Are you gearing up for an interview for a Gear Repair Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Gear Repair Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

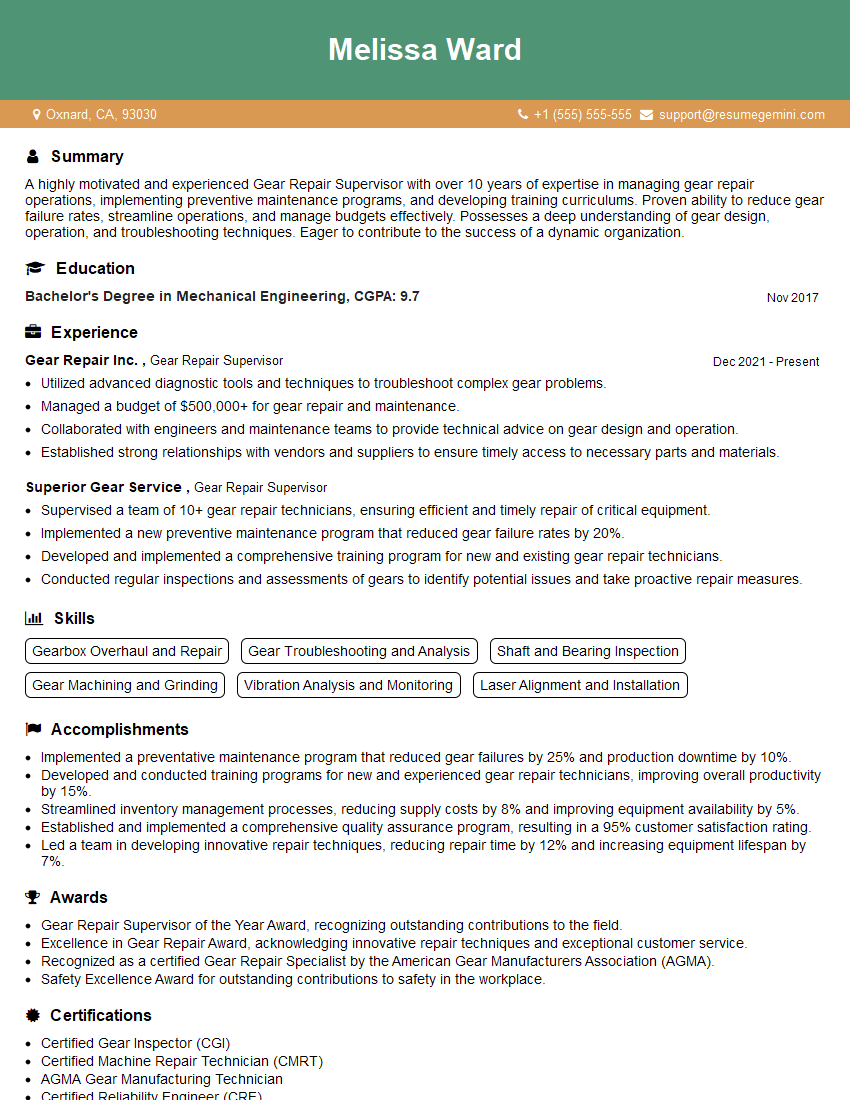

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Repair Supervisor

1. Explain the process of gear inspection and evaluation?

The process of gear inspection and evaluation involves several key steps:

- Visual inspection: This involves examining the gear for any visible defects such as cracks, burrs, or pitting.

- Dimensional inspection: This involves measuring the gear’s dimensions to ensure they meet specifications.

- Surface inspection: This involves examining the gear’s surface finish to ensure it is smooth and free of defects.

- Functional testing: This involves testing the gear in a simulated operating environment to ensure it functions properly.

2. What are the common types of gear defects and how do you identify them?

Types of gear defects:

- Tooth damage: Such as pitting, spalling, or breakage.

- Bearing damage: Such as wear, vibration, or noise.

- Lubrication problems: Such as insufficient lubrication or contamination.

- Alignment problems: Such as misalignment between gears or shafts.

