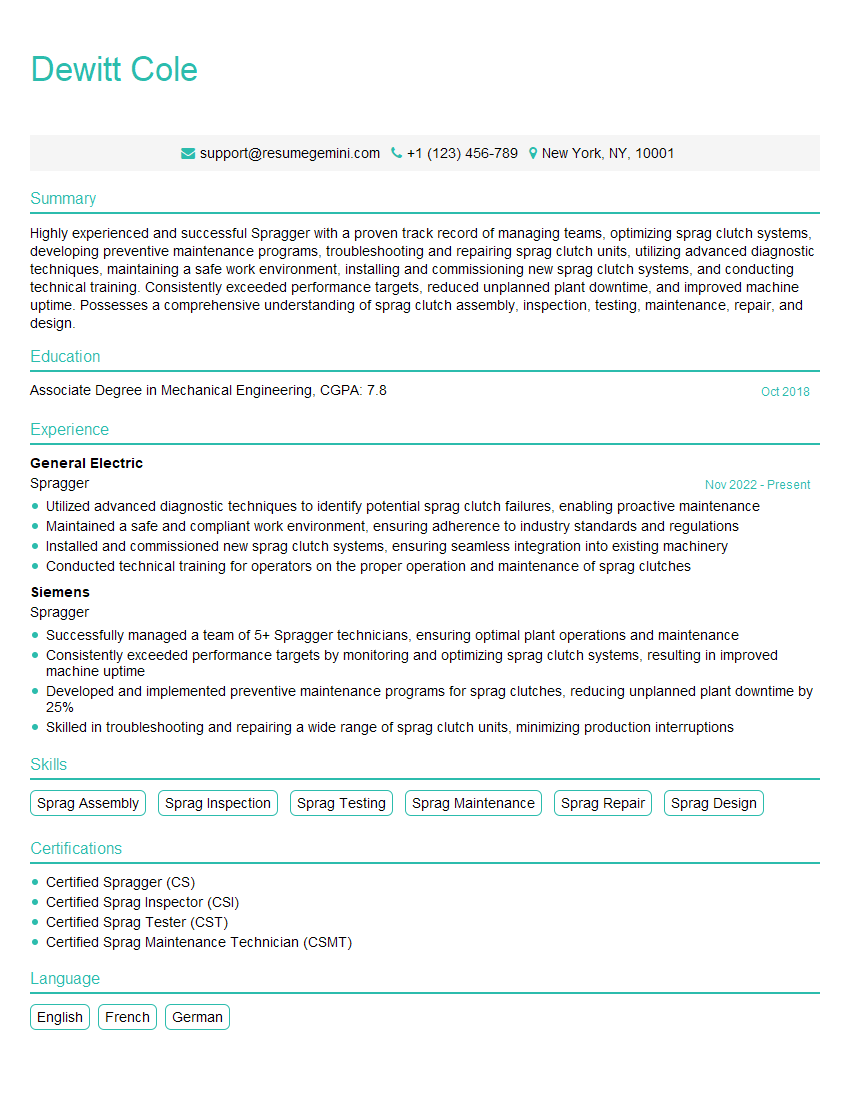

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spragger

1. What are the key technical skills required for a Spragger?

As a Spragger, I possess a comprehensive understanding of the technical skills necessary for the role. These include:

- Heavy Machinery Operation: Proficiency in operating various heavy machinery, including backhoes, excavators, and graders, for excavation, site preparation, and grading.

- Site Preparation: Expertise in preparing construction sites, including clearing land, removing debris, and leveling surfaces.

- Grading and Compaction: Understanding of grading techniques to ensure proper drainage and compaction of soil, using equipment like graders and rollers.

- Utility Installation: Experience in installing underground utilities such as water, sewer, and electrical lines, with knowledge of trenching and pipe-laying.

- Asphalt Paving: Familiarity with asphalt paving techniques, including mixing, laying, and compacting asphalt to create smooth and durable surfaces.

2. How do you approach excavation for a construction project?

Planning and Preparation

- Review project plans and specifications.

- Identify excavation requirements and determine appropriate equipment.

- Secure necessary permits and safety measures.

Excavation Execution

- Mark excavation boundaries accurately.

- Utilize proper excavation techniques, such as trenching, benching, or sloping.

- Ensure proper drainage and stabilization of excavated areas.

Safety and Quality Control

- Comply with all safety regulations and protocols.

- Monitor excavation progress and adjust techniques as necessary.

- Inspect completed excavation to ensure it meets specifications.

3. Describe the process of installing a sewer line.

- Trenching: Dig a trench of the appropriate depth and width for the sewer line, ensuring it slopes towards the discharge point.

- Pipe Placement: Lay the sewer pipes in the trench, ensuring they are properly aligned and connected.

- Bedding and Backfilling: Surround the pipes with bedding material to provide support, then backfill the trench with compacted soil.

- Compaction: Compact the soil around the sewer line to provide stability and prevent movement.

- Testing: Perform leak and pressure tests to verify the integrity of the sewer line.

4. How do you handle different soil conditions during grading?

When encountering different soil conditions during grading, I adjust my approach as follows:

- Sandy Soils: Use lighter equipment and avoid overcompaction to prevent displacement.

- Clay Soils: Allow for additional drying time and use heavier equipment for better compaction.

- Rocky Soils: Remove large rocks and boulders, and use specialized equipment such as rock breakers.

- Wet Soils: Improve drainage by installing perforated pipes or geotextile membranes, and use equipment with wider tires to distribute weight.

