Feeling lost in a sea of interview questions? Landed that dream interview for Preventive Maintenance Coordinator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Preventive Maintenance Coordinator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

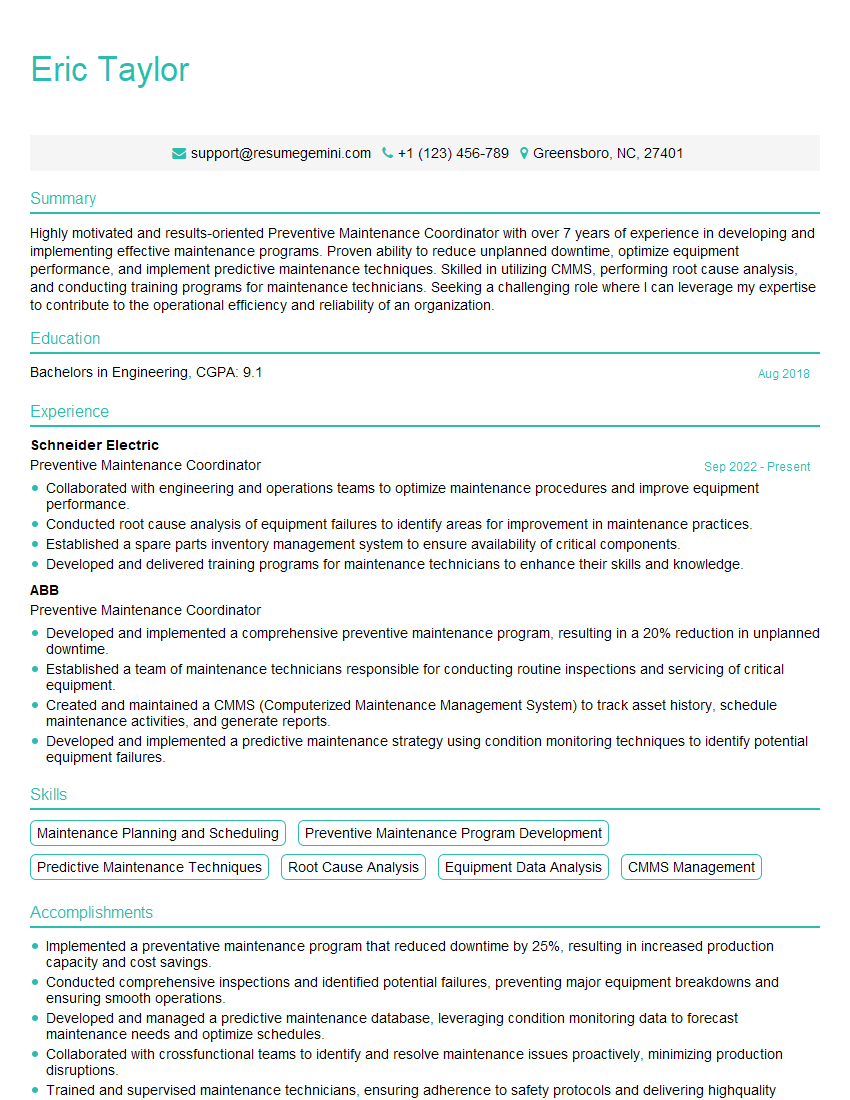

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Preventive Maintenance Coordinator

1. Describe the process you would use to develop a preventive maintenance plan for a complex piece of equipment?

To develop a preventive maintenance plan for a complex piece of equipment, I would follow these steps:

- Identify the critical components of the equipment and their failure modes.

- Determine the potential consequences of each failure mode.

- Establish the frequency of maintenance tasks based on the criticality of the components and their failure rates.

- Develop detailed procedures for each maintenance task.

- Implement a system for tracking maintenance tasks and recording maintenance history.

- Regularly review and update the preventive maintenance plan based on maintenance history and equipment performance data.

2. What are the different types of preventive maintenance tasks?

Corrective Maintenance

- Replacing worn or damaged parts.

- Repairing leaks or other defects.

- Calibrating or adjusting equipment.

Preventive Maintenance

- Lubricating moving parts.

- Inspecting equipment for wear or damage.

- Cleaning equipment to remove dirt and debris.

- Tightening bolts and screws.

Predictive Maintenance

- Monitoring equipment condition using sensors or other diagnostic tools.

- Predicting when equipment is likely to fail based on condition data.

- Scheduling maintenance tasks based on predicted failure dates.