How to identify defects:

- Visual inspection: Looking for visible signs of damage or wear.

- Dimensional inspection: Measuring the gear’s dimensions to identify any deviations from specifications.

- Surface inspection: Examining the gear’s surface finish to identify any roughness or defects.

- Functional testing: Testing the gear in a simulated operating environment to identify any functional problems.

3. How do you ensure the quality of gear repairs?

To ensure the quality of gear repairs, I follow a comprehensive quality assurance process which includes:

- Inspection and evaluation: Inspecting the gear before and after repair to identify any defects.

- Proper repair techniques: Using the appropriate repair techniques and materials to ensure the repair is durable and effective.

- Testing and validation: Testing the repaired gear in a simulated operating environment to ensure it functions properly.

- Documentation: Maintaining detailed records of the repair process, including inspection results, repair methods, and test results.

4. What are the different methods of gear repair and when would you use each method?

The choice of gear repair method depends on the type and severity of the damage.

- Welding: Used to repair cracks, broken teeth, or other damage to the gear’s surface.

- Machining: Used to restore the gear’s dimensions or surface finish.

- Coating: Used to protect the gear’s surface from wear or corrosion.

- Replacement: Used when the damage is too severe to repair or when the cost of repair is excessive.

5. How do you manage a team of gear repair technicians?

To manage a team of gear repair technicians, I use a combination of leadership, communication, and technical expertise:

- Leadership: Providing clear direction, motivation, and support to the team.

- Communication: Keeping the team informed about goals, progress, and any changes to the repair process.

- Technical expertise: Providing guidance and support to the team on technical issues and repair procedures.

- Training and development: Ensuring the team has the necessary skills and knowledge to perform their jobs effectively.

6. How do you stay up-to-date on the latest gear repair techniques and technologies?

To stay up-to-date on the latest gear repair techniques and technologies, I:

- Attend industry conferences and workshops: To learn about new developments and best practices.

- Read industry publications and journals: To stay informed about the latest research and innovations.

- Network with other gear repair professionals: To exchange ideas and share knowledge.

- Participate in online forums and discussion groups: To stay connected with the global gear repair community.

7. What are the safety protocols that you follow when working with gears?

When working with gears, I follow strict safety protocols to prevent accidents and injuries:

- Wear appropriate safety gear: Such as gloves, eye protection, and hearing protection.

- Inspect equipment before use: To ensure it is in good working condition.

- Follow proper lockout/tagout procedures: To prevent accidental startup of equipment.

- Be aware of potential hazards: Such as sharp edges, moving parts, and hot surfaces.

- Never work alone: Always have a coworker present in case of an emergency.

8. How do you handle customer complaints and ensure customer satisfaction?

To handle customer complaints and ensure customer satisfaction, I:

- Listen attentively to the customer’s concerns: To understand their needs and expectations.

- Investigate the issue thoroughly: To identify the root cause of the problem.

- Propose a solution that meets the customer’s needs: And is within the company’s policies.

- Communicate the solution clearly to the customer: And keep them updated on the progress of the repair.

- Follow up with the customer after the repair is complete: To ensure their satisfaction.

9. What is your approach to continuous improvement in the gear repair process?

I believe in continuous improvement and use the following approach:

- Identify areas for improvement: By regularly reviewing the gear repair process and customer feedback.

- Develop and implement improvement plans: To address identified areas for improvement.

- Monitor and evaluate the results: To ensure the improvement plans are effective.

- Make adjustments as needed: To optimize the gear repair process and enhance customer satisfaction.

10. Why are you interested in this Gear Repair Supervisor position?

I am interested in this Gear Repair Supervisor position because it aligns with my skills, experience, and career goals. I have a proven track record of success in gear repair, and I am confident that I can use my expertise to lead and motivate your team to achieve even greater results. I am also eager to contribute to the continuous improvement of the gear repair process and to ensure that your customers receive the highest quality of service.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Repair Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Repair Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Repair Supervisors are responsible for overseeing the repair and maintenance of gears and gear systems. They ensure that all gears are in good working order and meet the required specifications. Gear Repair Supervisors also train and supervise other gear repair technicians.