5. What safety measures do you prioritize while operating heavy machinery?

Safety is paramount when operating heavy machinery. I prioritize the following measures:

- PPE and Clothing: Wear appropriate personal protective equipment (PPE), including hard hat, safety glasses, reflective vest, and steel-toe boots.

- Machine Inspection: Conduct thorough pre-operational inspections to ensure all systems are functioning properly.

- Work Zone Safety: Establish clear boundaries around the work area using cones, barriers, and signage.

- Awareness and Communication: Maintain constant awareness of surroundings and communicate clearly with other crew members.

- Emergency Preparedness: Familiarize myself with emergency procedures and have necessary equipment, such as a fire extinguisher, readily available.

6. How do you ensure the quality of your work as a Spragger?

To ensure the quality of my work, I adhere to the following practices:

- Attention to Detail: Pay close attention to project plans, specifications, and safety protocols.

- Regular Inspections: Conduct regular inspections throughout the project to identify and address potential issues.

- Precision Grading: Utilize advanced grading techniques and equipment to achieve precise slopes and elevations.

- Compaction Testing: Perform compaction tests to ensure that soil meets specified density requirements.

- Customer Communication: Maintain open communication with the project team to ensure that expectations are met.

7. What is your experience with using GPS and laser leveling equipment in your work?

I have extensive experience in utilizing GPS and laser leveling equipment in my role as a Spragger:

- GPS for Excavation: Use GPS technology to accurately mark excavation boundaries, ensuring precise positioning and minimizing over-excavation.

- Laser Leveling for Grading: Employ laser leveling systems to create smooth and accurate grades, reducing the need for manual adjustments.

- Machine Control Integration: Integrate GPS and laser leveling systems with heavy machinery to automate grading and excavation tasks, enhancing efficiency and accuracy.

8. How do you handle unexpected weather conditions that may affect your work?

When faced with unexpected weather conditions that may impact my work as a Spragger, I take the following steps:

- Monitor Weather Forecasts: Regularly monitor weather forecasts to anticipate potential weather events.

- Contingency Planning: Develop contingency plans to adjust work schedules and utilize alternative methods in case of unfavorable weather.

- Safety First: Prioritize the safety of my crew and myself, suspending operations if conditions pose a risk.

- Equipment Protection: Take measures to protect machinery and equipment from adverse weather, such as covering them with tarps or moving them to sheltered areas.

9. Describe your experience in working on multiple projects simultaneously.

I have experience working on multiple projects simultaneously and managing my time effectively:

- Project Prioritization: Prioritize projects based on urgency, deadlines, and resource availability.

- Task Delegation: Delegate tasks to crew members based on their expertise and availability to ensure timely completion.

- Communication and Coordination: Maintain open communication with project managers and team members to coordinate schedules and avoid conflicts.

- Flexibility and Adaptability: Adapt to changing project demands and adjust work plans as necessary to meet deadlines.

10. What is your approach to teamwork and collaboration in your role as a Spragger?

As a Spragger, I value teamwork and collaboration to achieve project success:

- Cooperative Environment: Foster a cooperative work environment where team members support and assist each other.

- Clear Communication: Communicate effectively with crew members and other project stakeholders to avoid misunderstandings and ensure smooth operations.

- Shared Responsibility: Embracing shared responsibility for project outcomes, contributing ideas, and supporting team decisions.

- Respect for Diverse Skills: Respect and leverage the diverse skills and experiences of team members to maximize collective output.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spragger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spragger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spragger is a crucial position in the manufacturing industry. They are responsible for operating and maintaining sprag clutches, which are mechanical devices that allow for the transmission of torque in one direction while preventing it in the opposite direction.

1. Installation and Maintenance

Install and maintain sprag clutches, ensuring they meet operational standards.

- Adhere to safety protocols and industry guidelines.

- Identify and resolve any issues with sprag clutches.

2. Troubleshooting and Repair

Diagnose and repair malfunctions in sprag clutches.

- Use specialized tools and techniques to identify and fix problems.

- Conduct performance tests to ensure proper functioning.

3. Lubrication and Inspection

Lubricate and inspect sprag clutches regularly.

- Follow maintenance schedules and procedures.

- Maintain records of all inspections and repairs.

4. Training and Supervision

Train and supervise other technicians on sprag clutch operations and maintenance.

- Provide guidance and support to ensure safe and efficient work practices.

- Monitor performance and provide feedback for improvement.

Interview Tips

To ace the interview for a Spragger position, candidates should prepare thoroughly and demonstrate their knowledge and skills.

1. Research the company and the position

Familiarize yourself with the company’s history, values, and products. Understand the specific responsibilities and requirements of the Spragger role.

- Visit the company’s website and social media pages

- Read industry publications and articles

2. Practice your answers to common interview questions

Prepare your responses to questions about your experience, skills, and why you are interested in the position. Use the STAR method (Situation, Task, Action, Result) to provide clear and concise answers.

- Tell me about a time you successfully diagnosed and repaired a sprag clutch malfunction.

- Describe your experience in training and supervising other technicians.

3. Highlight your knowledge of sprag clutches

Emphasize your understanding of sprag clutch principles, operation, and maintenance procedures. Be prepared to discuss different types of sprag clutches and their applications.

- Explain the working principle of a sprag clutch

- Discuss the importance of proper lubrication for sprag clutches

4. Demonstrate your problem-solving and analytical skills

Spraggers are often required to troubleshoot and resolve complex problems. Provide examples of how you have used your analytical and problem-solving abilities in previous roles.

- Describe a challenging situation where you identified and resolved a problem with a sprag clutch

- Explain how you analyze data to identify potential issues with sprag clutches

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spragger interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.