Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Duplicating Machine Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Duplicating Machine Mechanic so you can tailor your answers to impress potential employers.

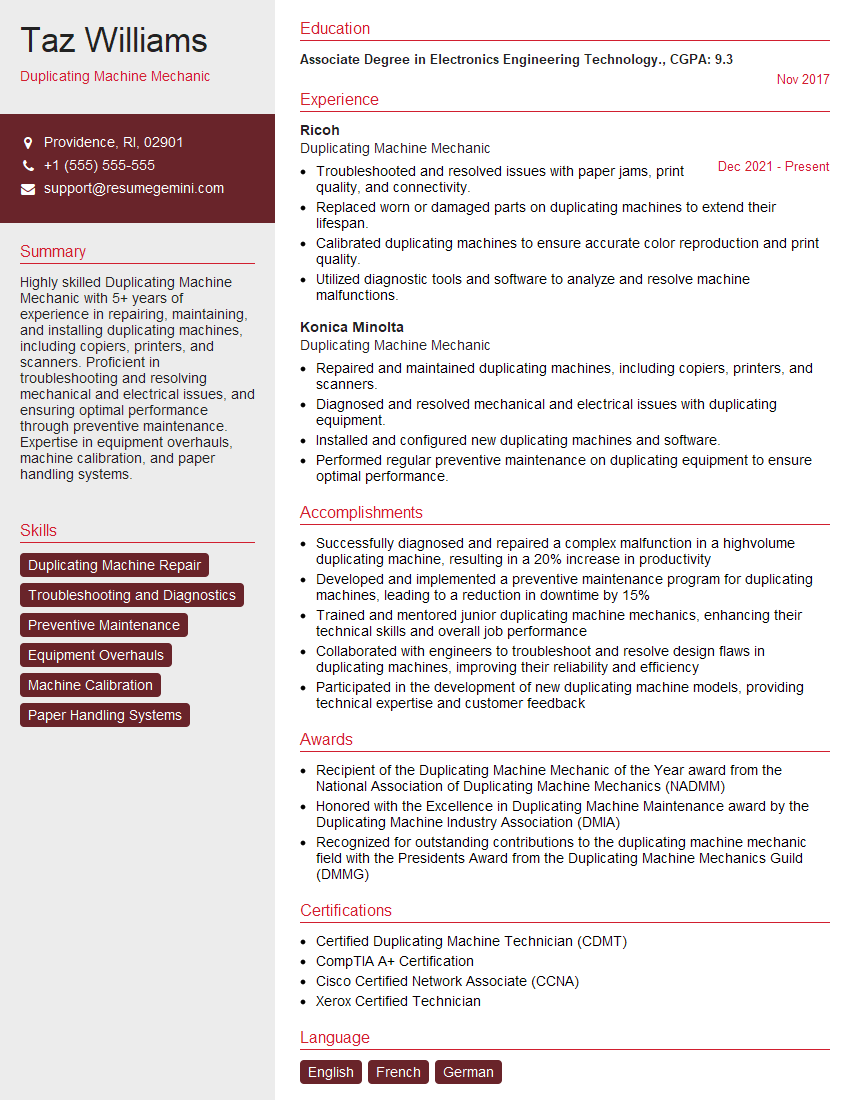

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Duplicating Machine Mechanic

1. What are the common types of duplicating machines and their key differences?

- Offset duplicators: Use a metal plate to transfer ink to paper, producing high-quality prints.

- Digital duplicators: Use digital technology to create masters and print copies, offering fast and cost-effective printing.

- Stencil duplicators: Employ a wax-coated stencil to create copies, suitable for low-volume printing.

- Spirit duplicators: Use a master with a specially treated surface to produce copies, ideal for short-run printing.

2. Describe the key steps involved in performing preventive maintenance on a duplicating machine.

Lubrication

- Identify and lubricate all moving parts, including gears, bearings, and chains.

- Use the recommended lubricants and follow the manufacturer’s instructions.

Cleaning

- Remove dust, paper particles, and other debris from all surfaces.

- Clean the paper feed mechanism, rollers, and print head thoroughly.

Inspection

- Check for worn or damaged parts.

- Inspect belts, hoses, and electrical connections.

Testing

- Run test prints to ensure proper operation.

- Check print quality, alignment, and functionality.

3. How would you diagnose and troubleshoot a duplicating machine that is producing smeared copies?

- Check the print head: Clean or replace the print head if it is clogged or damaged.

- Adjust the paper feed: Ensure that the paper is being fed correctly and not causing smudging.

- Inspect the fuser: Check the temperature and pressure of the fuser, as incorrect settings can cause smearing.

- Examine the toners: Make sure that the toners are of high quality and compatible with the machine.

- Test the rollers: Worn or dirty rollers can cause paper jams and smearing.

4. What are the key safety precautions to observe when working on duplicating machines?

- Unplug the machine: Always disconnect the power before performing any maintenance or repairs.