1. Manage and coordinate the repair and maintenance of gear systems

Gear systems are integral components of various industrial machinery, from wind turbines to mining equipment. Gear Repair Supervisors must have a deep understanding of gear systems, their components, and how they function together. They must also be able to identify, diagnose, and repair any issues that may arise with gear systems.

- Oversee the repair and maintenance of gear systems

- Ensure that all gears are in good working order

- Meet the required specifications

- Train and supervise other gear repair technicians

2. Supervise and train other gear repair technicians

Gear Repair Supervisors are responsible for training and supervising other gear repair technicians. They must be able to effectively communicate technical information and instructions to their team. They must also be able to provide feedback and guidance to help technicians develop their skills and knowledge.

- Train and supervise other gear repair technicians

- Provide feedback and guidance

- Help technicians develop their skills and knowledge

- Communicate technical information and instructions

3. Maintain a safe and productive work environment

Gear Repair Supervisors must be able to maintain a safe and productive work environment for their team. They must be familiar with all safety regulations and procedures, and they must be able to enforce them effectively. They must also be able to identify and mitigate any potential hazards in the workplace.

- Maintain a safe and productive work environment

- Be familiar with all safety regulations and procedures

- Enforce safety regulations and procedures

- Identify and mitigate any potential hazards in the workplace

4. Stay up-to-date on the latest gear repair techniques and technologies

The field of gear repair is constantly evolving, and Gear Repair Supervisors must stay up-to-date on the latest techniques and technologies. They must be able to incorporate new knowledge into their work, and they must be able to train their team on new procedures. They must also be able to troubleshoot problems and find innovative solutions.

- Stay up-to-date on the latest gear repair techniques and technologies

- Incorporate new knowledge into work

- Train team on new procedures

- Troubleshoot problems and find innovative solutions

Interview Tips

Preparing for an interview for a Gear Repair Supervisor position can be challenging. Here are some tips to help you ace the interview and land the job.

1. Research the company and the position

Before you go on an interview, it is important to do your research. Learn about the company, its culture, and its products or services. You should also learn as much as you can about the Gear Repair Supervisor position. This will help you to answer questions thoughtfully and intelligently during the interview.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work for the company

- Identify specific qualities that make you the best candidate for the job

- Utilize “tell me about yourself” as an opportunity to explain your background and career qualifications.

2. Prepare for common interview questions

There are some common interview questions that you are likely to be asked during an interview for a Gear Repair Supervisor position. These questions may include:

- Tell me about your experience in gear repair.

- What are your strengths and weaknesses as a gear repair supervisor?

- How do you stay up-to-date on the latest gear repair techniques and technologies?

- What are your goals for your career in gear repair?

- Understand what each question reveals about the interviewer’s priorities.

- Practice answering the questions to demonstrate your knowledge, skills, and experience.

- Use the STAR method to answer questions.

3. Be confident and enthusiastic

It is important to be confident and enthusiastic during your interview. This will show the interviewer that you are passionate about gear repair and that you are eager to get the job. Be sure to make eye contact with the interviewer and to speak clearly and confidently. Ask thoughtful questions and demonstrate your interest in the company and the position.

- Dress professionally and arrive on time for your interview.

- Greet the interviewer with a firm handshake.

- Speak clearly and confidently.

- Be polite and respectful to everyone you meet.

- Thank the interviewer for their time at the end of the interview.

4. Follow up after the interview

After your interview, it is important to follow up with the interviewer. This shows that you are interested in the position and that you are eager to learn more. You can send a thank-you note or an email to the interviewer, reiterating your interest in the position and thanking them for their time. You can also ask the interviewer if they have any questions for you or if there is anything else you can provide them with.

- Send a thank-you note within 24 hours of the interview.

- Reiterate your interest in the position.

- Thank the interviewer for their time.

- Ask the interviewer if they have any questions for you.

- Respond promptly to any communications from the interviewer.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Gear Repair Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Gear Repair Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.