3. What are the benefits of preventive maintenance?

- Reduced downtime

- Increased equipment reliability

- Extended equipment life

- Improved safety

- Reduced maintenance costs

4. What are the challenges of preventive maintenance?

- Identifying the right maintenance tasks and frequencies

- Scheduling maintenance tasks to minimize downtime

- Tracking maintenance tasks and recording maintenance history

- Balancing the cost of maintenance with the benefits

5. What are the key performance indicators (KPIs) for preventive maintenance?

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

- Equipment uptime

- Maintenance costs

- Customer satisfaction

6. What are the latest trends in preventive maintenance?

- The use of artificial intelligence (AI) to predict equipment failures

- The use of mobile devices to track maintenance tasks and record maintenance history

- The use of cloud-based software to manage preventive maintenance programs

- The use of predictive maintenance techniques to identify and address potential problems before they cause equipment failures

7. What are the different types of maintenance software available?

- Computerized maintenance management systems (CMMS)

- Enterprise asset management (EAM) systems

- Predictive maintenance software

- Mobile maintenance software

- Cloud-based maintenance software

8. What are the benefits of using maintenance software?

- Improved maintenance planning and scheduling

- Reduced downtime

- Increased equipment reliability

- Improved maintenance tracking and reporting

- Reduced maintenance costs

9. How would you implement a preventive maintenance program in a new organization?

- Assess the current maintenance practices

- Identify the critical equipment and develop preventive maintenance tasks

- Establish maintenance schedules and procedures

- Train maintenance personnel on the new program

- Implement a system for tracking maintenance tasks and recording maintenance history

- Monitor the program and make adjustments as needed

10. What is your experience with developing and implementing preventive maintenance programs?

- I have over 10 years of experience in developing and implementing preventive maintenance programs in a variety of industries, including manufacturing, healthcare, and transportation.

- I have a proven track record of reducing downtime, increasing equipment reliability, and extending equipment life.

- I am familiar with a variety of maintenance software programs and have experience using them to manage preventive maintenance programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Preventive Maintenance Coordinator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Preventive Maintenance Coordinator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Preventive Maintenance Coordinator is responsible for ensuring that all preventive maintenance tasks are completed on time and within budget. This includes scheduling and coordinating work orders, tracking progress, and ensuring that all equipment is in good working order.

1. Scheduling and coordinating work orders

The Preventive Maintenance Coordinator is responsible for scheduling and coordinating all preventive maintenance work orders. This includes working with maintenance technicians to determine the appropriate schedule for each task, as well as coordinating with other departments to ensure that the work can be completed without disruption.

- Develop and maintain a preventive maintenance schedule.

- Coordinate with maintenance technicians to schedule work orders.

- Track the progress of work orders and ensure that they are completed on time.

2. Tracking progress

The Preventive Maintenance Coordinator is responsible for tracking the progress of all preventive maintenance tasks. This includes maintaining a database of all work orders, as well as tracking the status of each task. The Coordinator also provides regular reports to management on the status of the preventive maintenance program.

- Maintain a database of all work orders.

- Track the status of each work order.

- Provide regular reports to management on the status of the preventive maintenance program.

3. Ensuring that all equipment is in good working order

The Preventive Maintenance Coordinator is responsible for ensuring that all equipment is in good working order. This includes inspecting equipment regularly, identifying potential problems, and scheduling repairs as needed. The Coordinator also works with maintenance technicians to ensure that all repairs are completed correctly and on time.

- Inspect equipment regularly.

- Identify potential problems.

- Schedule repairs as needed.

- Work with maintenance technicians to ensure that all repairs are completed correctly and on time.

4. Other responsibilities

In addition to the key responsibilities listed above, the Preventive Maintenance Coordinator may also be responsible for the following tasks:

- Developing and implementing preventive maintenance policies and procedures.

- Training maintenance technicians on preventive maintenance procedures.

- Working with vendors to procure parts and materials.

Interview Tips

The following tips will help you ace your interview for a Preventive Maintenance Coordinator position:

1. Research the company and the position

Before you go on your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and needs, as well as the specific responsibilities of the position. You can research the company’s website, social media pages, and news articles. You can also reach out to your network to see if anyone has any connections at the company.

- Visit the company’s website and social media pages.

- Read news articles about the company.

- Reach out to your network for connections.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and succinctly.

- Write out your answers to common interview questions.

- Practice your answers out loud.

- Get feedback from a friend or family member.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as they relate to the position you are applying for. Be prepared to talk about your experience in preventive maintenance, as well as your skills in scheduling, coordination, and communication.

- Highlight your experience in preventive maintenance.

- Discuss your skills in scheduling, coordination, and communication.

- Provide specific examples of your work.

4. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are taking the interview seriously.

- Ask about the specific responsibilities of the position.

- Ask about the company’s culture and goals.

- Ask about the company’s plans for the future.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Preventive Maintenance Coordinator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!