- Wear appropriate clothing: Avoid loose clothing or jewelry that could get caught in the machine.

- Use caution with sharp objects: Be careful when handling blades or other sharp parts.

- Avoid touching hot surfaces: Allow the machine to cool down before handling any components that may be hot.

- Follow manufacturer’s instructions: Refer to the user manual for specific safety guidelines.

5. How do you stay up-to-date on the latest duplicating machine technologies and best practices?

- Attend industry conferences and workshops: Learn about new products, techniques, and advancements.

- Read trade magazines and online resources: Stay informed about industry trends and best practices.

- Connect with other professionals: Network with colleagues to share knowledge and experiences.

- Enroll in manufacturer training programs: Enhance technical skills and stay abreast of product updates.

6. What are some common challenges faced by duplicating machine mechanics and how do you overcome them?

Technical complexity:

- Solution: Stay updated on the latest technologies, receive manufacturer training, and consult with experienced professionals.

Time constraints:

- Solution: Prioritize tasks, delegate responsibilities, and utilize efficient troubleshooting techniques.

Varied workload:

- Solution: Embrace versatility, develop a wide range of skills, and maintain a flexible work style.

7. Describe a situation where you successfully repaired a complex duplicating machine issue.

- Diagnosed the problem: Analyzed the symptoms, ran diagnostic tests, and identified the faulty component.

- Ordered and replaced the part: Procured the necessary parts and ensured compatibility.

- Calibrated and tested the machine: Fine-tuned the settings and performed thorough testing to ensure optimal performance.

- Documented the repair: Kept detailed records of the issue, resolution, and any additional observations.

8. How do you prioritize your workload and manage multiple tasks effectively?

- Use a task management system: Track tasks, set deadlines, and assign priorities.

- Break down large tasks: Divide complex projects into smaller, manageable steps.

- Delegate responsibilities: Assign tasks to capable team members to optimize efficiency.

- Communicate regularly: Keep stakeholders informed of progress, potential delays, and any changes in priority.

9. What are some key qualities that make a successful duplicating machine mechanic?

- Technical expertise: Strong understanding of duplicating machine principles, components, and troubleshooting techniques.

- Problem-solving skills: Ability to diagnose and resolve complex technical issues efficiently and effectively.

- Customer service orientation: Excellent communication and interpersonal skills to handle customer inquiries and provide support.

- Attention to detail: Meticulous and thorough approach to ensure accurate repairs and maintenance.

- Adaptability: Flexibility to handle a variety of tasks and work in different environments.

10. Do you have any questions for me about the position or the company?

This is an opportunity for you to demonstrate your interest in the position and the company. Ask thoughtful questions to gain more insights and show that you are genuinely interested in the opportunity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Duplicating Machine Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Duplicating Machine Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Duplicating Machine Mechanics, also known as Copy Machine Repair Technicians, are responsible for installing, maintaining, and repairing duplicating machines. They are also responsible for providing customer service and support. Some of the key job responsibilities include:

1. Installing and Setting up Duplicating Machines

Duplicating Machine Mechanics are responsible for installing and setting up duplicating machines according to the manufacturer’s specifications. They must ensure that the machines are properly leveled, calibrated, and connected to the correct power supply. They must also test the machines to ensure that they are functioning properly.

2. Troubleshooting and Repairing Duplicating Machines

Duplicating Machine Mechanics are responsible for troubleshooting and repairing duplicating machines that are experiencing problems. They must be able to diagnose the problem and determine the best course of action to repair the machine. They must also be able to order and replace parts as necessary.

3. Providing Customer Service and Support

Duplicating Machine Mechanics are responsible for providing customer service and support to customers who are experiencing problems with their duplicating machines. They must be able to answer questions, troubleshoot problems, and schedule service calls. They must also be able to provide training on how to use and maintain duplicating machines.

4. Maintaining Inventory

Duplicating Machine Mechanics are responsible for maintaining inventory of parts and supplies. They must ensure that the inventory is well-stocked and that all parts are in good condition. They must also be able to order parts and supplies as necessary.

Interview Tips

Preparing for a Duplicating Machine Mechanic interview can be daunting, but there are some things you can do to increase your chances of success. Here are a few interview tips and hacks:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate. You can also use this information to tailor your answers to the interviewer’s questions.

2. Practice Answering Interview Questions

One of the best ways to prepare for an interview is to practice answering common interview questions. You can do this by yourself or with a friend or family member. The more you practice, the more confident you will be during your actual interview. Here are some common interview questions for Duplicating Machine Mechanics:

- Tell me about your experience installing and repairing duplicating machines.

- What is your troubleshooting process?

- How do you provide customer service and support to customers?

- What is your experience with maintaining inventory?

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

4. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and be enthusiastic during your interview. The interviewer wants to get to know the real you and see if you are a good fit for the position. So be yourself and show the interviewer why you are the best candidate for the job.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Duplicating Machine Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Duplicating Machine Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.